Inertial power engine with motor structure

A motor structure and technology with a motor, which is applied in the field of vehicle engines and can solve problems such as poor acceleration, high energy storage density, and weakened expectations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

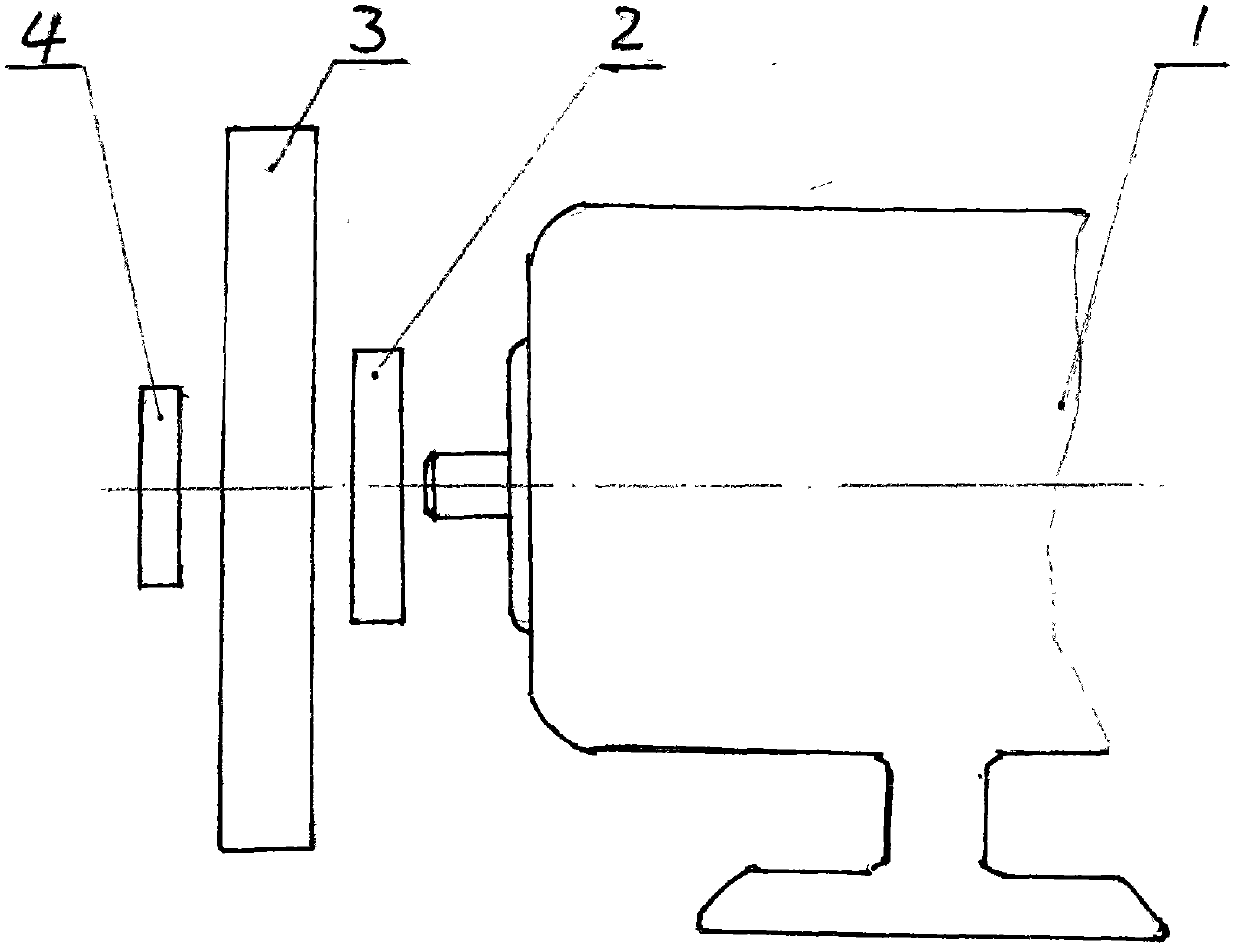

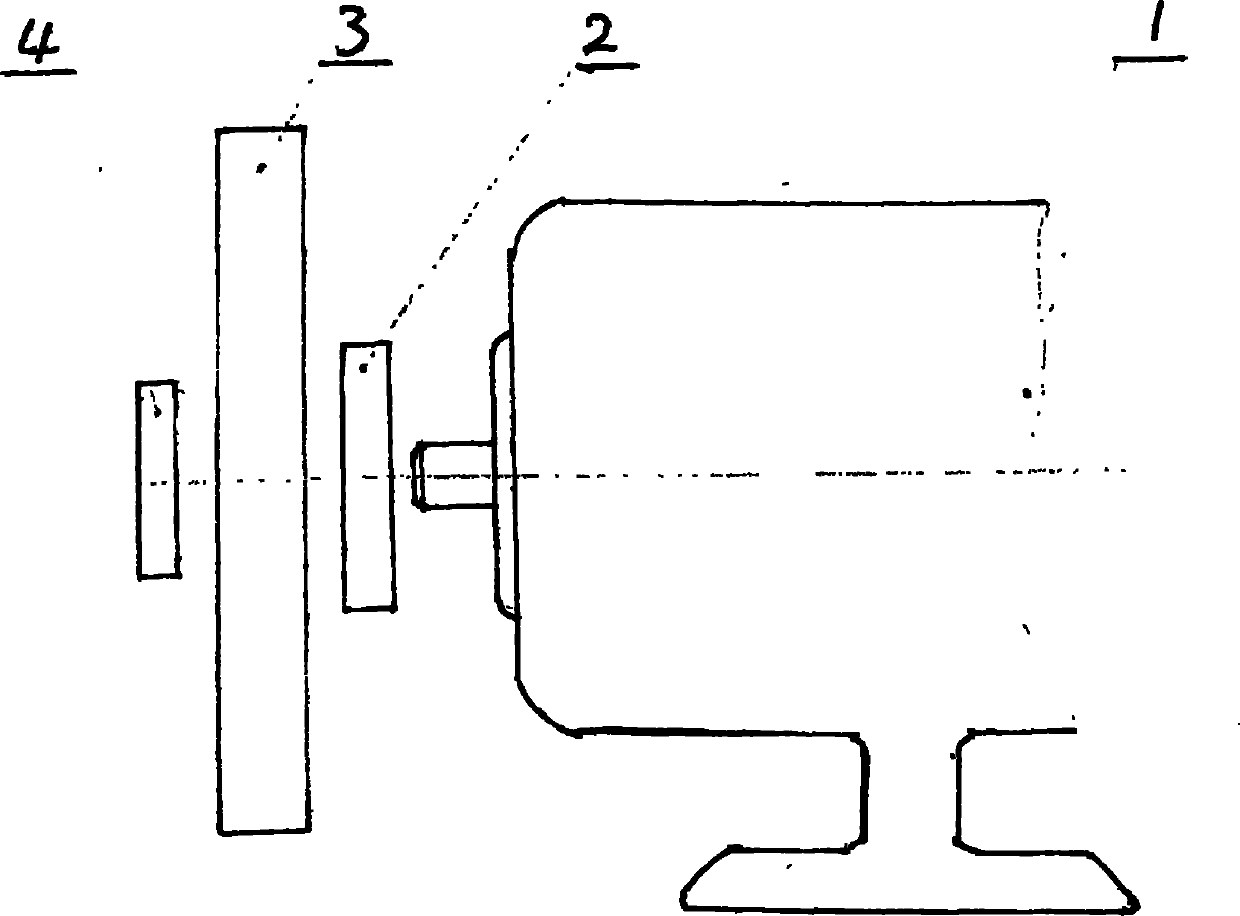

[0017] exist figure 1 Among them, the inertial power engine with motor structure adopts the vehicle-mounted motor structure mode, and one or both ends of the vehicle-mounted motor (1) are connected synchronously or accelerated to the flywheel A (3) through the connector (2), so that the flywheel speed can have a high release speed. The design requirement of instantaneous power is to transmit the inertial power through the external clutch (4). The main difference between it and the vehicle-mounted motor engine is that it has a flywheel and related connectors.

