Comprehensive method of electrical fluid heating system fault detection and handling

A heating system, heating failure technology, used in electric heating devices, air handling equipment, heating/cooling equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

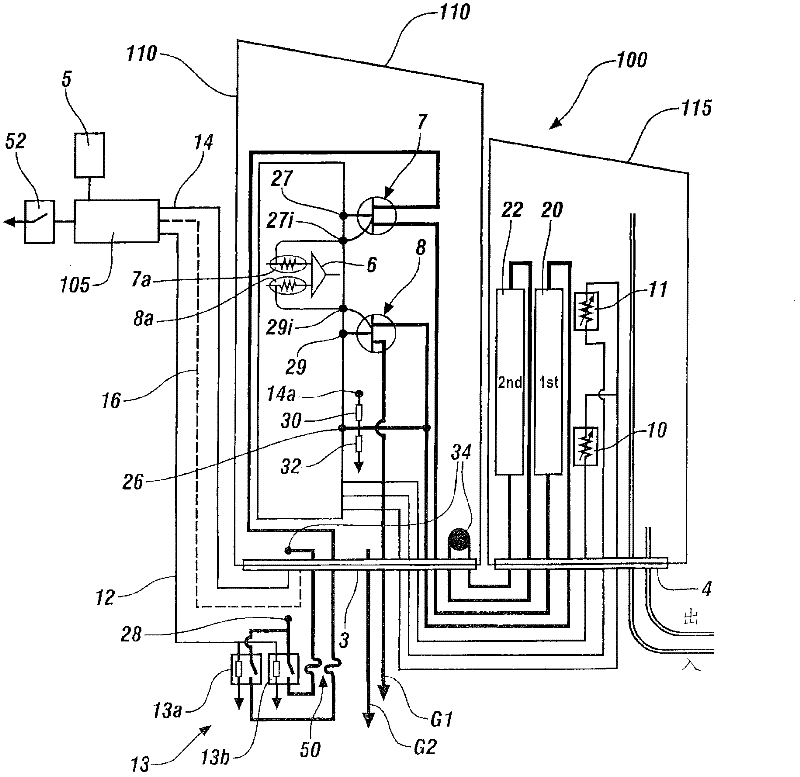

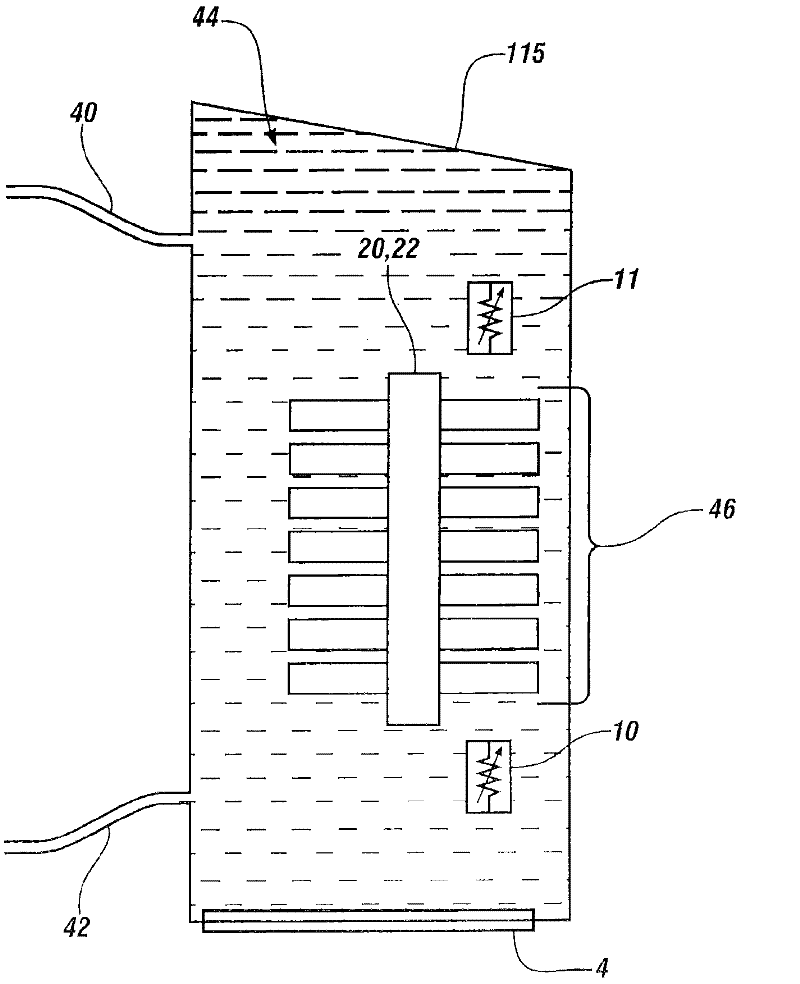

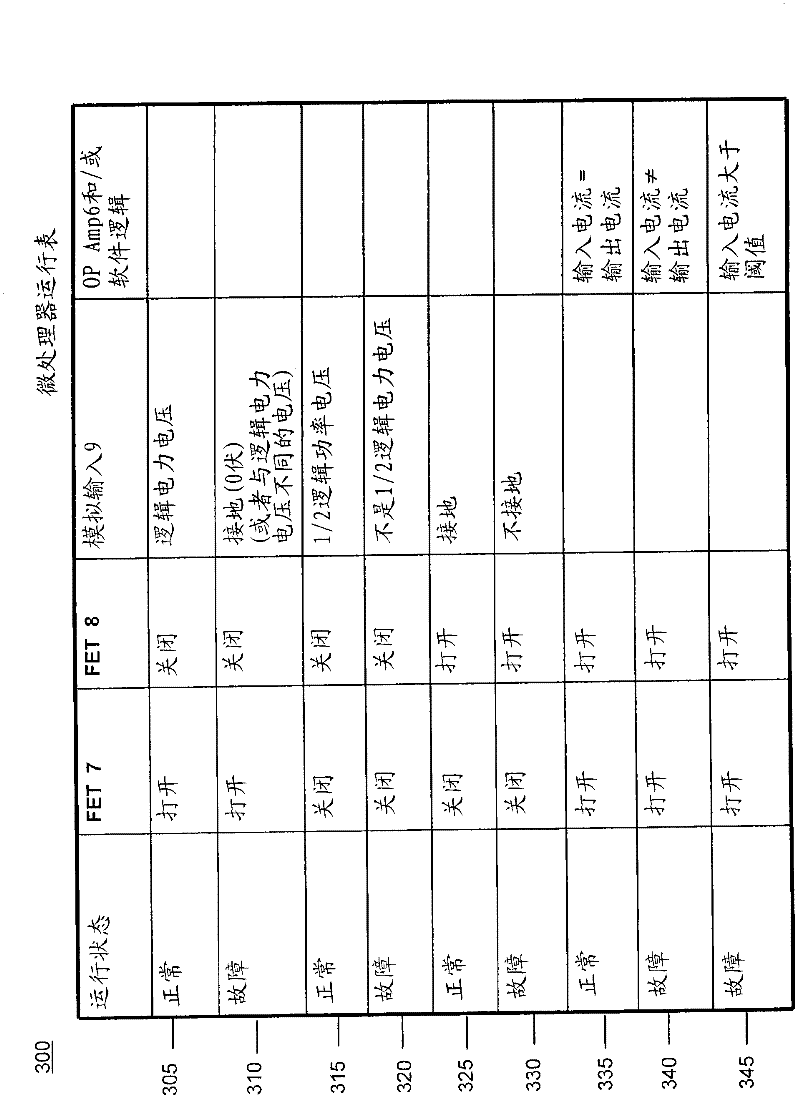

[0073] The following description is merely exemplary in nature and is not intended to limit the invention, its application or uses. It should be understood that throughout the drawings, corresponding reference characters indicate like or corresponding parts and features.

[0074] According to an exemplary embodiment of the present invention, the present invention provides a method and system for eliminating out-of-spec temperature operation associated with an electric heating device. The exemplary embodiment describes an electric heating system, but is applicable to other sensing and control structures for automotive electric loads where thermal operation may be present.

[0075] According to an exemplary embodiment of the present invention, an electrical heating system combines several layers of thermal detection strategies to form a unique comprehensive approach to preventing and detecting potential electrical thermal conditions that, if undetected and / or uncontrolled, could...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com