Method for preparing braided tube/polymer composite hollow fibrous membrane by thermal induction method

A technology of braided tube and polymer, which is applied in the field of braided tube/polymer composite hollow fiber membrane prepared by thermal induction method, can solve the problems of easy pollution, easy detachment of support layer and coating layer, etc., so as to prolong service life and improve performance Broad, reduced binding resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 13wt% polyvinylidene fluoride, 2wt% cellulose acetate, 77wt% dimethylacetamide, 5wt% polyvinylpyrrolidone, 3wt% LiCl were stirred and dissolved at 60°C for 12h, and left standing at 60°C for 12h to obtain Homogeneous casting film①. Melt blend 13wt% polyvinylidene fluoride, 80wt% triethyl phosphate, 5wt% polyvinylpyrrolidone, and 2wt% LiCl in a high-temperature container. The temperature is raised to 100°C and stirred for 24h, and it is left standing at 100°C for 12h. A homogeneous casting liquid ② is obtained.

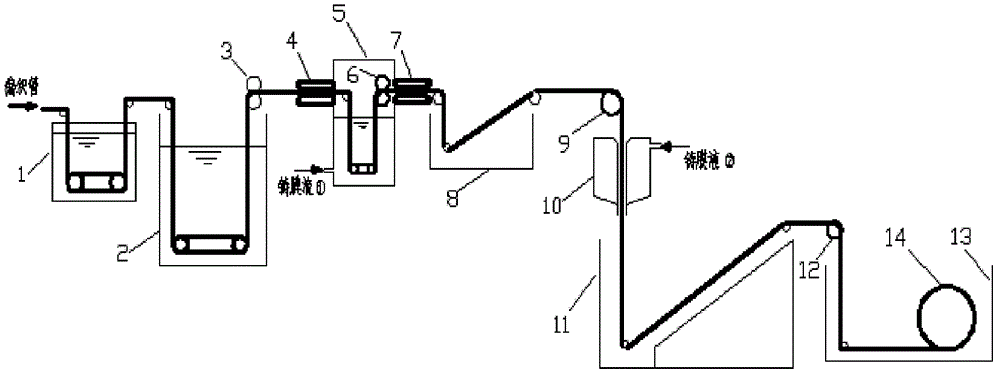

[0045] Such as figure 1 As shown, the PET fiber braided tube (24-spindle yarn, outer diameter 1.2mm, density 40 mesh) was immersed in the decontamination tank 1 filled with boiling NaOH (10wt%) solution for 20 minutes, and then deionized at room temperature Wash with water; after washing, immerse it in the modification tank 2 containing the modification solution (comprising of trifluoroethyl methacrylate / ethyl acetate according to the volume ratio of 1:5) for 20 m...

Embodiment 2

[0053] Combine 10wt% polyvinylidene fluoride, 80wt% dimethylacetamide, 5wt% polyvinyl alcohol, 5wt% SiO 2 Stir and dissolve at 80°C for 24h, and stand still at 80°C for 24h to defoam to obtain a homogeneous casting solution①. Combine 12wt% polyvinylidene fluoride, 8wt% polyethersulfone, 70wt% triethyl phosphate, 6wt% polyvinylpyrrolidone, 2wt% FeCl 3 , 2wt% LiCl was melted and blended in a high temperature resistant container, heated to 140°C and stirred for 24h, and left standing at 140°C for 24h to defoam to obtain a homogeneous casting liquid ②.

[0054] The PET fiber braided tube (24-spindle yarn, outer diameter 1.2mm, density 40 mesh) is immersed in a boiling NaOH (15wt%) solution for 10 minutes, and then washed with deionized water at room temperature; after washing, it is immersed in the modified In the liquid (hexafluorobutyl acrylate + perfluoroheptyl acrylate (1:1) / ethyl acetate in a volume ratio of 1:10) for 15 minutes, then rolling under a pressure of 0.8 MPa at a roll...

Embodiment 3

[0058] 5wt% polysulfone, 85wt% dimethylacetamide, 4wt% polyvinylpyrrolidone, 6wt% LiCl were stirred and dissolved at 40°C for 36h, and allowed to stand at 40°C for 24h to defoam to obtain a homogeneous casting solution①. 4wt% polyvinylidene fluoride, 6wt% polymethyl methacrylate, 80wt% dioctyl phthalate, 6wt% FeCl 3 , 2wt% polyvinylpyrrolidone and 2wt% LiCl were melt blended in a high temperature container, heated to 170°C and stirred for 24h, and left standing at 170°C for 48h to defoam to obtain a homogeneous casting liquid ②.

[0059] Immerse the PET fiber braided tube (18 spindles of yarn, outer diameter of 3.0mm, density of 100 mesh) in boiling NaOH (5wt%) solution for 20 minutes, and then wash with deionized water at room temperature; after washing, immerse it in the modified In a hot liquid (dodecafluoroheptyl methacrylate / butyl acetate in a volume ratio of 1:20) for 30 minutes, then rolling at a pressure of 0.6 MPa, a rolling speed of 7 m / min, and a temperature of 170 ℃ af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com