Electric shock prevention device for electric welding machine

An anti-electric shock and electric welding machine technology, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problem of death by electric shock and achieve rapid tripping and excellent anti-electric shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] An electric shock protection device for an electric welding machine of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

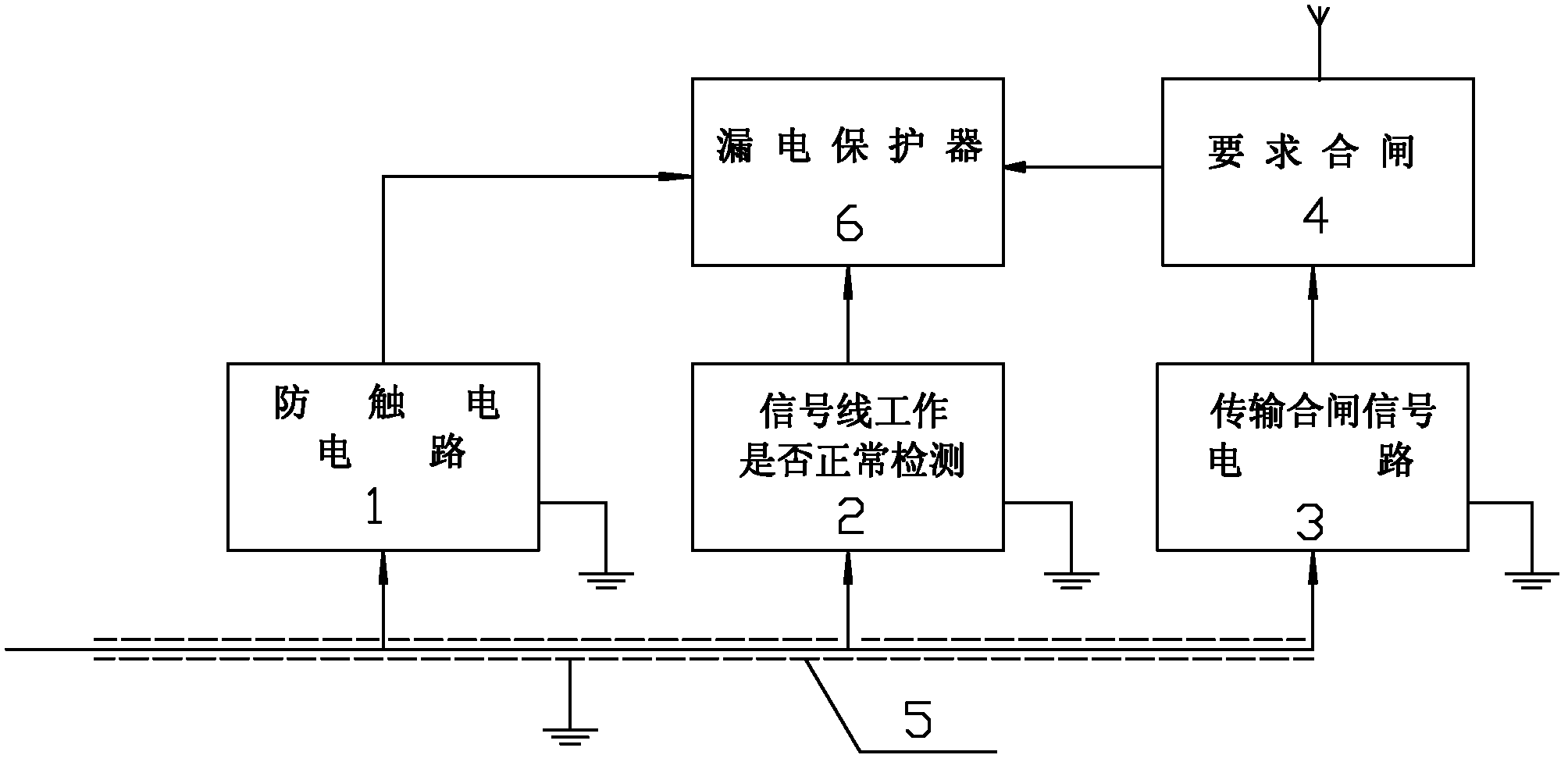

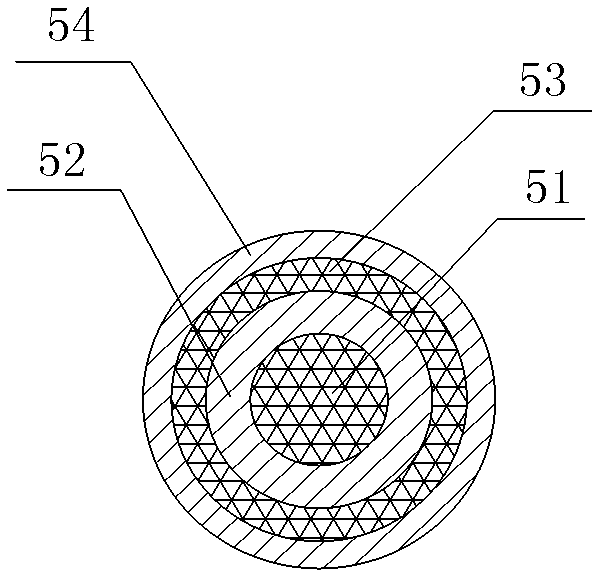

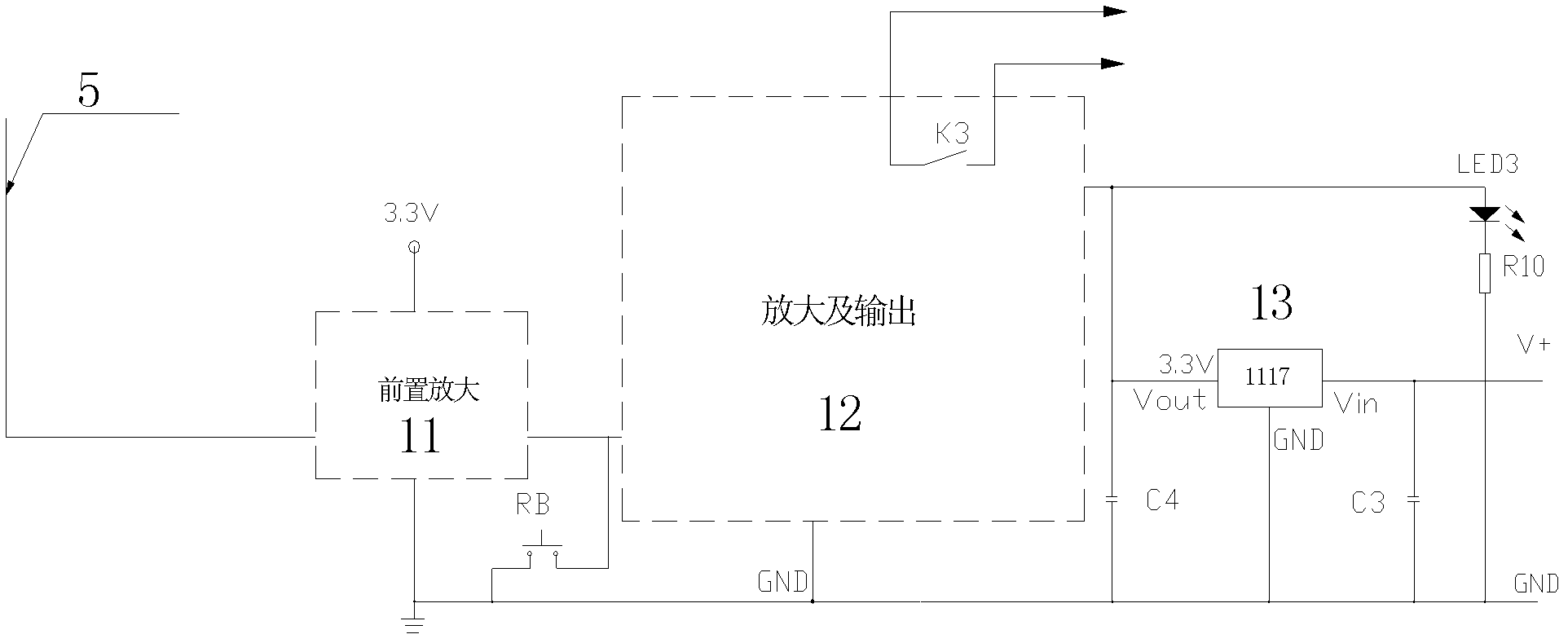

[0042] Electric welding machine anti-shock device of the present invention, as figure 1 As shown, use a simple ring signal line (the signal line is placed on the finger, or held in the palm of the hand; or the signal line is connected to a conductive object, and the conductive object is in contact with the hand or wrist, ankle, etc.), and the welding The weak electric induction signal when any part of the worker's body gets an electric shock is extracted synchronously and accurately, and quickly drives the leakage protector or high-power relay or contactor to cut off the power (driving the high-power relay or contactor to cut off the power can also protect people from electric shock , but the reliability is worse, the power-off speed is slower, and the anti-shock effect is worse.)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com