Heat-dissipating disk for LED (light-emitting diode) lamps

A technology of LED lamps and heat sinks, applied in the cooling/heating devices of lighting devices, lighting and heating equipment, components of lighting devices, etc., can solve the problem of not having internal heat dissipation performance, and achieve long service life and small size , improve the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

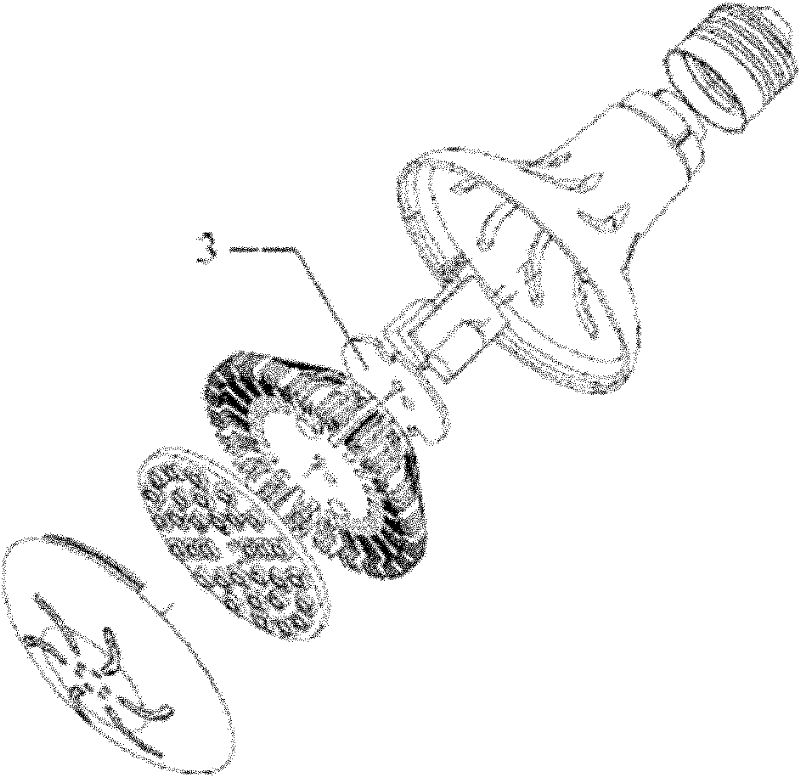

[0019] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings. The above and other objects, features and advantages of the present invention will be apparent to those skilled in the art from the detailed description of the present invention.

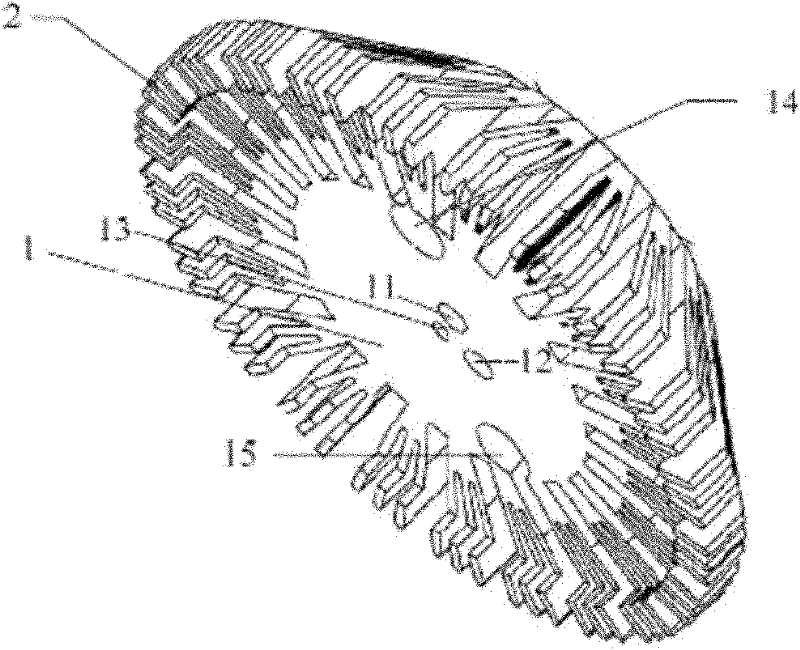

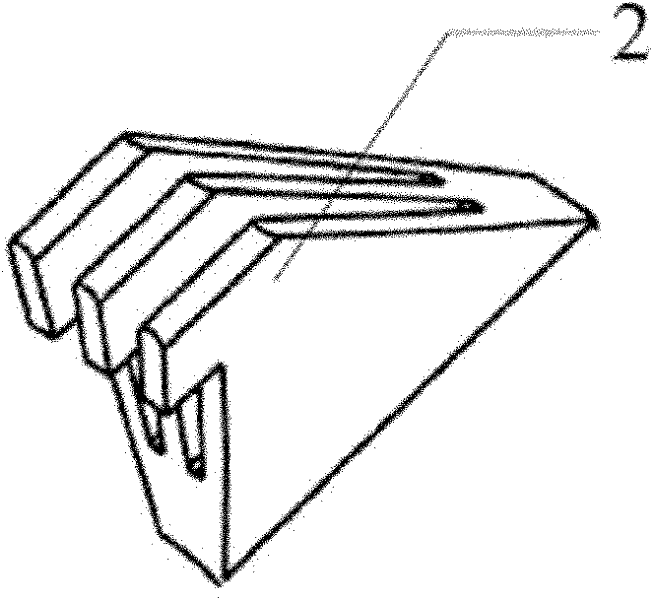

[0020] figure 1 Shown is a structural diagram of a heat dissipation disk according to an embodiment of the present invention, including a base 1 and a plurality of heat dissipation fins 2 . The base is located in the center and plays the role of supporting the cooling fins. The shape of the base can be cylindrical, square, conical, prismatic, or other irregular three-dimensional shapes, and the present invention is not limited thereto. Preferably, the base is a cylindrical structure, so that the cooling fins 2 can be formed more regularly on its outer periphery.

[0021] The base 1 is provided with a first hole 11 and a second hole 12 penetrating up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com