Method and device for operating composite mixing plant

A working method and a technology of a mixing station, which is applied in the direction of mixing operation control devices, mixing plants, clay preparation devices, etc., can solve the problems of difficult to achieve multiple feeding, small footprint, complex structure, etc., and achieve simple structure and low equipment cost. The effect of low and high batching precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

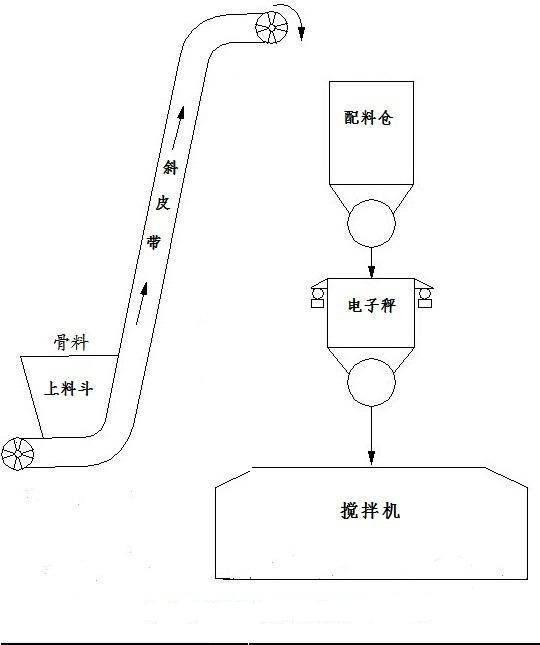

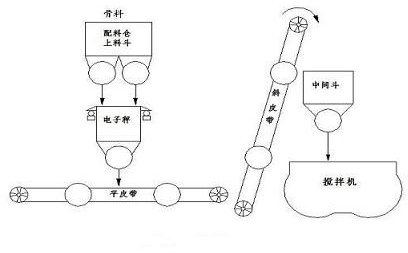

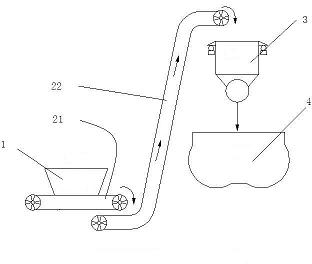

[0024] Further explain the present invention below in conjunction with accompanying drawing in conjunction with embodiment:

[0025] At first, the working method of a kind of preferred composite mixing plant of the present invention is:

[0026] Put the aggregate into the batching bin integrated with the upper hopper; in this step, the upper hopper and the batching bin are combined, which has the advantage of reducing the number of device accessories.

[0027] The aggregates are put into the electronic scale after the batching bin passes through the conveying device to the designated position; in this step, compared with the two existing technical solutions of the first-stage and second-stage, the advantage is to ensure that the equipment has a higher production capacity. At the same time of efficiency, the batching bin or intermediate bucket is omitted, which reduces the height of the entire device, reduces the space required for installation, and reduces the cost of the enti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com