Special machine for correcting bend plates of crane booms and correcting method

A crane and bending plate technology, applied in the field of construction machinery, can solve the problems of low efficiency of manual hammering correction, unfavorable to realize standard operation and flow operation, limited position of hammering correction, etc., so as to improve work efficiency and correction quality, Achieve the effect of standard operation and streamlined operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

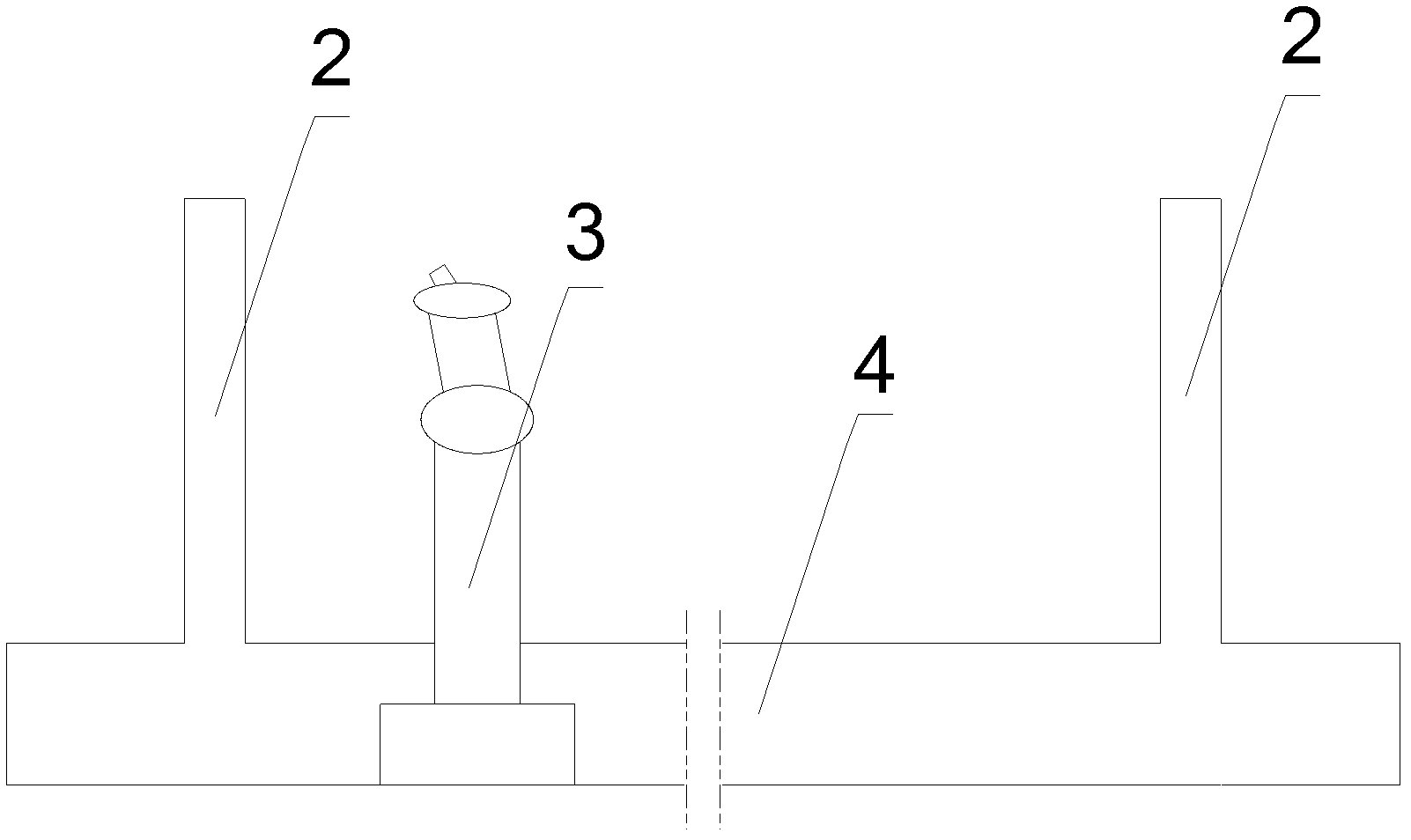

[0038] refer to figure 1 with figure 2 .

[0039] This embodiment includes a platform 4, a lifting and turning machine 2 and a hammering device 3; wherein, the lifting and turning machine 2 is used to clamp the bent plate of the crane arm, and realize the lifting and turning of the bent plate; the hammering device 3 is slidably connected The first guide rail 8 is used to hammer the bent plate of the boom of the crane; the platform 4 is a platform with a detection reference, which is used to provide a calibration reference for the hammering device 3 .

