Display substrate and manufacturing method thereof

A production method and display technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of inaccurate alignment, lower yield rate of liquid crystal panels, etc., and achieve the effect of solving heavy industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following will clearly illustrate the spirit of the present invention with drawings and detailed descriptions. Anyone with ordinary knowledge in the relevant technical field can change and modify the technology taught by the present invention after understanding the preferred embodiments of the present invention. It does not depart from the spirit and scope of the present invention.

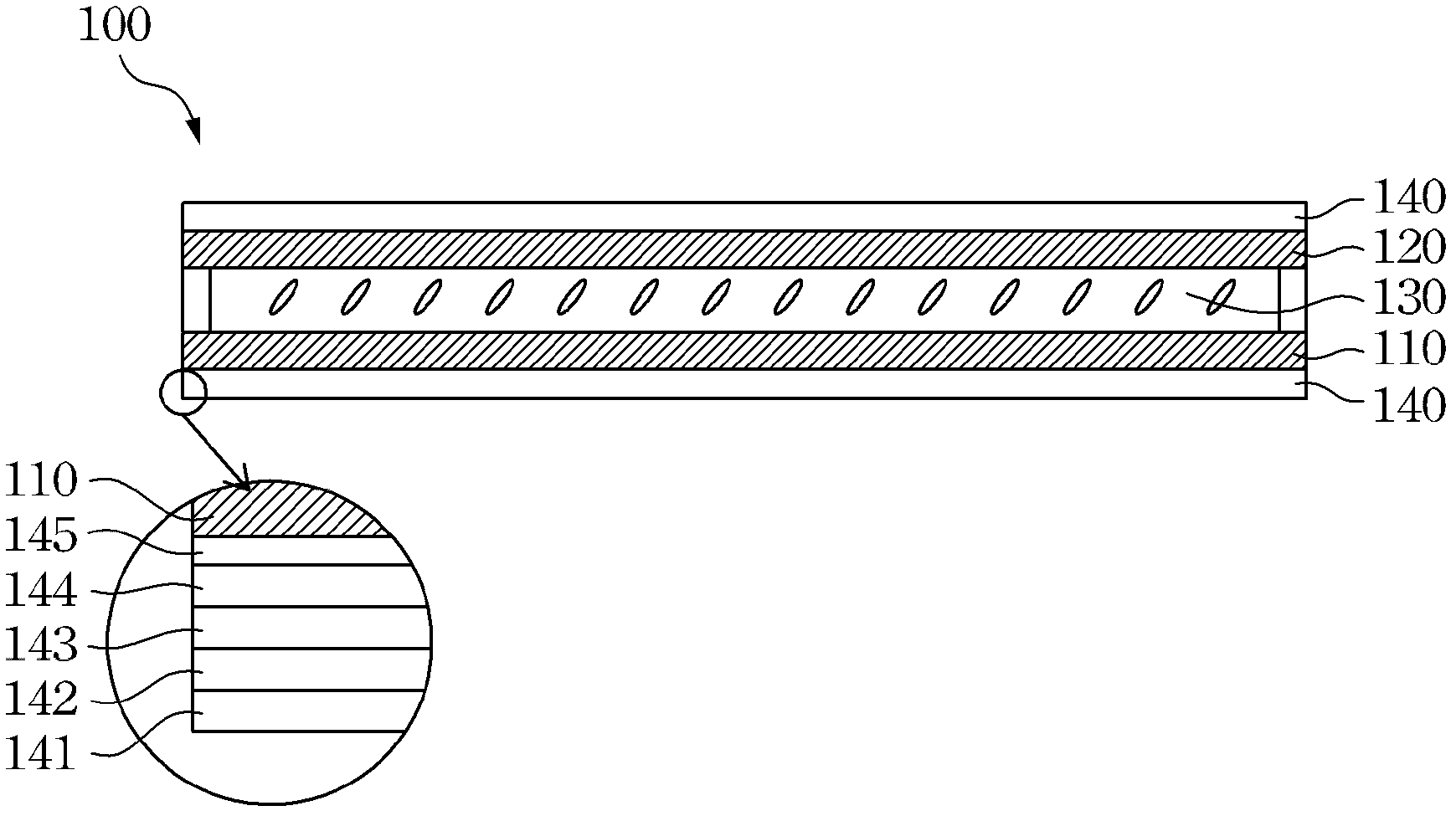

[0042] Reference figure 1 , Which shows a cross-sectional view of a conventional LCD panel. The conventional liquid crystal panel 100 includes a thin film transistor substrate 110, a color filter 120, a liquid crystal layer 130 sandwiched between the color filter 120 and the thin film transistor substrate 110, and are attached to the thin film transistor substrate 110 and the color filter respectively. Two polarizers 140 on the light sheet 120. The polarizer 140 includes a surface protective film 141, a first protective layer 142, a polarizing base 143, a second protective layer 144, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com