Fixture applicable to loading workpiece during processing of multi-wire cutting machine and fastening method

A multi-wire cutting machine and a technology for processing workpieces. It is applied in the direction of manufacturing tools, work accessories, and stone processing equipment. It can solve problems such as low efficiency and cumbersome steps, and achieve the effect of simple fixing methods and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

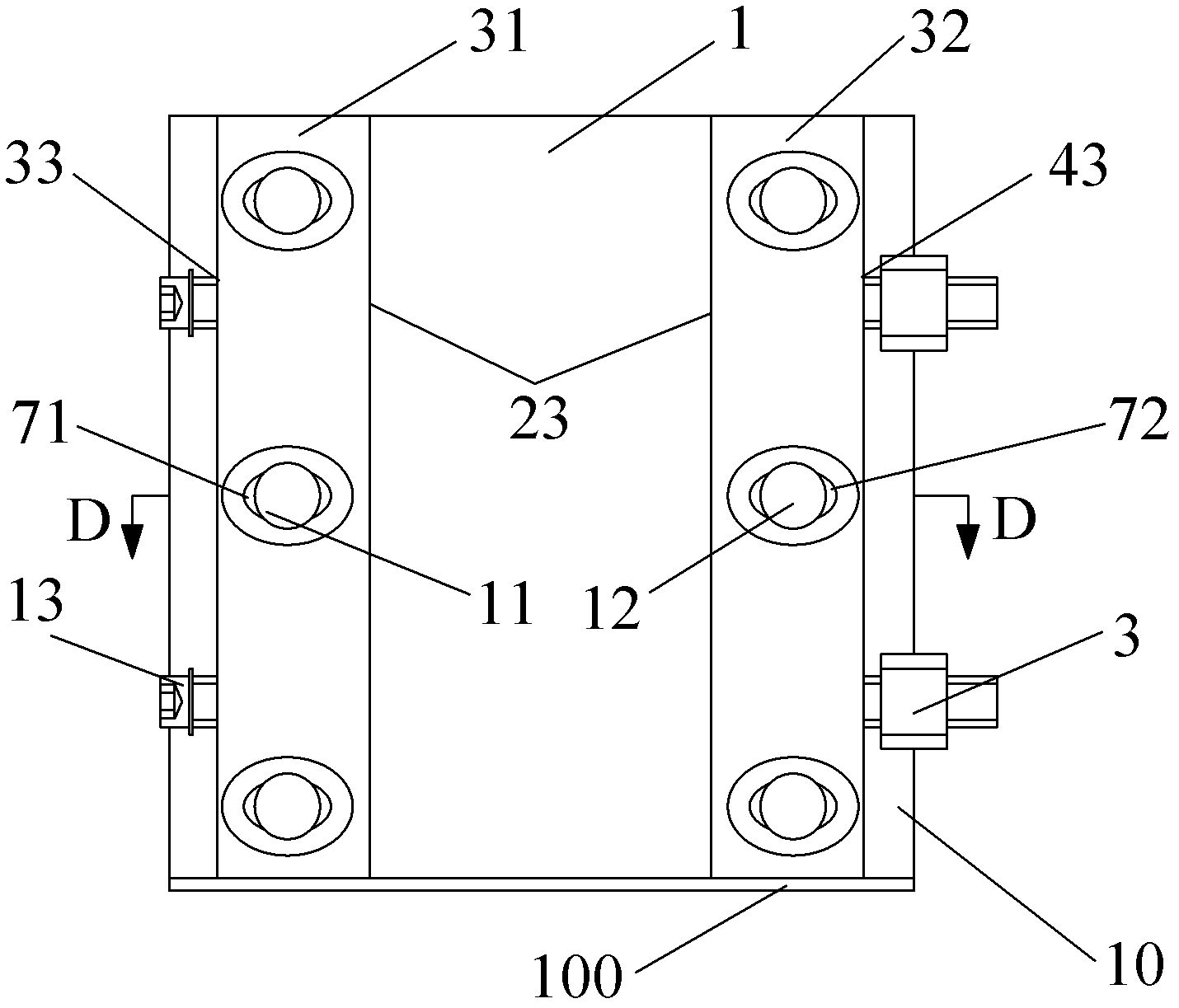

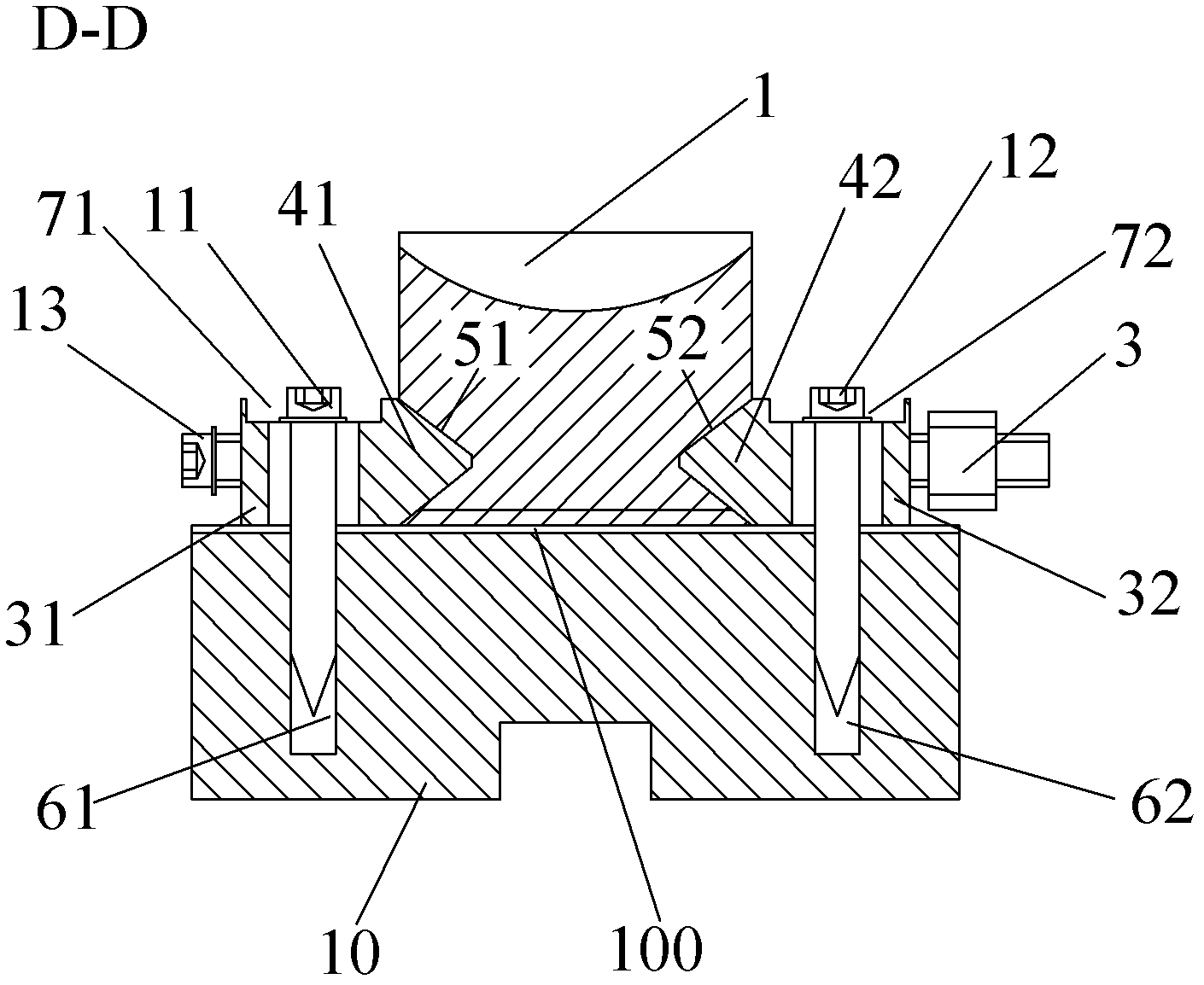

[0029] Embodiment 1, Figure 1 ~ Figure 2 A fixture and fastening method suitable for workpiece loading in multi-wire cutting machining are given. Including processing workpiece pad 1, left fixed steel bar 31, right fixed steel bar 32, fixed screw 13, left fixed screw 11, right fixed screw 12, scale 100 and stainless steel substrate 10.

