Composite glove and production method thereof

A technology of gloves and composite materials, applied in the direction of gloves, chemical instruments and methods, synthetic resin layered products, etc., to achieve the effect of good comfort and good liquid barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

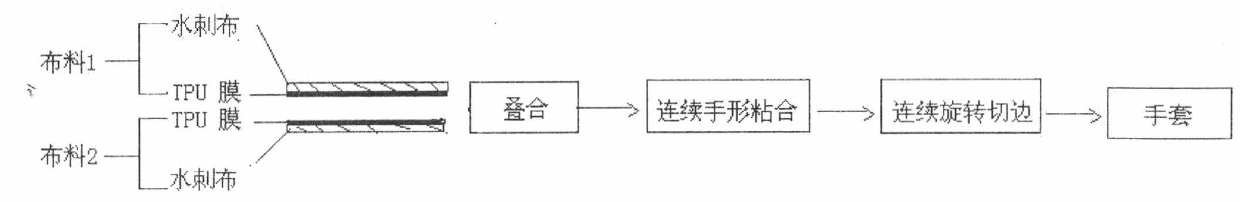

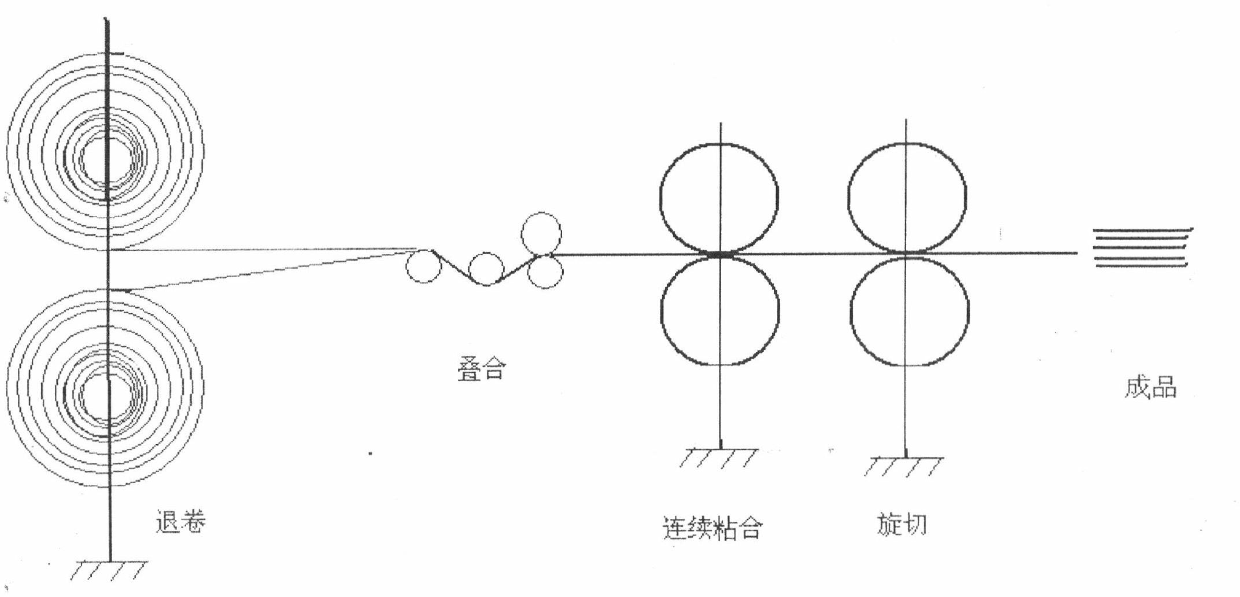

[0020] Glove A is a product implemented in the present invention. The product is composed of basic composite materials. The outer layer of the composite material is a TPU plastic film, and the inner layer is a spunlace nonwoven. The TPU film is a breathable and moisture-permeable film with a thickness of 0.03mm; the spunlace nonwoven fabric is made of 70% PET / 30% R, and the weight is 35GSM. The two materials are combined in-line to form the base composite. The composite materials are compounded according to the hand mold through a continuous ultrasonic bonding device. After another rotary cutting tool, the product is formed

[0021] Comparative product glove B is formed by thermocompression bonding of plastic film PE, and the thickness of the film is 0.05mm.

[0022] Glove C, a comparative product, is made of needle-punched non-woven fabric by thermocompression bonding. The raw material is 100% polyester, and the weight is 70GSM.

[0023] Comfort Permeability Weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com