Polishing device

A technology of polishing device and mounting seat, which is applied in the direction of grinding/polishing safety device, surface polishing machine tool, grinding/polishing equipment, etc. It can solve the problems of inability to rotate in multiple directions, time-consuming and labor-intensive, and inability to adapt to various needs. To achieve the effect of convenient and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

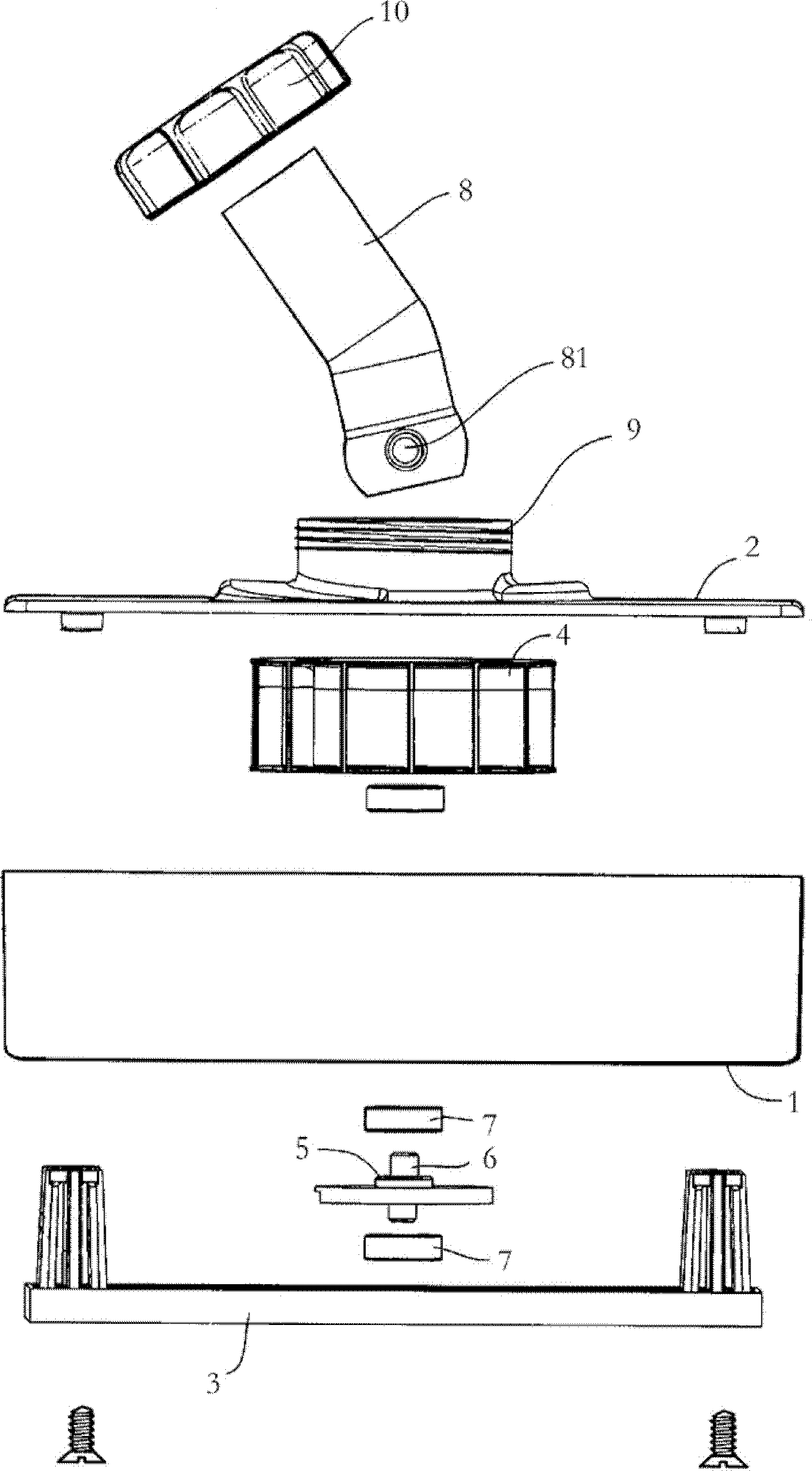

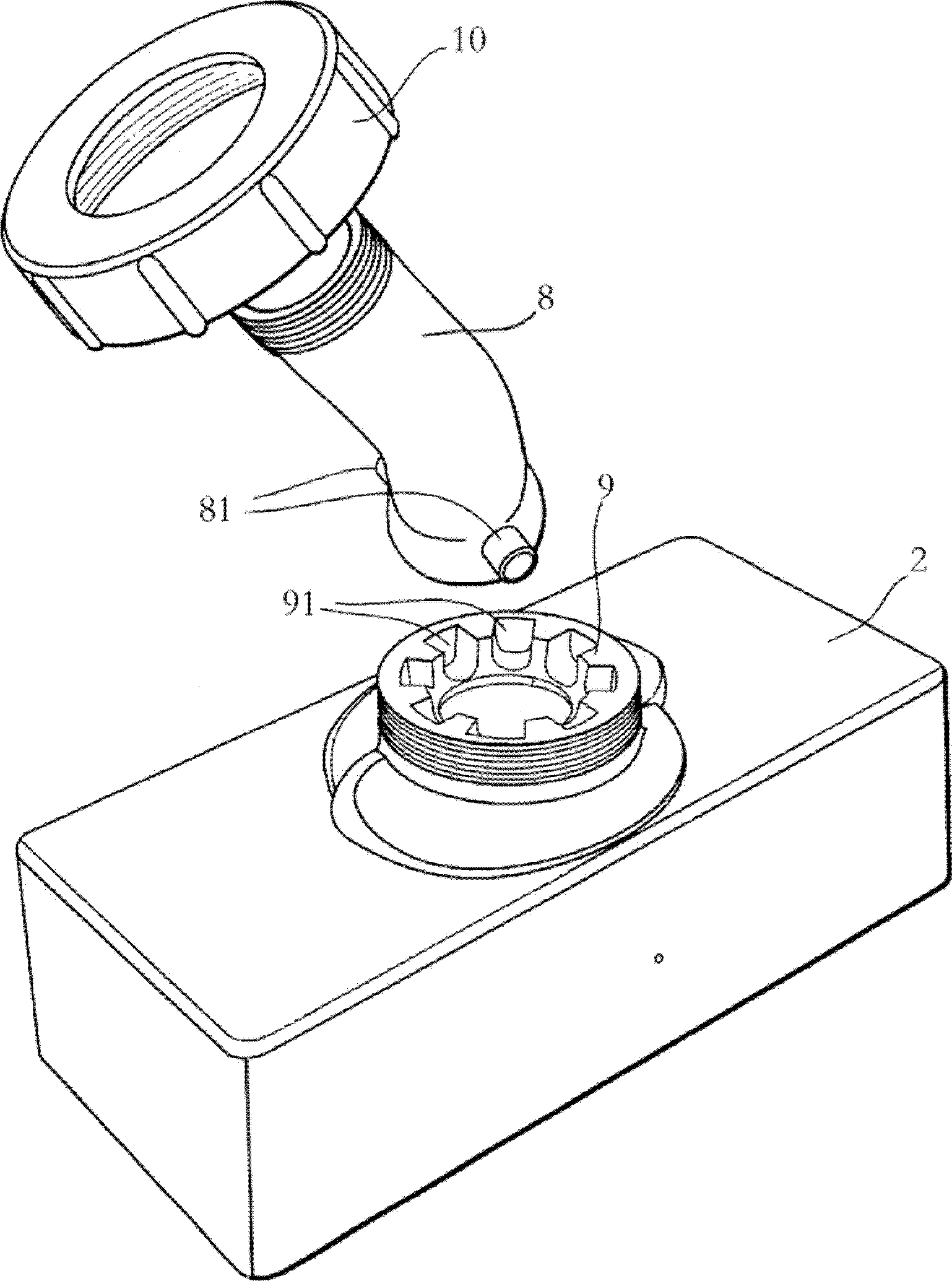