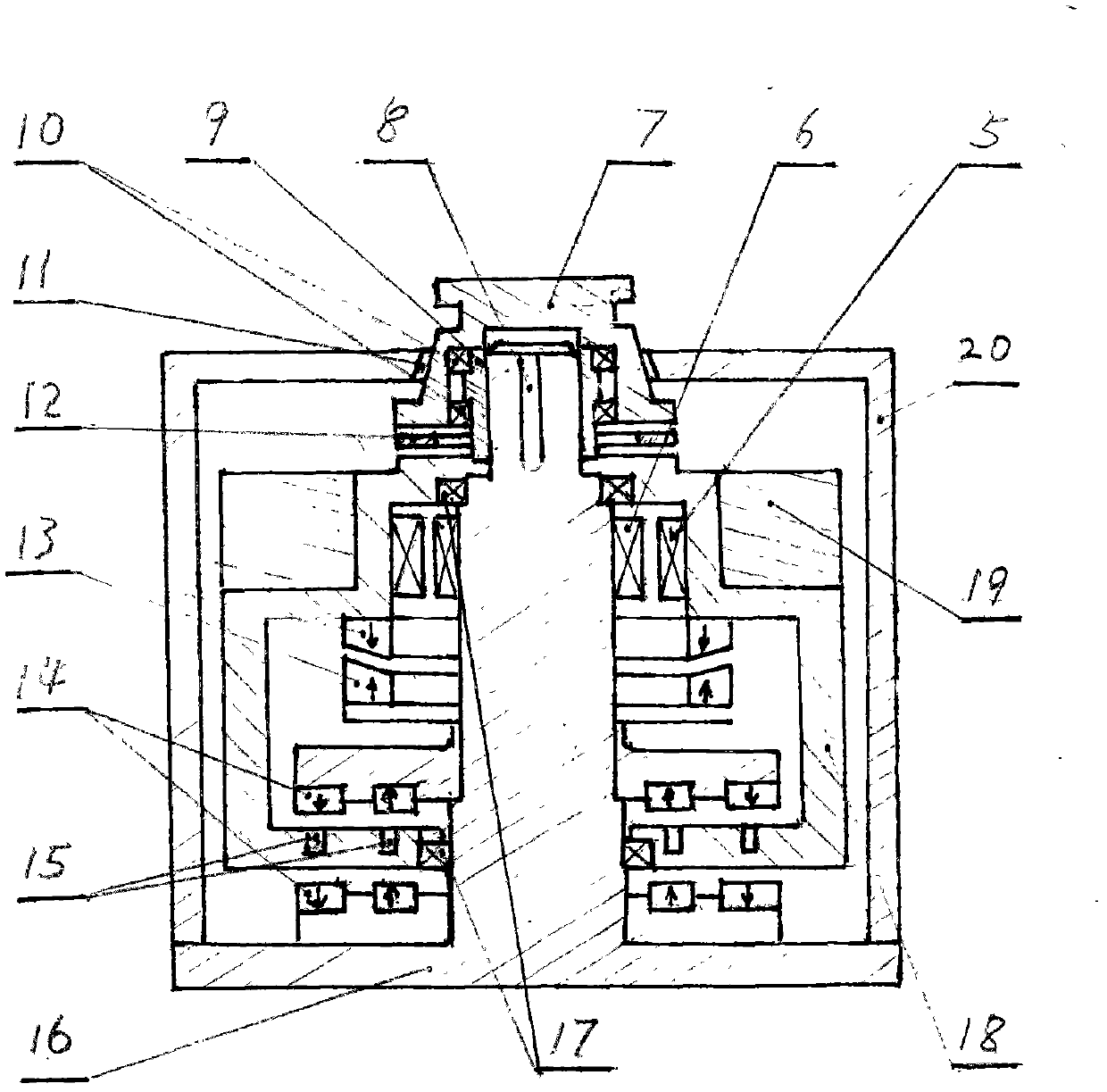

[0018] exist figure 2 Among them, when the "flywheel battery" motor structure mode is adopted, the motor rotor (5) is fixed on the flywheel B (18), and the motor stator (6) is fixed on the main support body (16). The ring constitutes an axial magnetic suspension bearing (13), and the magnetic field member (14) and the conductor ring (15) form a radially constrained electromagnetic force support. The opening of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com