Producing process for novel integrated heat insulating window used for breeding industry

A production process and aquaculture technology, applied in windows/doors, door/window applications, soundproof doors/windows, etc., can solve the problems affecting color steel sandwich panel heat insulation, heat preservation, sound insulation, increasing building footprint and Use cost, heat insulation performance is not very ideal and other problems, to achieve the effect of stability and not easy to fall off, smooth edges and sides, good deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

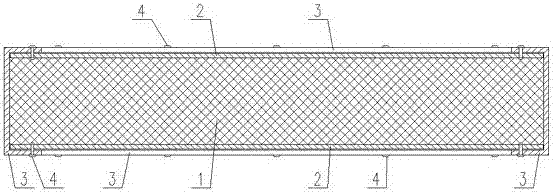

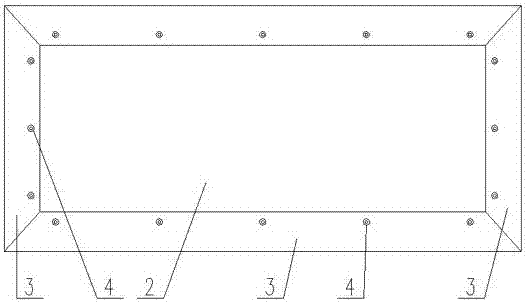

Image

Examples

Embodiment 1

[0015] Embodiment 1: The production process of the integrated thermal insulation window for the new type of breeding industry, its production process is as follows:

[0016] a. White material premixing: Take 95 kg of polyether polyol, 32 kg of blowing agent, 3 kg of catalyst, 2 kg of foam stabilizer and 1 kg of water according to the following ingredients and weight ratio, and mix them well to make white material, the polyether polyol is polytetrahydrofuran ether glycol, the foaming agent is fluorodichloroethane, the catalyst is triethylenediamine, and the foam stabilizer is silicone oil, and the foam stabilizer can be Select CGY-1 silicone oil produced by Yangzhou Chenhua New Material Co., Ltd.;

[0017] b. Pouring and foaming: Preheat the temperature of the mold and keep it at 42°C. According to the specifications and dimensions of the new integrated thermal insulation window for aquaculture, use 8 seconds to fully mix the black material and white material and stir evenly, t...

Embodiment 2

[0020] Embodiment 2: The production process of the integrated thermal insulation window for the new type of breeding industry, its production process is as follows:

[0021] a. White material premixing: Take 100 kg of polyether polyol, 35 kg of foaming agent, 4 kg of catalyst, 3 kg of foam stabilizer and 2 kg of water according to the following ingredients and weight ratio, and mix them well to make white material, the polyether polyol is polytetrahydrofuran ether glycol, the foaming agent is fluorodichloroethane, the catalyst is triethylenediamine, and the foam stabilizer is silicone oil, and the foam stabilizer can be Select CGY-1 silicone oil produced by Yangzhou Chenhua New Material Co., Ltd.;

[0022] b. Pouring and foaming: Preheat the temperature of the mold and keep it at 45°C. According to the specifications and dimensions of the new integrated thermal insulation window for aquaculture, use 10 seconds to fully mix the black material and white material and stir evenly,...

Embodiment 3

[0025] Embodiment 3: The production process of the integrated thermal insulation window for the new type of breeding industry, its production process is as follows:

[0026] a. White material premixing: Take 105 kg of polyether polyol, 38 kg of blowing agent, 5 kg of catalyst, 4 kg of foam stabilizer and 3 kg of water according to the following ingredients and weight ratio, and mix them well to make white material, the polyether polyol is polytetrahydrofuran ether glycol, the foaming agent is fluorodichloroethane, the catalyst is triethylenediamine, and the foam stabilizer is silicone oil, and the foam stabilizer can be Select CGY-1 silicone oil produced by Yangzhou Chenhua New Material Co., Ltd.;

[0027] b. Pouring and foaming: Preheat the temperature of the mold and keep it at 48°C. According to the specifications and dimensions of the new integrated thermal insulation window for aquaculture, use 12 seconds to fully mix the black material and white material and stir evenly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com