Drum type washing machine

A drum washing machine, drum technology, applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of clothes not being able to achieve cleaning performance, insufficient detergent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

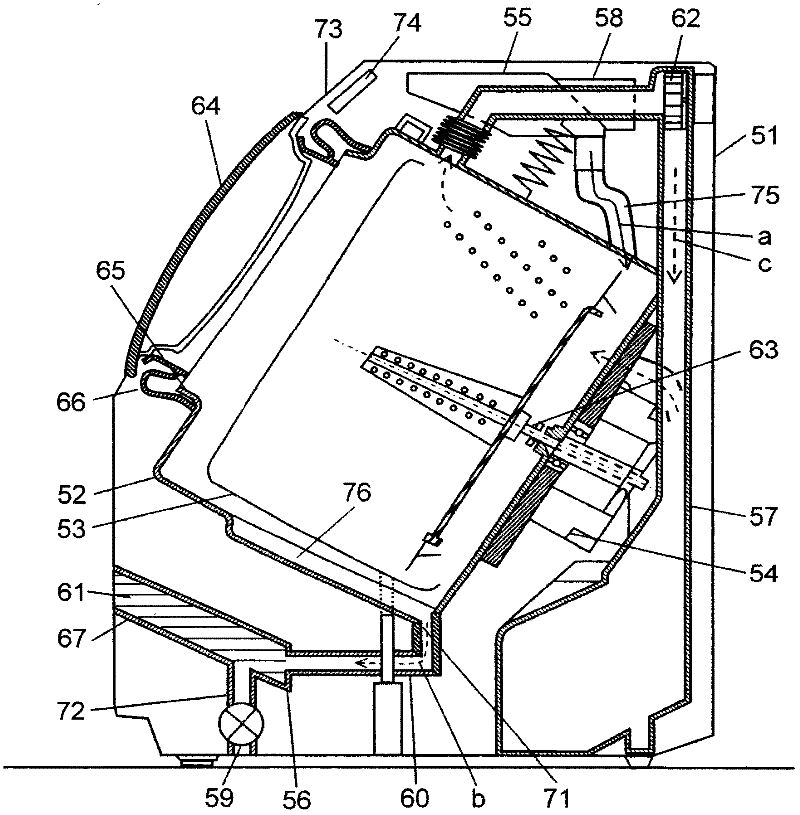

[0020] figure 1 It is a longitudinal sectional view of the front-loading-type washing machine in Embodiment 1 of the present invention.

[0021] like figure 1 As shown, the inside of the washing machine body 51 of the front-loading washing machine in this embodiment at least includes: a water holding cylinder 52 arranged to shake freely; , and the motor 54 that is located at the back side outside of the water storage tube 52. The rotary drum 53 is driven by a motor 54 . On the inner side wall of the lower part of the water tank 52 , along the direction of the rotating shaft 63 of the rotary drum 53 , there is provided a concave drainage groove 76 , and a drainage outlet 71 is arranged in the concave drainage groove 76 .

[0022] In addition, the drum type washing machine of this embodiment has the following functions, that is, the control unit 74 controls the washing machine according to the set operation mode and control program. figure 1 The motor 54, water supply sys...

Embodiment 2

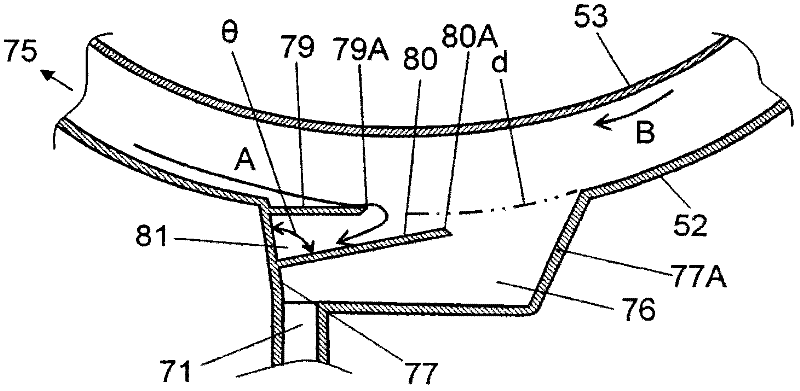

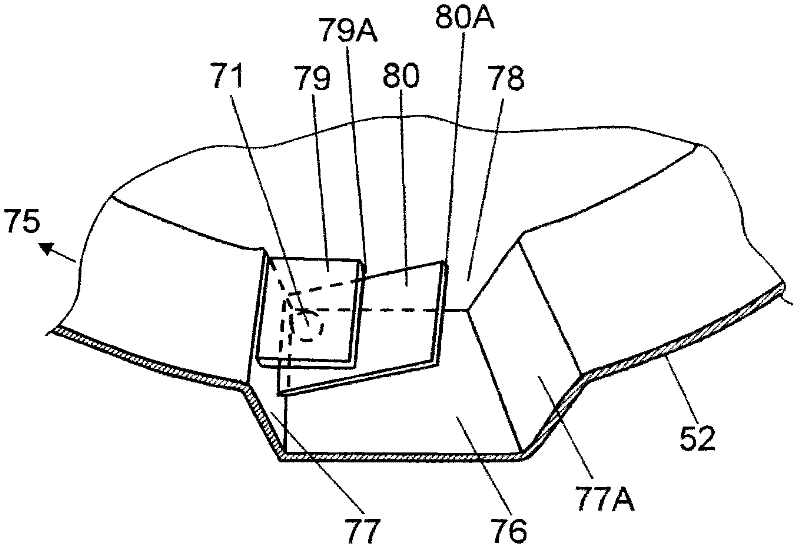

[0048] Combine below Figure 3A and Figure 3B A drum type washing machine according to Embodiment 2 of the present invention will be described.

[0049] Figure 3A It is a front sectional view of the structure at the drain tank of the drum type washing machine according to Embodiment 2 of the present invention, Figure 3B Yes Figure 3A partial perspective view of .

[0050] like Figure 3A and Figure 3B As shown, the difference between the front-loading washing machine of this embodiment and Embodiment 1 is that: the lower extending flange 82 extends from the side wall 77 of the water supply pipeline 75 side of the drain tank 76 toward the opposite side wall 77A, and The short side 83 of the drain tank 76 on the water supply line 75 side and the long side 84 on the side opposite to the water supply line 75 side of the drain tank 76 substantially constitute a V-shape (including the V-shape). Furthermore, it is different from the first embodiment in that a gap 85 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com