Die-casting die structure with combination of multiple angle pins and loose core for connecting pipes

A die-casting mold and connecting pipe technology, applied in the field of die-casting molds, can solve problems such as low production efficiency, surface pores, mechanical strength and low production efficiency, and achieve the effects of improving production efficiency, saving costs, and improving the degree of production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

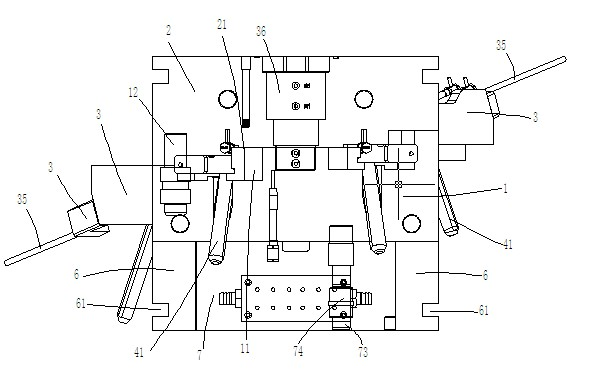

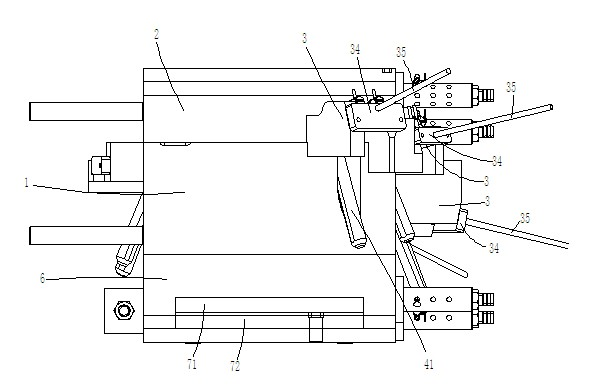

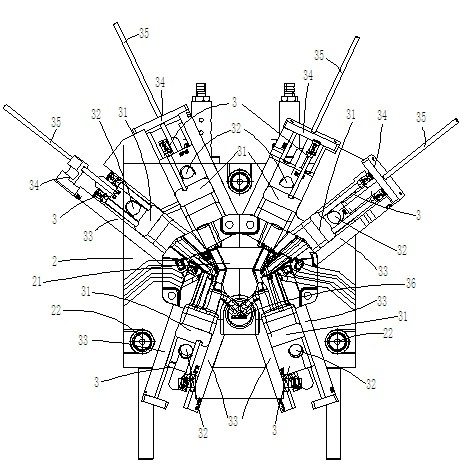

[0021] Such as Figure 1 to Figure 4 As shown, the icon numbers are as follows: lower mold frame 1, lower mold core 11, guide column 12, upper mold frame 2, upper mold core 21, guide hole 22, tailstock unit 3, slider 31, oblique pin hole 32, Bead 33, guide seat 34, guide rod 35, barrel 36, tailstock drive unit 4, oblique pin 41, locking block 42, lower mold frame slider cavity 43, feed port 5, side mold foot 6, notch Fixing groove 61, middle die foot 7, upper top plate 71, lower top plate 72, top plate guide post 73, top plate guide post cover 74.

[0022] In the embodiment of the present invention, the die-casting mold structure of connecting pipe multi-slant pin core-pulling combination, the die-casting mold includes a lower mold frame 1 and an upper mold frame 2 that are fitted on the die-casting machine and can be mated, and the lower mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com