Method for measuring directional blasting collapse time of chimney

A technology of directional blasting and time measurement, applied in vibration measurement, measurement device, vibration measurement in solids, etc., can solve the problem of large time error of chimney collapse, and achieve the effect of simple operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

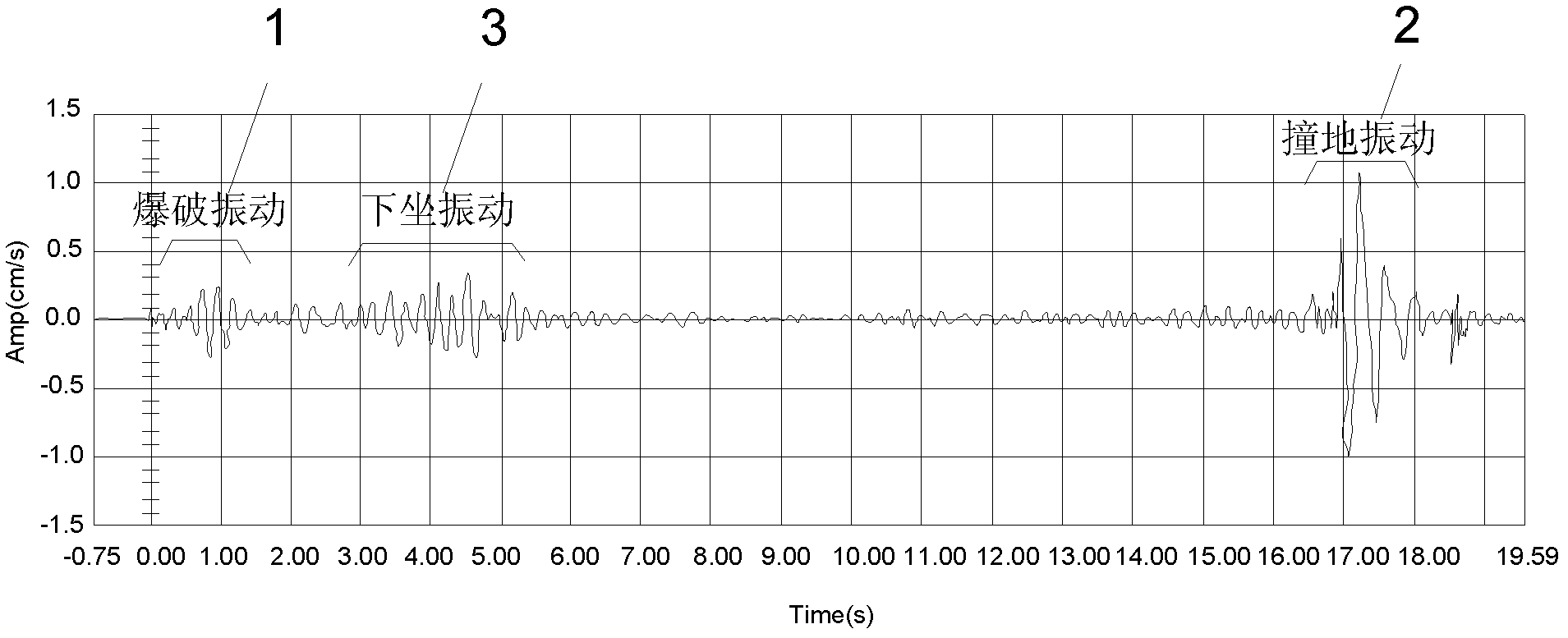

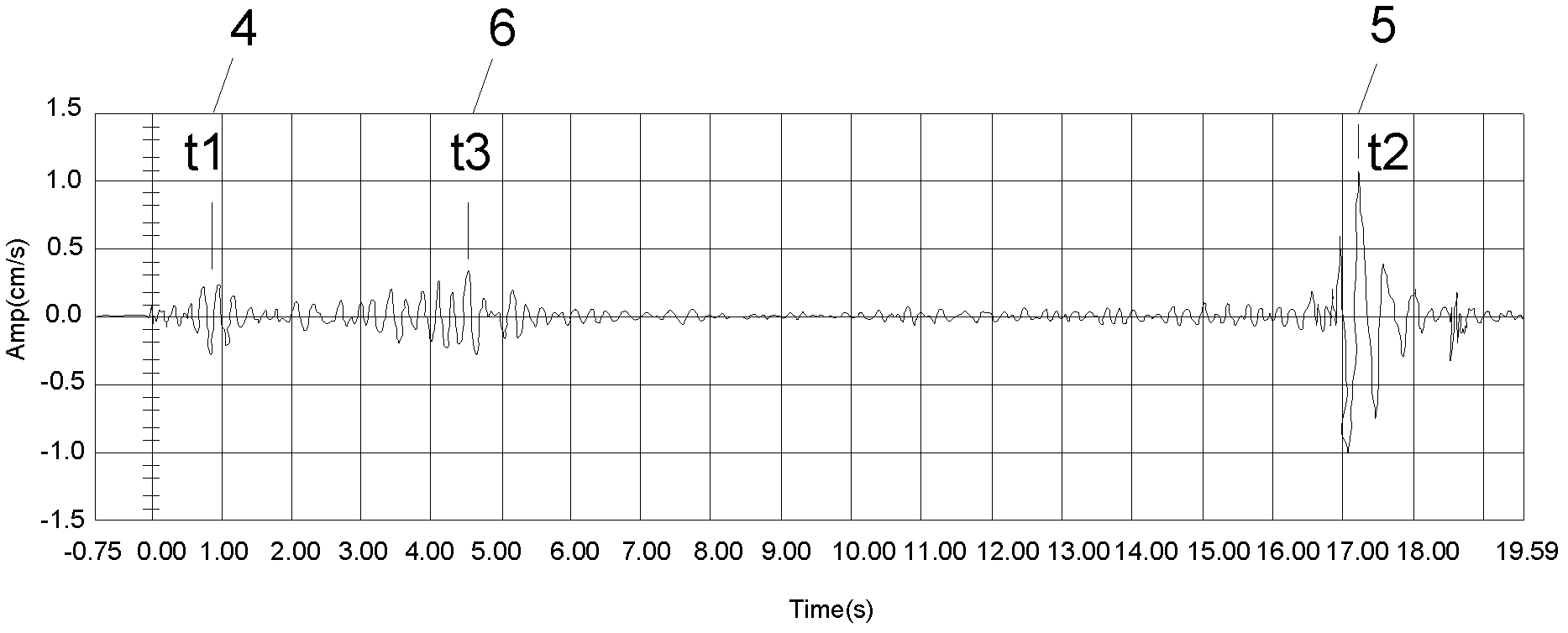

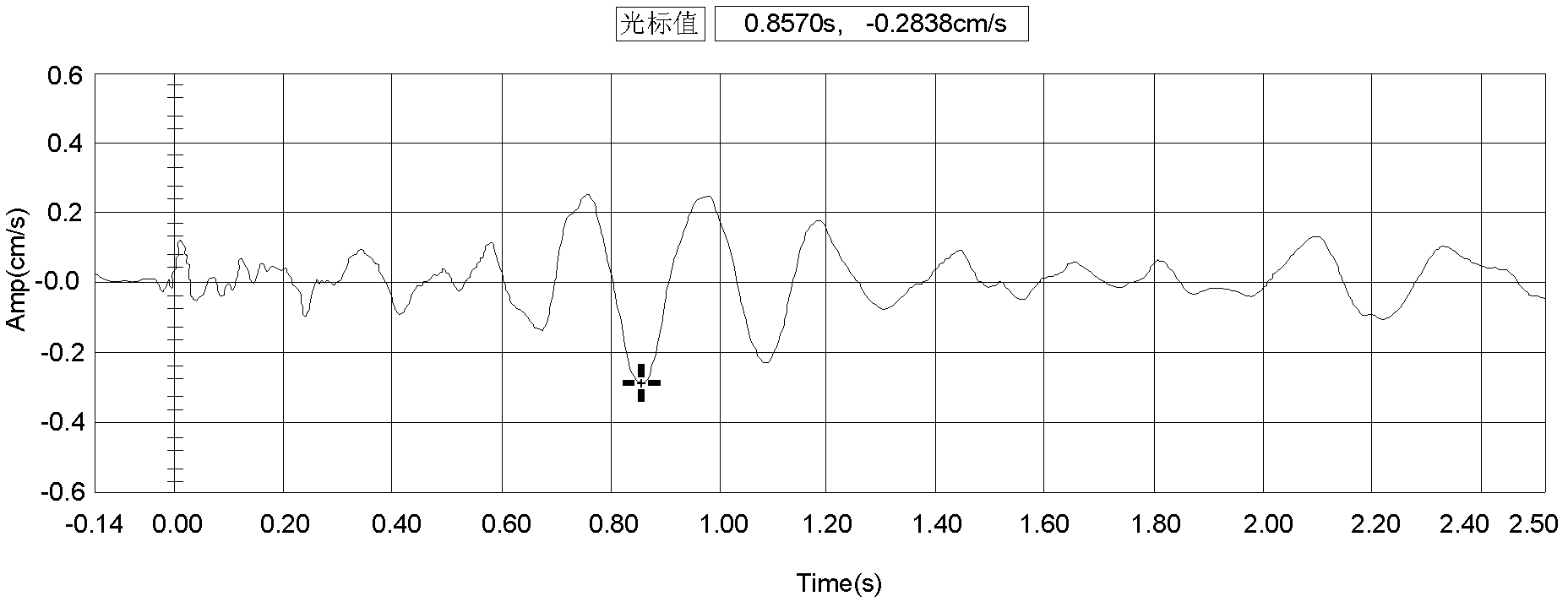

[0018] In the monitoring process of a large number of chimney blasting vibrations, it is found that the collapse vibration of chimneys has the following rules: During the entire collapse process of the chimney from detonation, sitting down to hitting the ground, the vibration speed of hitting the ground is the largest, followed by the sitting down vibration, and the minimum is the blasting vibration; In the direction of chimney collapse, the closer the distance to the top of the chimney is, the greater the impact vibration will be; in addition, the chimney collapse time t(s) has a greater relationship with the chimney height h(m), which is approximately equal to 10% of the chimney height One, namely: t≈h / 10(s). Therefore, in order to accurately measure the entire collapse vibration waveform of the chimney, it is necessary to pay attention to the reasonable arrangement of the vibration measurement points, the reasonable setting of the parameters of the vibration measurement inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com