Manufacturing method of green pellets

A manufacturing method and technology of green pellets, applied in the field of green pellet manufacturing, can solve problems such as difficult dehydration of green pellets, easy cracking, and poor quality of green pellets, so as to reduce the probability of cracking, improve quality, and improve thermal performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

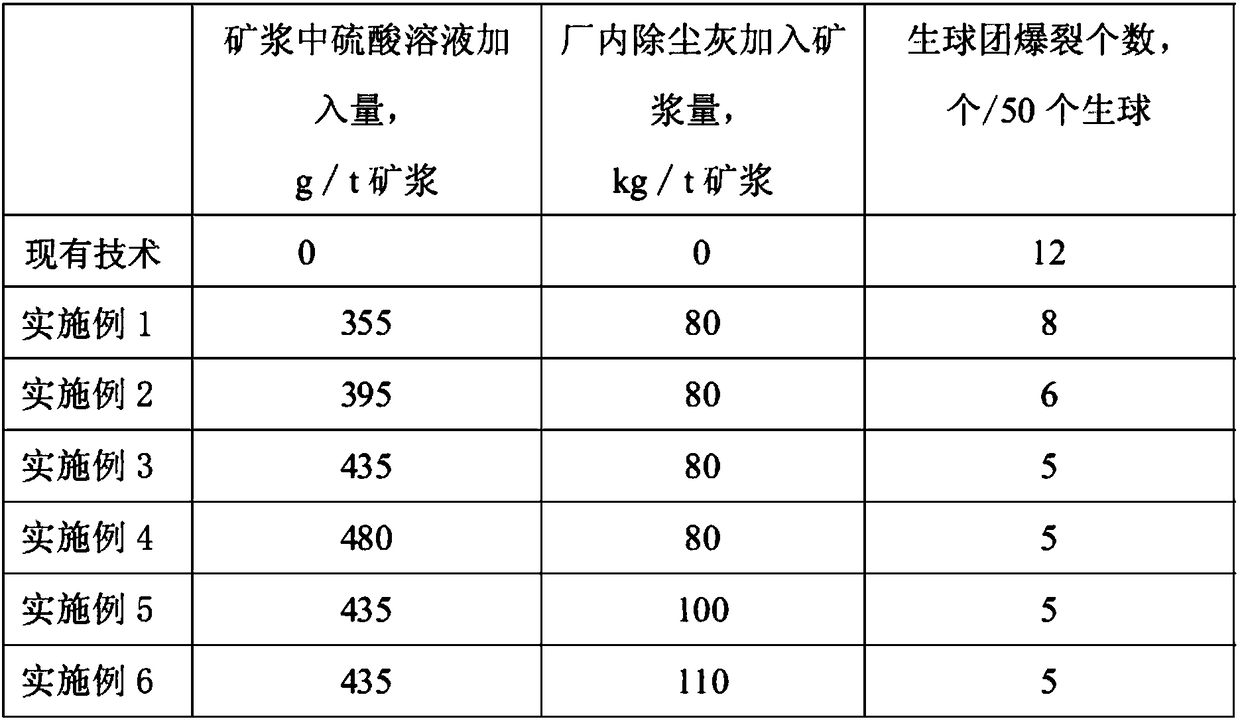

Embodiment 1

[0047] In this embodiment, in the filtering step after the beneficiation step, 30% (by mass percentage) sulfuric acid solution is added to the pulp, and at the same time or later, the dedusting ash in the plant is also "in advance" added to the pulp. The "advance" here is relative to the prior art method described in the background art section, in which the dedusting ash in the plant is added during "pelletizing".

[0048] Specific steps are as follows:

[0049] (1) Sulfuric acid solution is provided: the concentrated sulfuric acid is prepared into a 30% (by mass percentage) sulfuric acid solution.

[0050] (2) Add sulfuric acid solution into the pulp: add 30% sulfuric acid solution into the pulp, the consumption of sulfuric acid solution is 355g / t pulp.

[0051] (3) Add dust removal ash in the factory to the pulp: the amount of dust removal dust in the factory is 80kg / t pulp.

[0052] (4) Filtrating the pulp to obtain iron ore concentrate powder.

[0053] (5) Pelletizing w...

Embodiment 2

[0065] In this embodiment, in the filtering step after the beneficiation step, 30% (by mass percentage) sulfuric acid solution is added to the pulp, and at the same time, the dedusting ash in the plant is also added to the pulp in advance.

[0066] Specific steps are as follows:

[0067] (1) Sulfuric acid solution is provided: the concentrated sulfuric acid is prepared into a 30% (by mass percentage) sulfuric acid solution.

[0068] (2) Add sulfuric acid solution to the pulp: add 30% sulfuric acid solution into the pulp, the consumption of sulfuric acid solution is 395g / t pulp.

[0069] (3) Add dust removal ash in the factory to the pulp: the amount of dust removal dust in the factory is 80kg / t pulp.

[0070] (4) Filtrating the pulp to obtain iron ore concentrate powder.

[0071] (5) Pelletizing with iron concentrate powder to obtain green pellets.

[0072] The iron concentrate powder and bentonite are compounded according to the following weight percentages, and the specif...

Embodiment 3

[0083] In this embodiment, in the filtering step after the beneficiation step, 30% (by mass percentage) sulfuric acid solution is added to the pulp, and at the same time, the dedusting ash in the plant is also added to the pulp in advance.

[0084] Specific steps are as follows:

[0085] (1) Sulfuric acid solution is provided: the concentrated sulfuric acid is prepared into a 30% (by mass percentage) sulfuric acid solution.

[0086] (2) Add sulfuric acid solution into the pulp: add 30% sulfuric acid solution into the pulp, the consumption of sulfuric acid solution is 435g / t pulp.

[0087] (3) Add dust removal ash in the factory to the pulp: the amount of dust removal dust in the factory is 80kg / t pulp.

[0088] (4) Filtrating the pulp to obtain iron ore concentrate powder.

[0089] (5) Pelletizing with iron concentrate powder to obtain green pellets.

[0090] Carry out batching with iron ore concentrate powder and bentonite according to the following weight percentage, conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com