Method for preparing double-surface composite flat membrane

A surface composite and flat membrane technology, applied in the field of membrane separation, can solve the problems of not considering the bonding force between the support layer and the coating layer, not considering the anti-pollution performance of non-woven fabrics, and not considering the influence of non-woven fabric membrane filtration performance, etc. , to achieve the effect of improving anti-pollution performance, improving hydrophilicity, and improving interception capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Stir and dissolve 15wt% polyvinylidene fluoride, 76wt% dimethylacetamide, 6wt% polyvinylpyrrolidone, and 3wt% LiCl at 60°C for 24 hours, and stand at 60°C for 12 hours to obtain the desired homogeneous cast film liquid, spare;

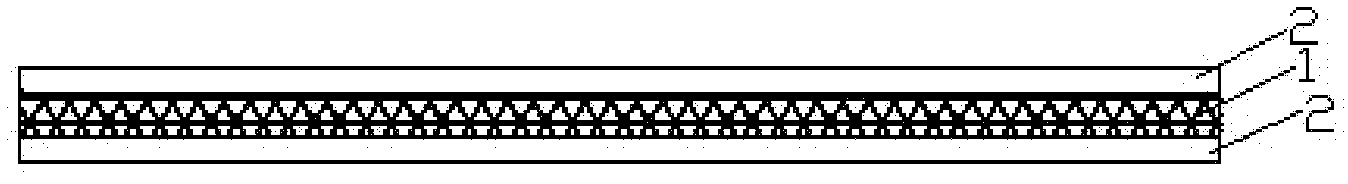

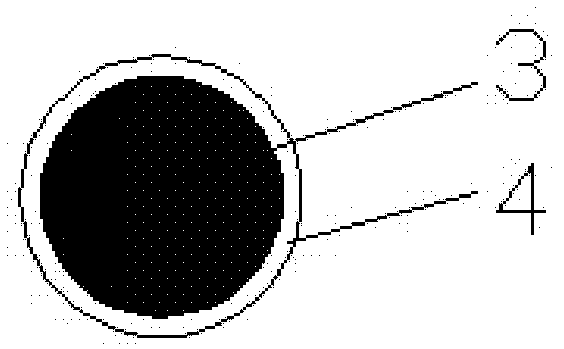

[0030] Clean the polypropylene non-woven fabric with a cleaning agent (the non-woven fabric has a grammage of 15g / m 2 , a polypropylene spun-bonded non-woven fabric with a thickness of 0.15mm), then soak it in a boiled 10wt% NaOH solution for 10min, rinse it with tap water; soak the above-mentioned non-woven fabric in 10% H by volume at normal temperature 2 o 2 After rinsing in tap water for 48 hours, dry it in an oven at 70°C; immerse the above-mentioned non-woven fabric that has been dried after removing spunbond dirt in dimethylacetamide, and wait until the non-woven fabric is completely wet Take it out and immerse it in the prepared casting solution for 10 minutes, then pull it out from the gap between two parallel cylindrical glass rods w...

Embodiment 2

[0034] Stir and dissolve 4wt% polyvinylidene fluoride, 86wt% dimethyl sulfoxide, 7wt% polyvinyl alcohol, and 3wt% LiCl at 20°C for 12 hours, and stand at 20°C for defoaming for 12 hours to obtain the desired homogeneous casting solution ,spare;

[0035] Clean the polypropylene non-woven fabric with a cleaning agent (the non-woven fabric has a grammage of 15g / m 2 , a polypropylene spun-bonded non-woven fabric with a thickness of 0.15mm), then soak it in a boiled 10wt% NaOH solution for 30min, rinse it with tap water; soak the above-mentioned non-woven fabric in 20% H by volume at normal temperature 2 o 2 After rinsing in tap water for 12 hours, dry it in an oven at 70°C; immerse the above-mentioned non-woven fabric that has been dried after removing spunbond dirt in dimethyl sulfoxide, and wait until the non-woven fabric is completely wet Take it out and immerse it in the prepared casting solution for 10 minutes, then pull it out from the gap between two parallel cylindrical ...

Embodiment 3

[0038] Stir and dissolve 10wt% polyvinylidene fluoride, 5wt% cellulose acetate, 75wt% N-methylpyrrolidone, 7wt% polyethylene glycol, 2wt% LiCl, and 1wt% SiO2 at 80°C for 36 hours, then let stand at 80°C to remove Soak for 24 hours to obtain the required homogeneous casting solution and set aside;

[0039] Clean the polypropylene non-woven fabric with a cleaning agent (the non-woven fabric has a grammage of 15g / m 2 , a polypropylene spun-bonded non-woven fabric with a thickness of 0.15 mm), then soak it in a boiled 10wt% NaOH solution for 20 min, and rinse it with tap water; soak the above-mentioned non-woven fabric in 30% H by volume at normal temperature 2 o2 After rinsing in tap water for 24 hours, dry it in an oven at 70°C; immerse the above-mentioned non-woven fabric that has been dried after removing spunbond dirt in N-methylpyrrolidone, and wait until the non-woven fabric is completely wet Take it out, soak it in the prepared casting solution for 20min, pull out the non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com