Defrosting system of evaporator of low-temperature storeroom for ship

An evaporator and low-temperature technology, which is applied in the field of defrosting system of marine low-temperature storage evaporators, can solve problems such as inability to melt frost, low power, ice blockage in downpipes, etc., to improve operational reliability, reduce replacement frequency, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

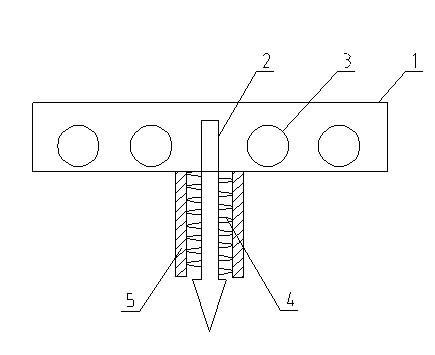

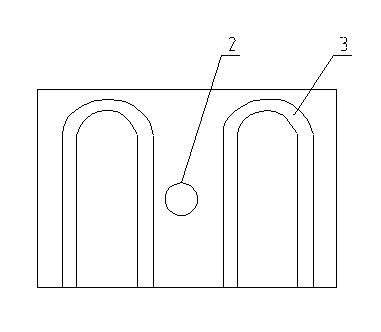

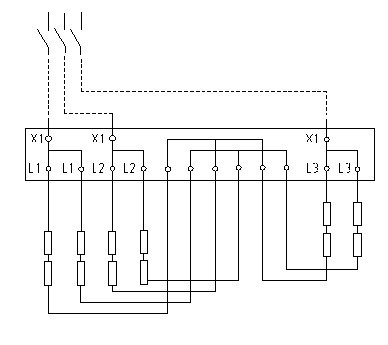

[0029] see figure 1 , figure 2 and Figure 4 , the present invention relates to a marine low-temperature storage evaporator defrosting system, which includes an evaporator, a water collecting pan 1 and a downpipe 2, the water collecting pan 1 is arranged at the bottom of the evaporator, and the downpipe 2 is installed on the water collecting pan 1 At the bottom, the evaporator includes six sets of defrosting heating tubes 6, each set of defrosting heating tubes 6 has two, the two defrosting heating tubes 6 are connected in parallel, and the six sets of defrosting heating tubes 6 adopt a star shape Connected, two U-shaped electric heating tubes 3 are arranged in the water collecting tray 1, heating wire 4 is evenly wound on the outer wall of the downspout 2, and a heat preservation tube 5 is arranged on the outer side of the heating wire 4, and the defrosting heating tube 6. U-shaped electric heating tube 3 and heating wire 4 are synchronously interlocked and controlled.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com