Plugging photoelectric composite connector

A technology for optoelectronic composite and optoelectronic composite cables, which is applied in the direction of connection, coupling of optical waveguides, and two-component connection devices, etc., can solve the problems of difficult construction, maintenance and replacement, many joints, and increased cost of connector sealing and connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

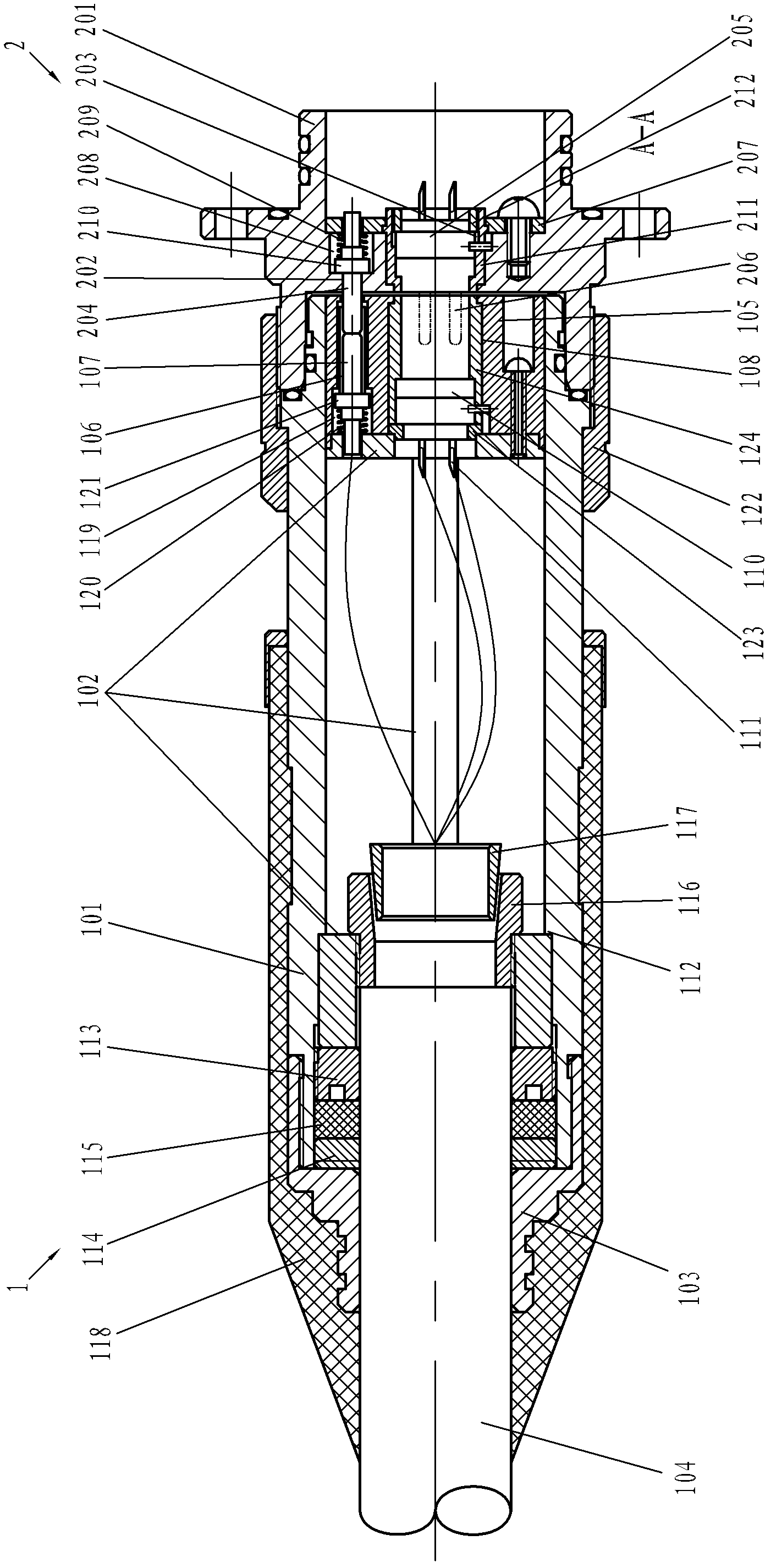

[0022] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

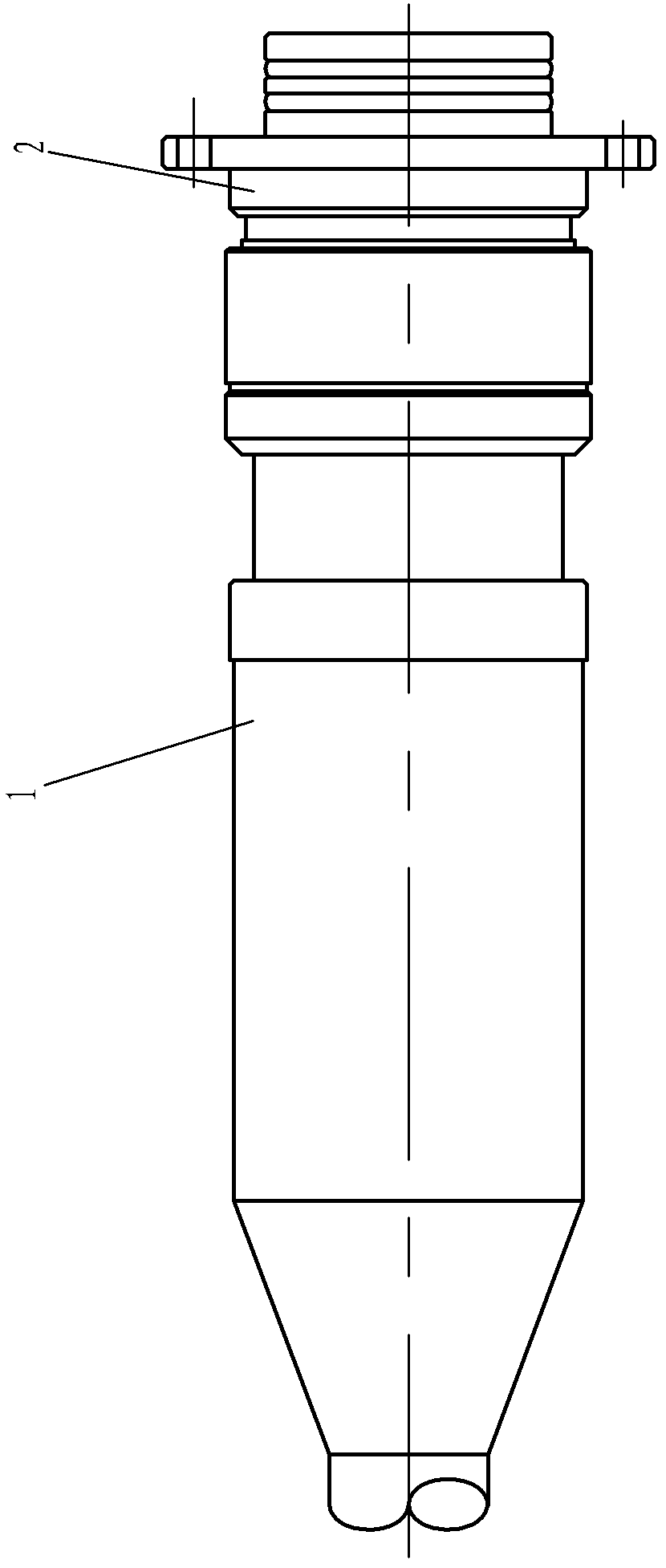

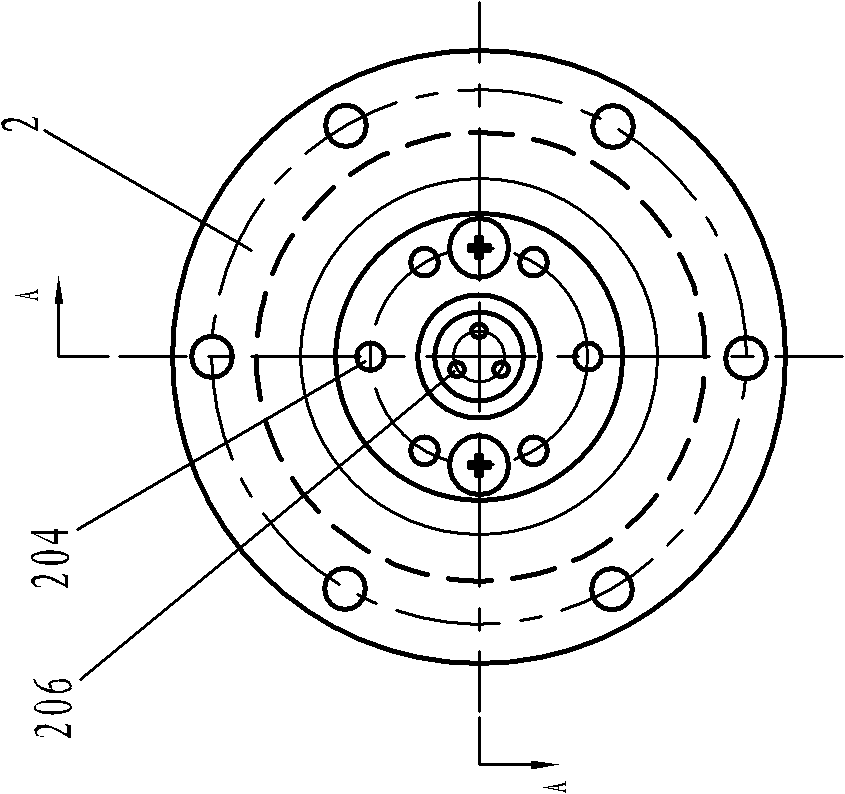

[0023] refer to Figure 1 to Figure 3 As shown, the pluggable photoelectric composite connector of this embodiment includes a plug 1 and a socket 2 that is tightly connected to the thread, and the left side of the plug 1 is provided with an integrally formed vulcanized sealing layer 118, wherein:

[0024] Plug 1 comprises shell 101, and support 102 is installed in the shell 101 (as Figure 7 to Figure 9 As shown), the left end of the bracket 102 is equipped with a reserved photoelectric composite cable 104, and the left end of the casing 101 is threadedly connected with a tail sleeve 103, and the left end of the reserved photoelectric composite cable 104 protrudes from the left end of the tail sleeve 102, and is connected to the tail sleeve 102. The joint of the left end of the sleeve 102 is sealed, and the left side of the tube shell 101 is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com