[0040] In addition, it should be noted that the liftable turning machine 2 may not be connected with the platform 4 . If the two are connected together, the platform where the liftable turning machine 2 is placed must have a step surface to ensure that when the curved plate is lowered by the lifting turning machine 2, the chain of the lifting turning machine 2 can fall below the platform 4, ensuring The bent plate can be pla...

no. 2 example

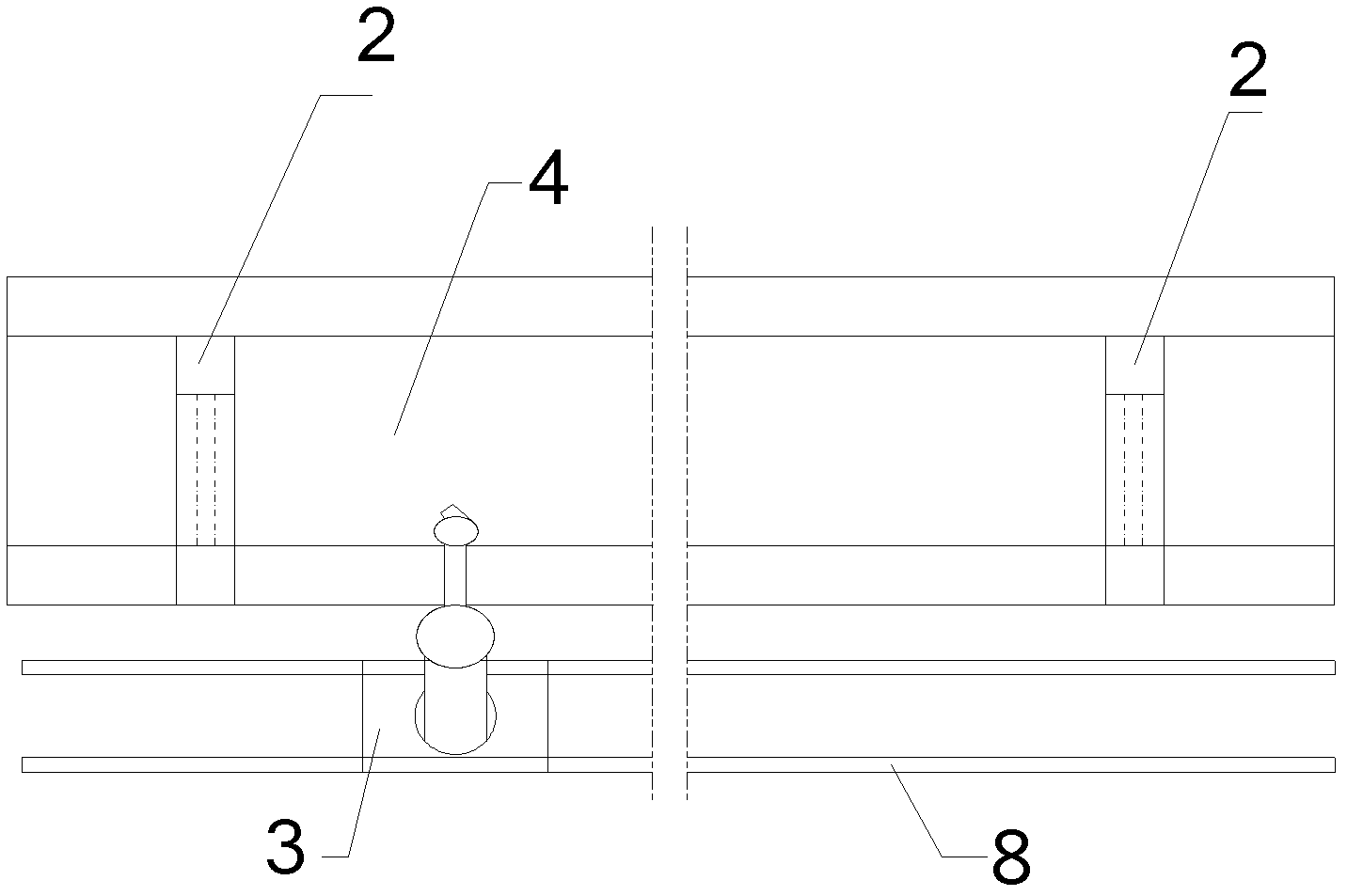

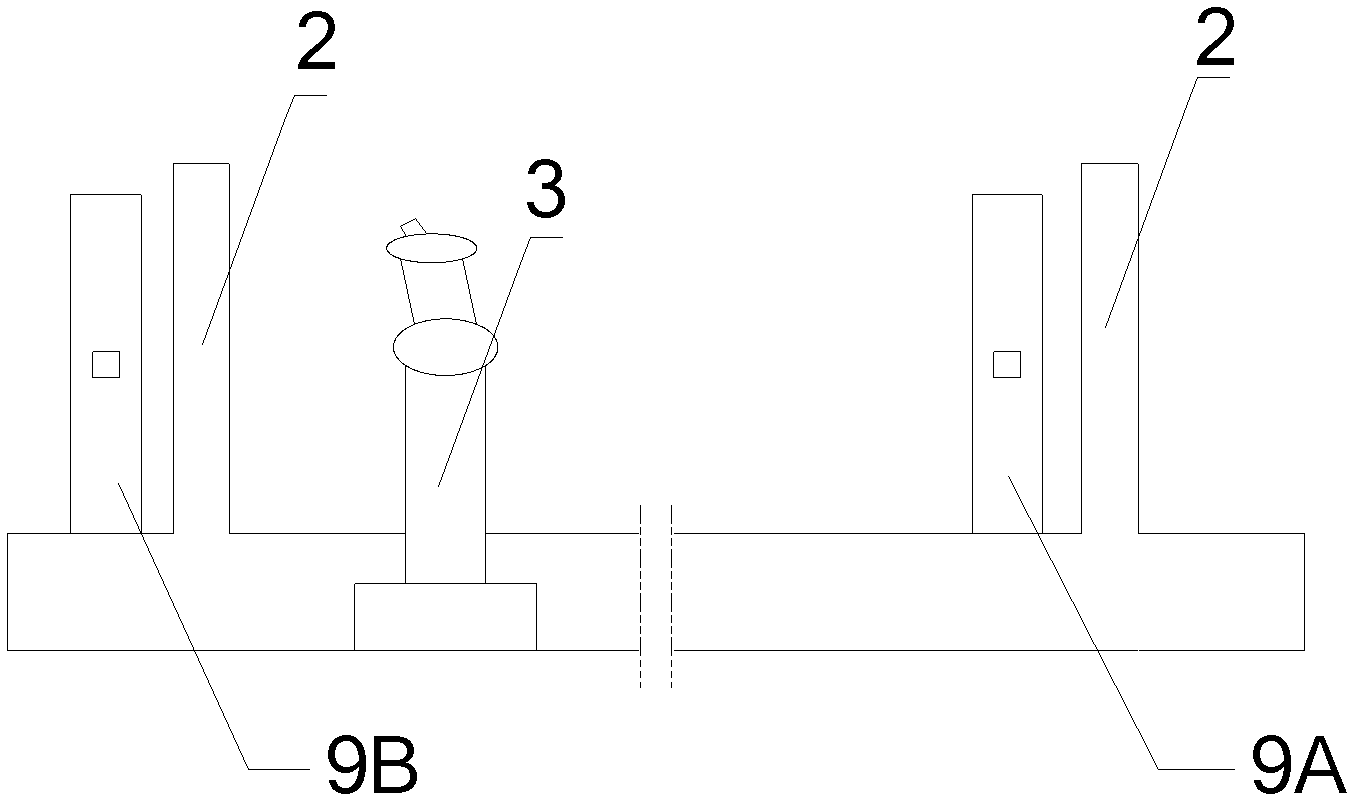

[0043] refer to image 3 with Figure 4 .

[0044] The special machine for correcting the bent plate of the crane arm in this embodiment includes: this embodiment includes a platform 4, a liftable turning machine 2 and a hammering device 3; Lifting and flipping of the board; the hammering device 3 is slidably connected to the first guide rail 8 for hammering the bent plate of the crane arm;

[0045] Moreover, different from the first embodiment, the calibration plane also includes a first detection device 9A and a second detection device 9B, and these two detection devices are slidably connected to the platform 4 through the second guide rail 11 .

[0046] Since the platform in this embodiment is a platform with a detection reference, and there are two detection devices connected to the platform, the height and straightness of the bent plate can be automatically detected by the detection device, avoiding the possibility of being caused by manual experience. The defects of l...

no. 3 example

[0048] refer to Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 .

[0049] The special machine for correcting the bent plate of the crane boom in this embodiment includes: this embodiment includes a platform 4, a liftable turning machine 2, a hammering device 3, a first detection device 9A, and a second detection device 9B; wherein, the liftable turning machine 2 is used It is used to clamp the bent plate of the crane arm, and realize the lifting and turning of the bent plate; the hammering device 3 is slidably connected to the first guide rail 8, and is used to hammer the bent plate of the crane arm; the platform 4 is a platform with a detection reference , used to provide a calibration reference for the hammering device 3 . The first detection device 9A and the second detection device 9B are slidably connected to the platform 4 through the second guide rail 11 .

[0050] In addition, different from the above two embodiments, the surface of the platform 4 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com