Steering gear pump

A steering gear and driving gear technology, applied in the direction of rotary piston pumps, pumps, pump components, etc., can solve the problems of being in a high temperature state, affecting the service life of the oil pump, and the heat can not be dissipated normally, so as to reduce the body surface temperature and increase the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

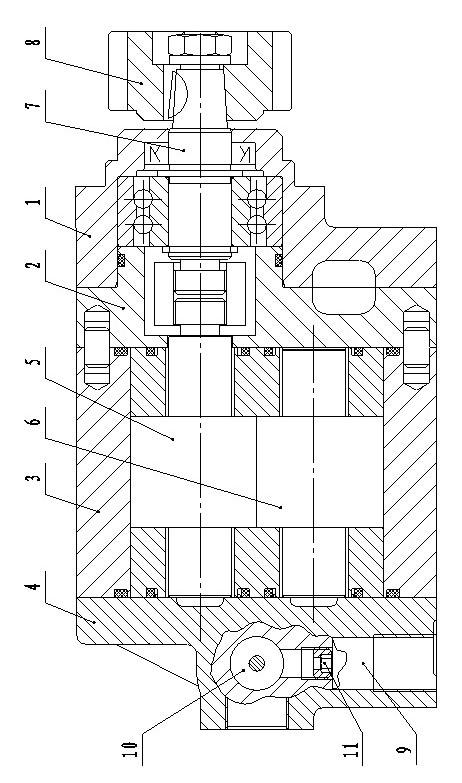

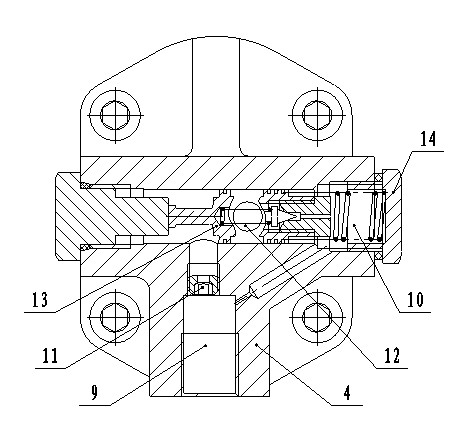

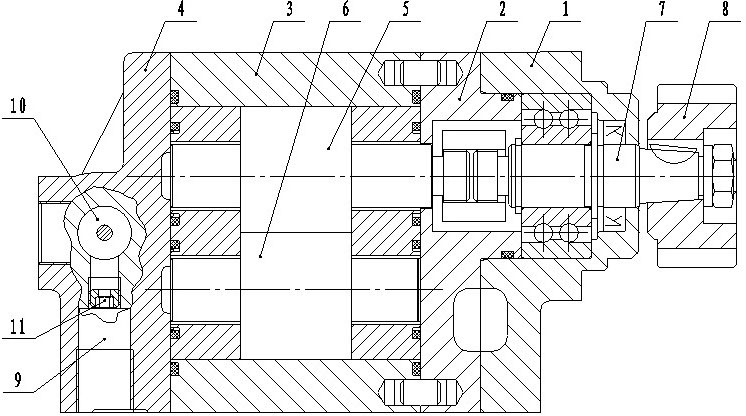

[0012] Such as figure 1 , figure 2 As shown, the steering gear pump of the present invention includes: a front cover 1, an intermediate body 2, a pump body 3, a rear cover 4, a driving gear 5, a driven gear 6, a transmission shaft 7 and a transmission gear 8, a rear cover 4, a pump body 3. The intermediate body 2 and the front cover 1 are installed together in turn, the driving gear 5 and the driven gear 6 are installed inside the pump body 3 and the driving gear 5 is meshed with the driven gear 6, and the transmission shaft 7 is sleeved in the front cover 1 through the bearing , one end of the transmission shaft 7 is connected with the central axis of the driving gear 5, and the other end of the transmission shaft 7 passes through the front cover 1 and is connected with the transmission gear 8; There is a slide valve 10, a throttling valve 11 is installed through threads in the oil outlet 9, and an oil return port 12 is also arranged on the back cover 4, and the oil return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com