Weaving method for woven handle of handbag

A technology for carrying handles and bags, applied in the directions of woven fabrics, textiles and papermaking, can solve the problems of inability to meet diversified needs, the influence of the appearance of the bags, and the complicated oil edge operation procedures, so as to achieve a beautiful appearance and a three-dimensional sense. , bearing a heavy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

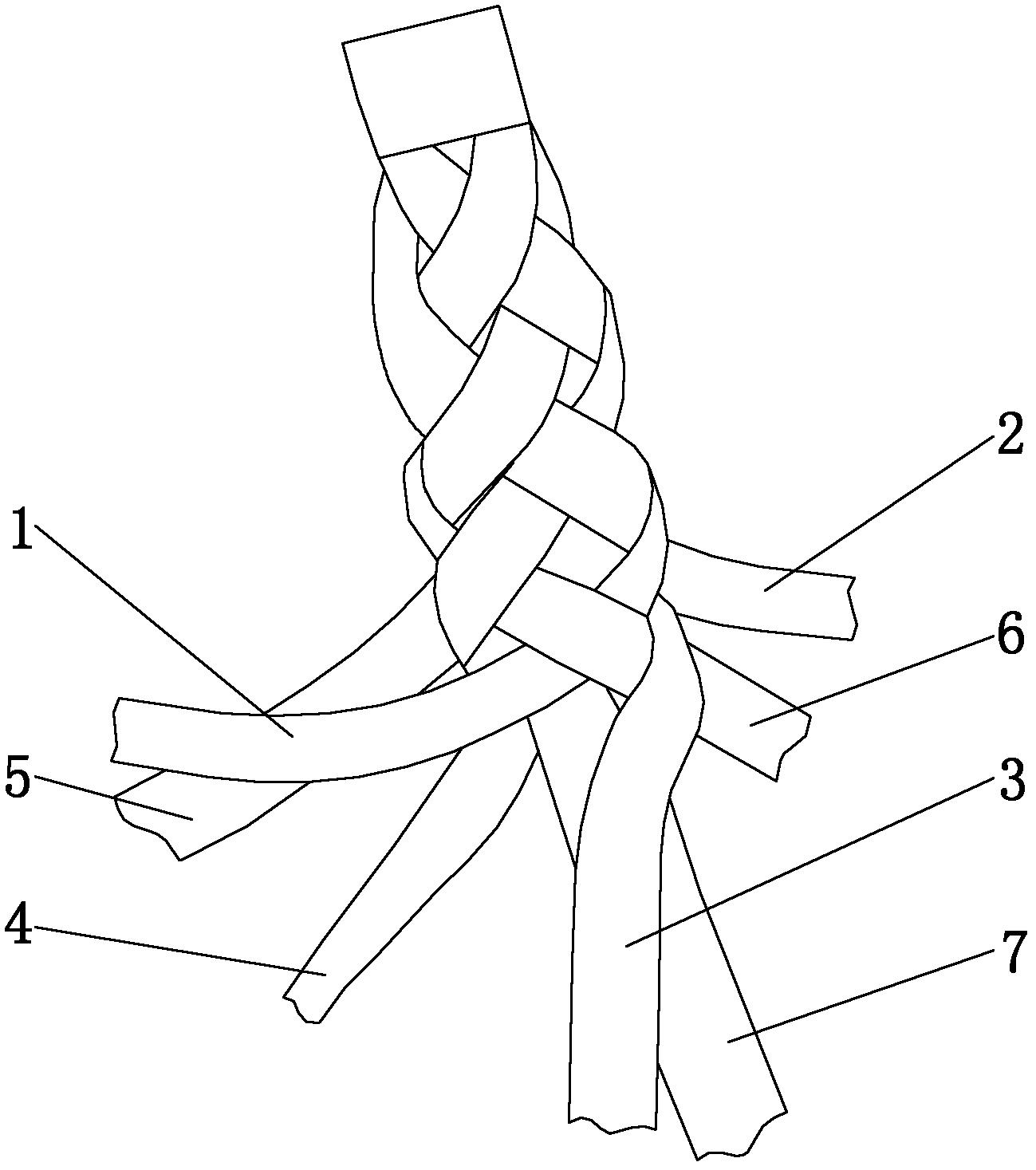

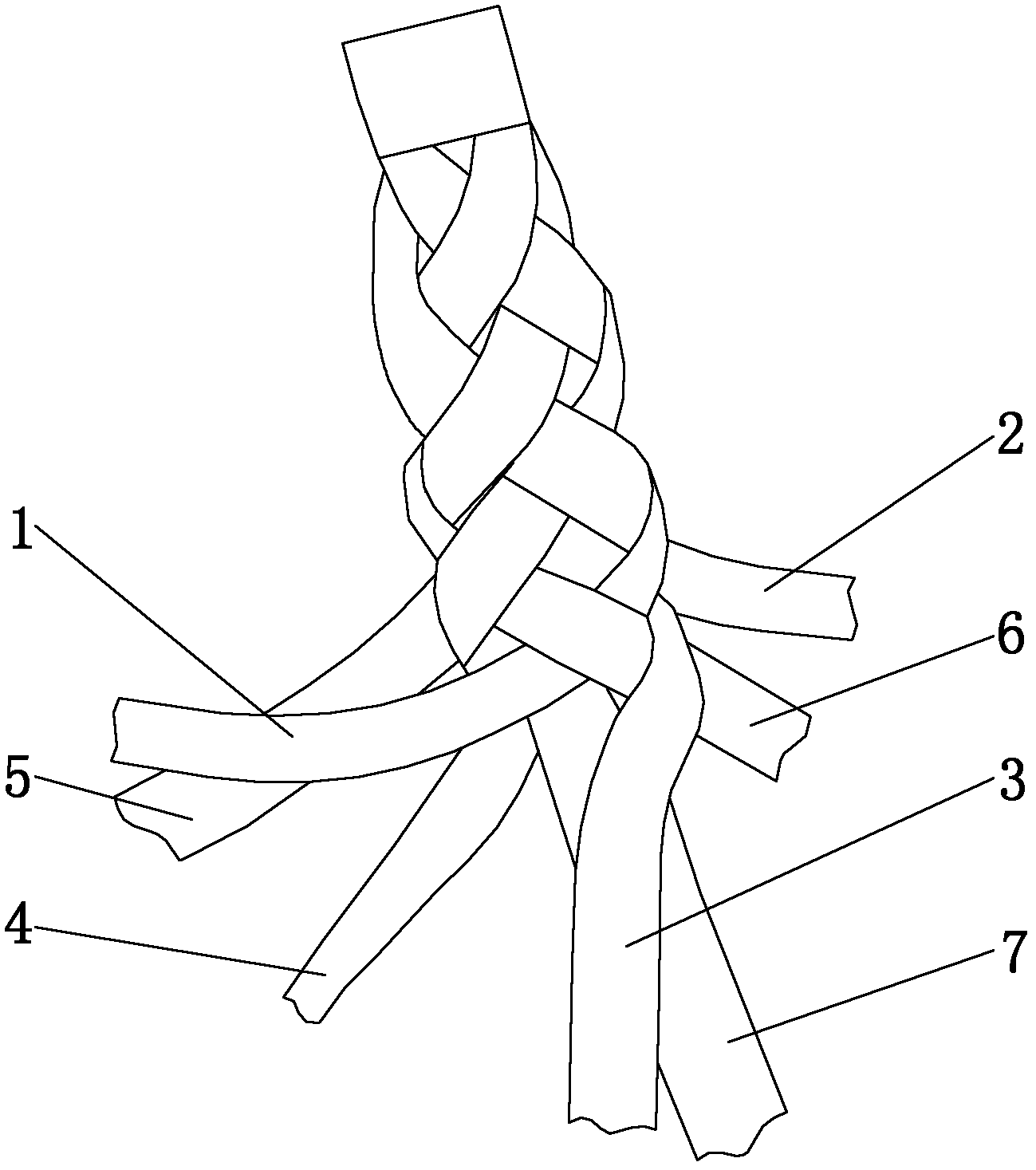

[0018] Such as figure 1 Shown is an example of a braided handle with six straps wrapped around a core.

[0019] 1) Wrap six straps 1, 2, 3, 4, 5, 6 with the same width around the core strip 7, and then tie the wrapping place tightly;

[0020] 2) Make the two adjacent tapes 1 and 2 cross-mask. At this time, tape 1 is adjacent to tape 3, and tape 2 is adjacent to tape 6; then cross-mask tape 1 and tape 3, and tape 2 and tape 6 cross masking; in this way, tape 1 is adjacent to tape 4, and tape 2 is adjacent to tape 5; continue to cross masking of tape 1 and tape 4, and cross masking of tape 2 and tape 5; according to the above operations, respectively The adjacent two straps are intersected and pressed, and are braided around the core strip 7 to form a cylindrical braided handle body;

[0021] 3) After the braiding is completed, tie the tapes 1, 2, 3, 4, 5, 6 and the core strip 7 tightly, and cut off excess tapes to obtain the braided handle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com