Deepwater pressure-proof circular-opening flange butt-joint deadlock kickoff mechanism

A technology of release device and round mouth, which is applied in the direction of flange connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve the problems such as the difficulty of locking and releasing, and achieve safety and reliability, cost reduction, and strong molding Technological effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

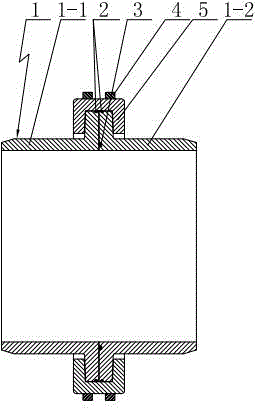

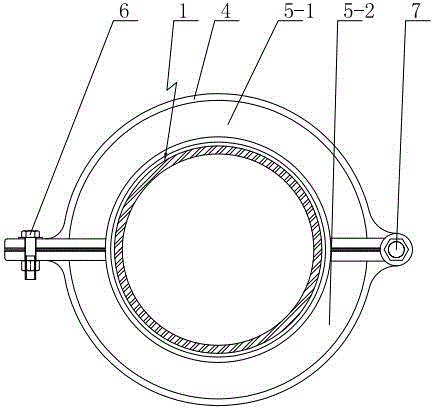

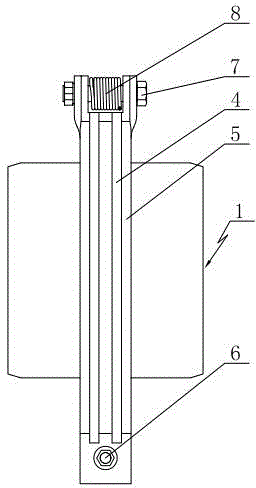

[0020] Such as figure 1 with figure 2 As shown, the deep-sea pressure-resistant round-mouth flange butt lock release device of the present invention includes a pressure-bearing cylinder 1, which is formed by welding the flange 1-1 and the flange 1-2, And the butt joint surfaces at both ends are respectively sealed by sealing rings 3, and the two ends of the pressure bearing cylinder 1 form a raised round mouth end after they are butted; Two rings of reinforcing ribs 4 are arranged on the outer circumference of the clamp ring 5 to increase the strength of the clamp ring 5 and improve reliability; the clamp ring 5 is divided into an upper half clamp ring 5-1 and a lower half clamp ring 5 -2. After the upper half of the clamp ring 5-1 and the lower half of the clamp ring 5-2 are docked and installed, their two ends form a concave circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com