Water treatment system

A technology of water treatment system and water recovery tank, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, mechanical oscillation water/sewage treatment, etc. , the liquid level fluctuated high and low, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

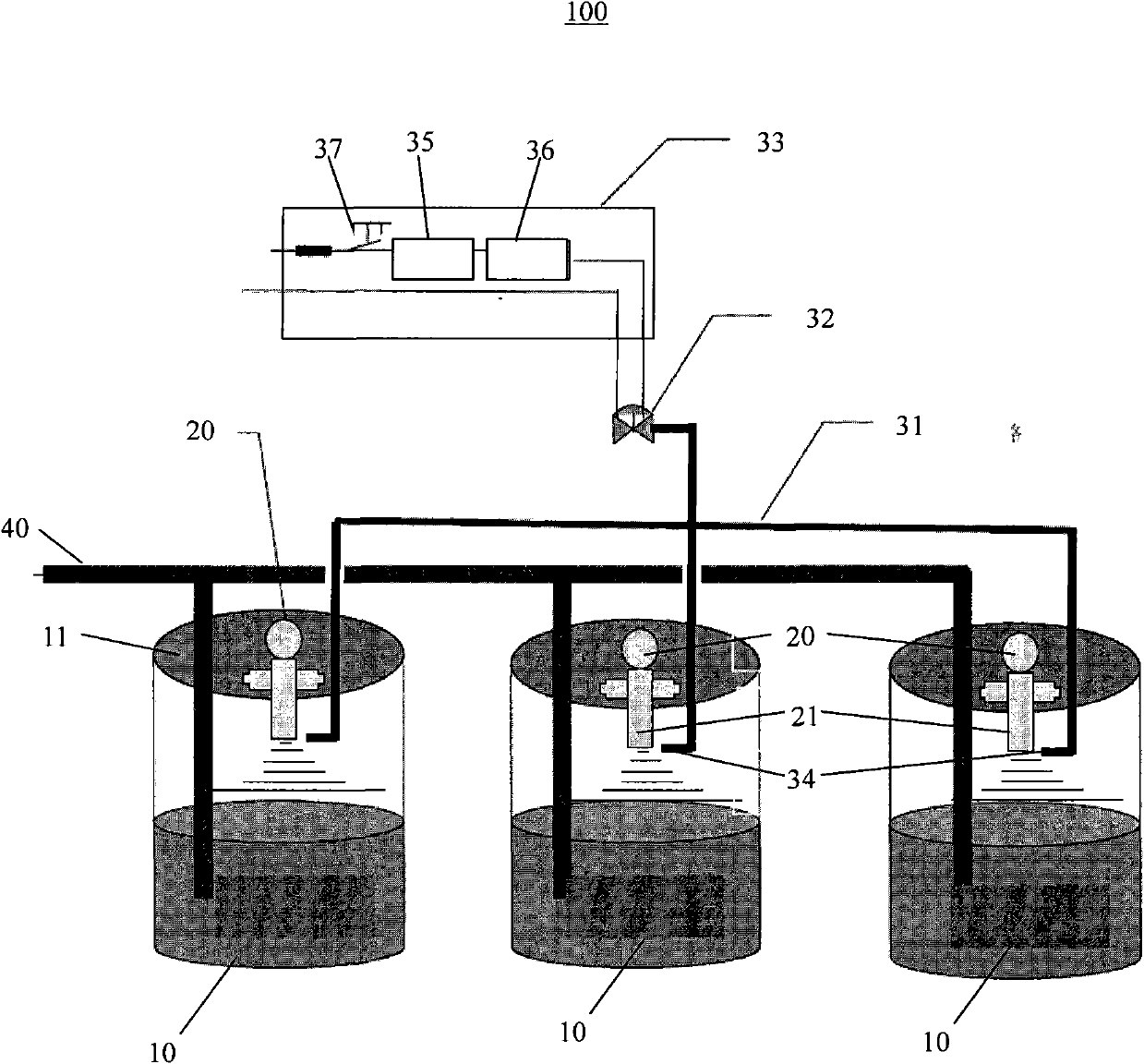

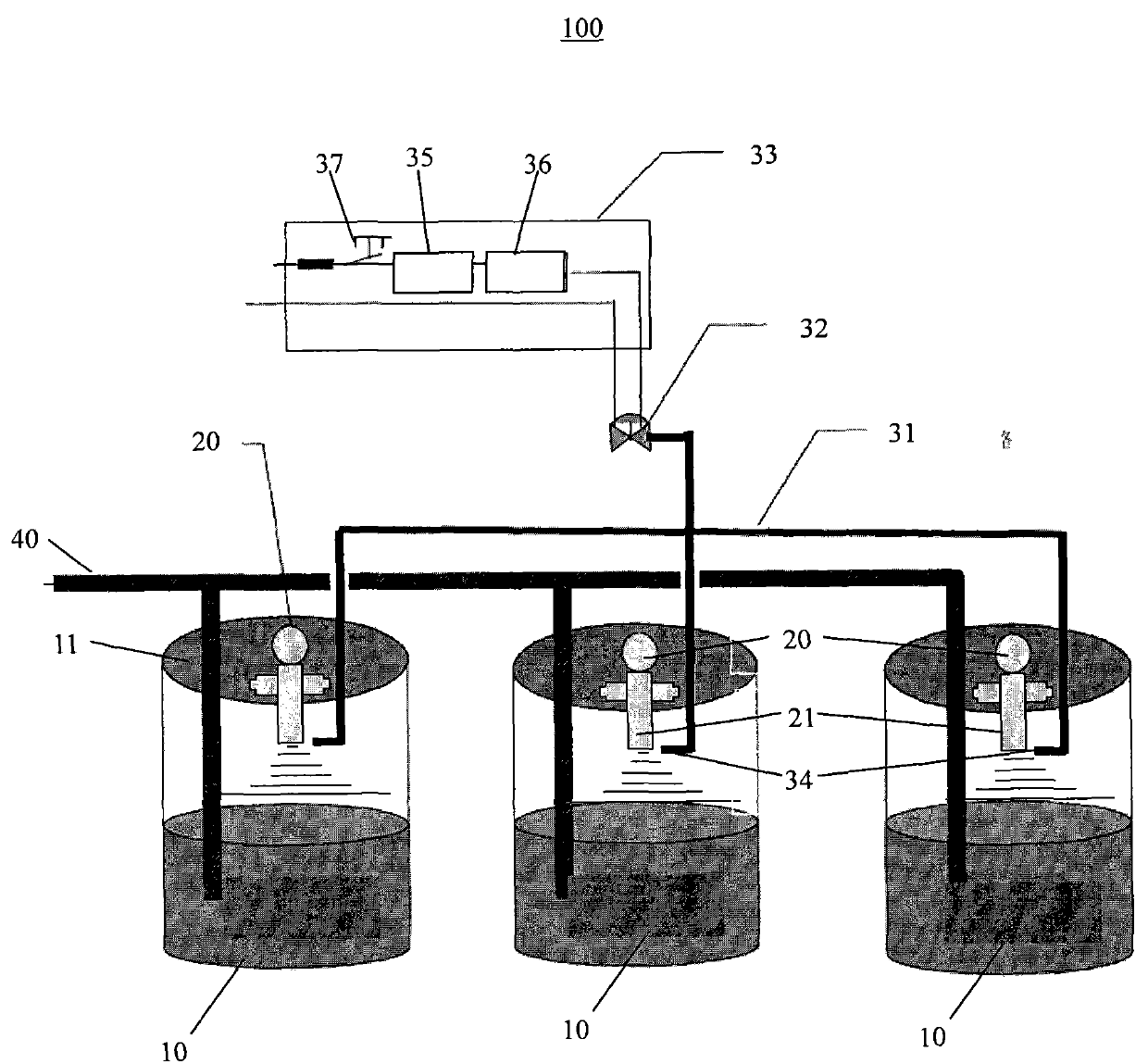

[0011] Please refer to figure 1 As shown, the present invention provides a water treatment system 100, which includes a number of recovery water tanks 10, liquid level gauges 20 located in the recovery water tanks 10, purging devices 30 connected to the liquid level gauges 20, and connected to each recovery water tank. 10 for 40 pipes.

[0012] The recycling water tank 10 is cylindrical, and is used to contain the water from the pipeline 40 . The recycling water tank 10 is provided with a circular top cover 11 .

[0013] The liquid level gauge 20 is an ultrasonic liquid level gauge, which is installed on the circular top cover 11 and is provided with a probe 21, and the probe 21 is used to emit ultrasonic waves and receive the reflected ultrasonic waves. The ultrasonic wave emitted by the probe 21 will be reflected to the probe 21 when encountering the water surface in the recovery water tank 10, and the liquid level gauge 20 calculates the time difference between the ultraso...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap