vacuum pump

A technology of vacuum pump and air outlet, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of inability to adapt to use, affecting the vacuum degree of the vacuum pump, and reducing the volume, so as to achieve a small occupied space and improve installation efficiency. , the effect of saving installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

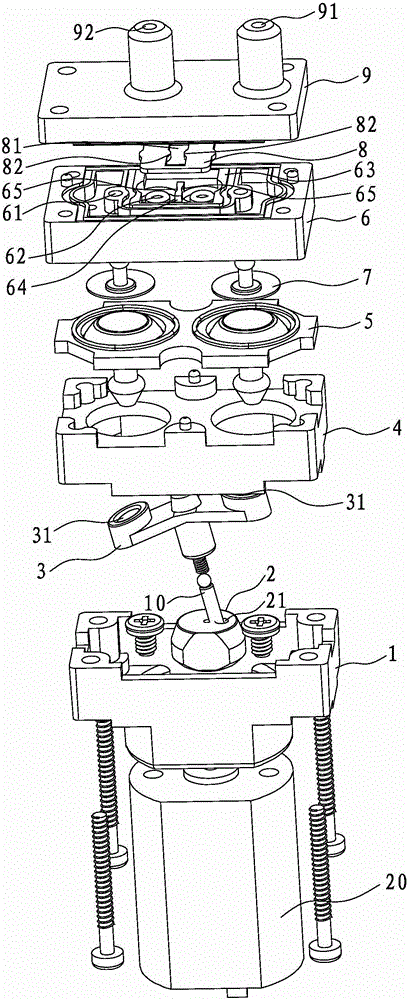

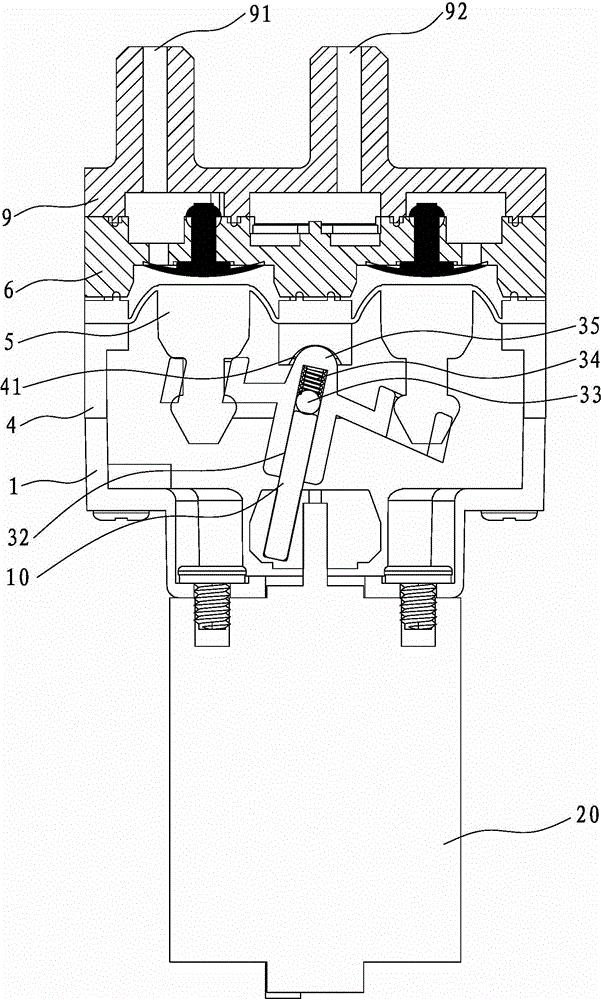

[0038] refer to figure 1 and figure 2 As shown, the vacuum pump disclosed by the present invention includes a housing 1, a cam 2, a curved rod 3, a support 4, an air bag 5, a valve seat 6, an umbrella-shaped one-way valve 7, a pressing piece 8, a top cover 9, and a connecting rod 10 And motor 20.

[0039] The motor 20 is installed in the casing 1 , the cam 2 is installed on the rotating shaft of the motor 20 , and the cam 2 is provided with an eccentric hole 21 .

[0040] The connecting rod 10 is placed in the eccentric hole 21 and connected with the curved rod 3 . A central shaft hole 32 can be set on the curved rod 3, and a spring 34 and a ball 33 are put into the shaft hole 32 successively. One end of the connecting rod 10 is inserted in the central shaft hole 32, and the other end is inserted in the eccentric hole 21 of the cam 2. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com