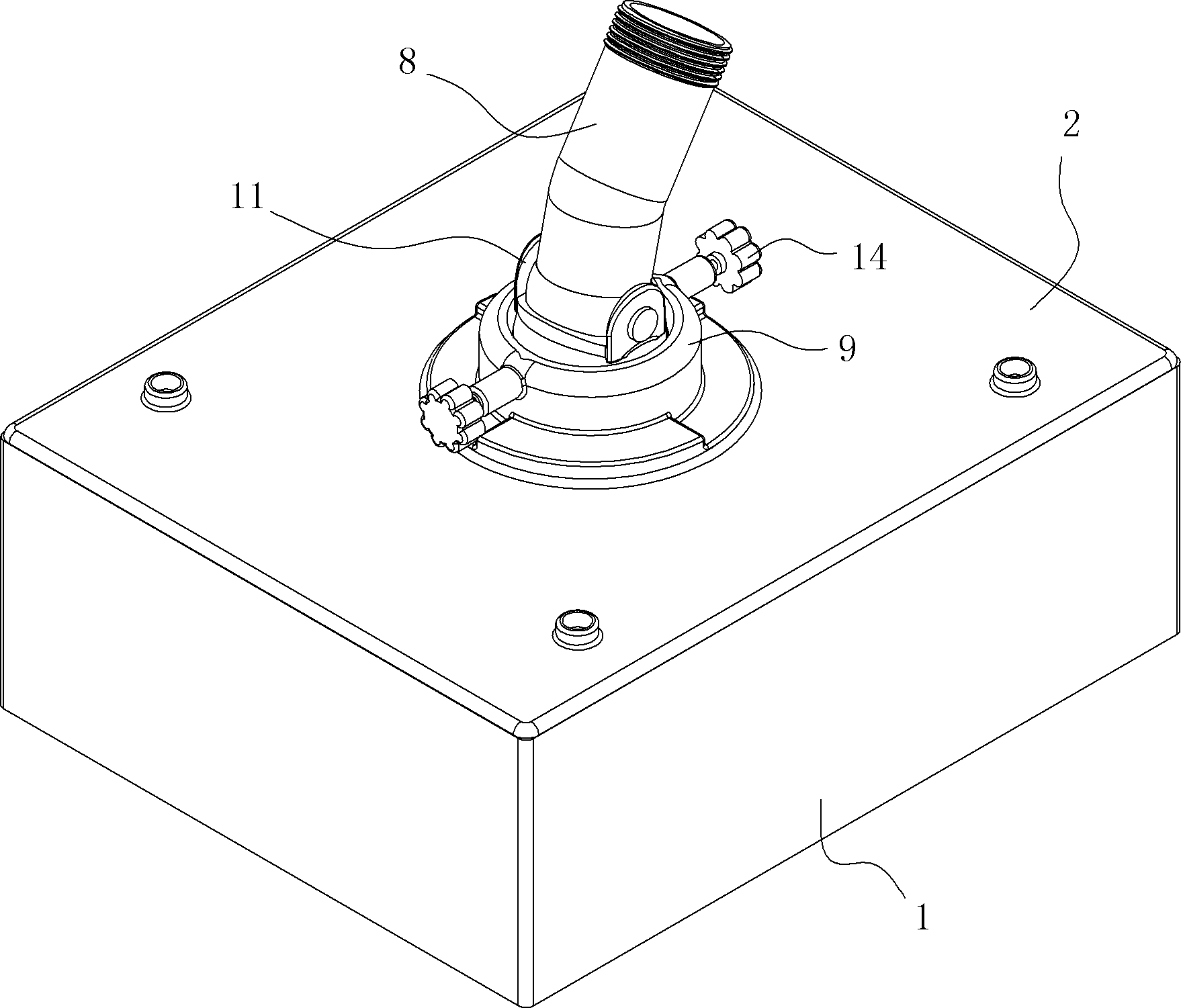

[0024] Embodiment: A kind of polishing device comprises shell 1, shell 1 top has cover plate 2, and shell 1 bottom has polishing chassis 3, and shell 1 is provided with fan blade 4, rotating shaft 6 and is used for driving polishing chassis 3 The moving eccentric disk 5, the cover plate is provided with a connecting pipe rotation mechanism, the connecting pipe rotating mechanism includes a connecting pipe 8 and a mounting seat 9 arranged on the cover plate 2, the bottom of the connecting pipe 8 is horizontally pinned with a joint 11, and the joint 11 There are several pairs of sockets 111 on the peripheral wall, and a pair of opposite elastic pins 12 are provided on both sides of the mounting base 9, and the mounting base 9 is connected with the joint 11 by inserting the elastic pins 12 into a certain pair of sockets 111 of the joint 11. After locking and positioning, pull the two elastic bolts 12 outward, and then the elastic bolts 12 will withdraw from the socket 111 to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com