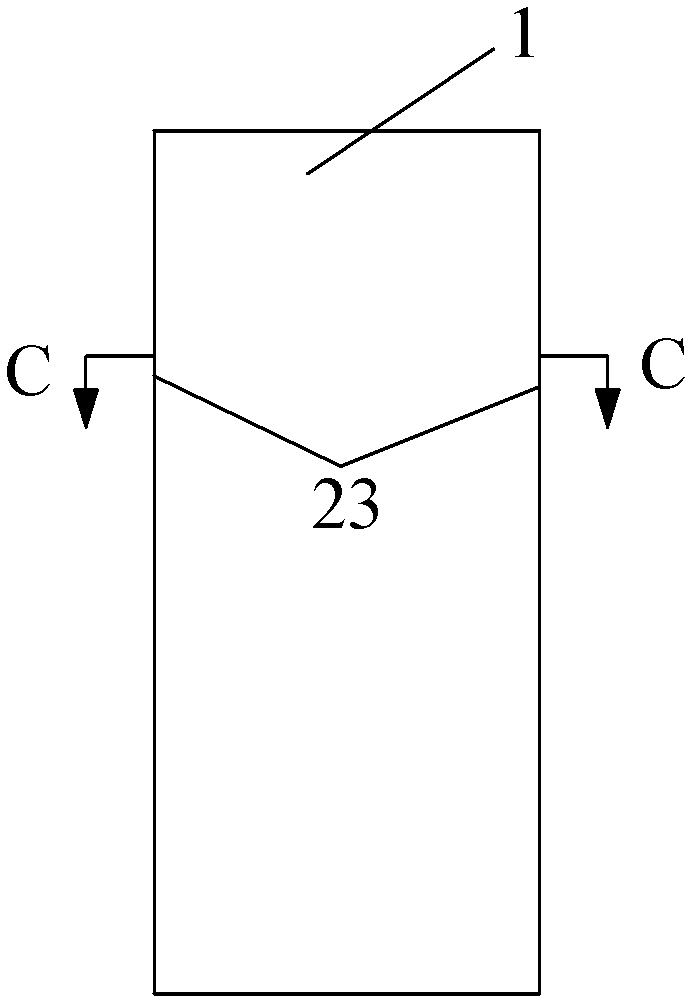

[0030]Have a left groove 51 from front to back on the left side of the workpiece pad 1, and have a right groove 52 from front to back on the right side of the workpiece pad 1 (i.e. the left groove 51 and the right Groove 52 is the same). At least one through hole 23 is opened on the processing workpiece pad 1; the through hole 23 runs through the processing workpiece pad 1 from left to right.

[0031] Corresponding to the left groove 51, the right side of the left fixed steel bar 31 is provided with a left protruding block 41 (the left groove 51 coincides with the left protruding block 41); The steel bar 31 is provided with a left fixed st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap