Feeding device for drying cylinder of dryer

A technology of feeding device and drying cylinder, which is applied in the direction of drying, drying solid materials, lighting and heating equipment, etc., which can solve the problems of non-wear-resistant and easy-to-block materials in the feed pipe, so as to prolong the service life and prevent blockage The effect of simple material and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through specific embodiments.

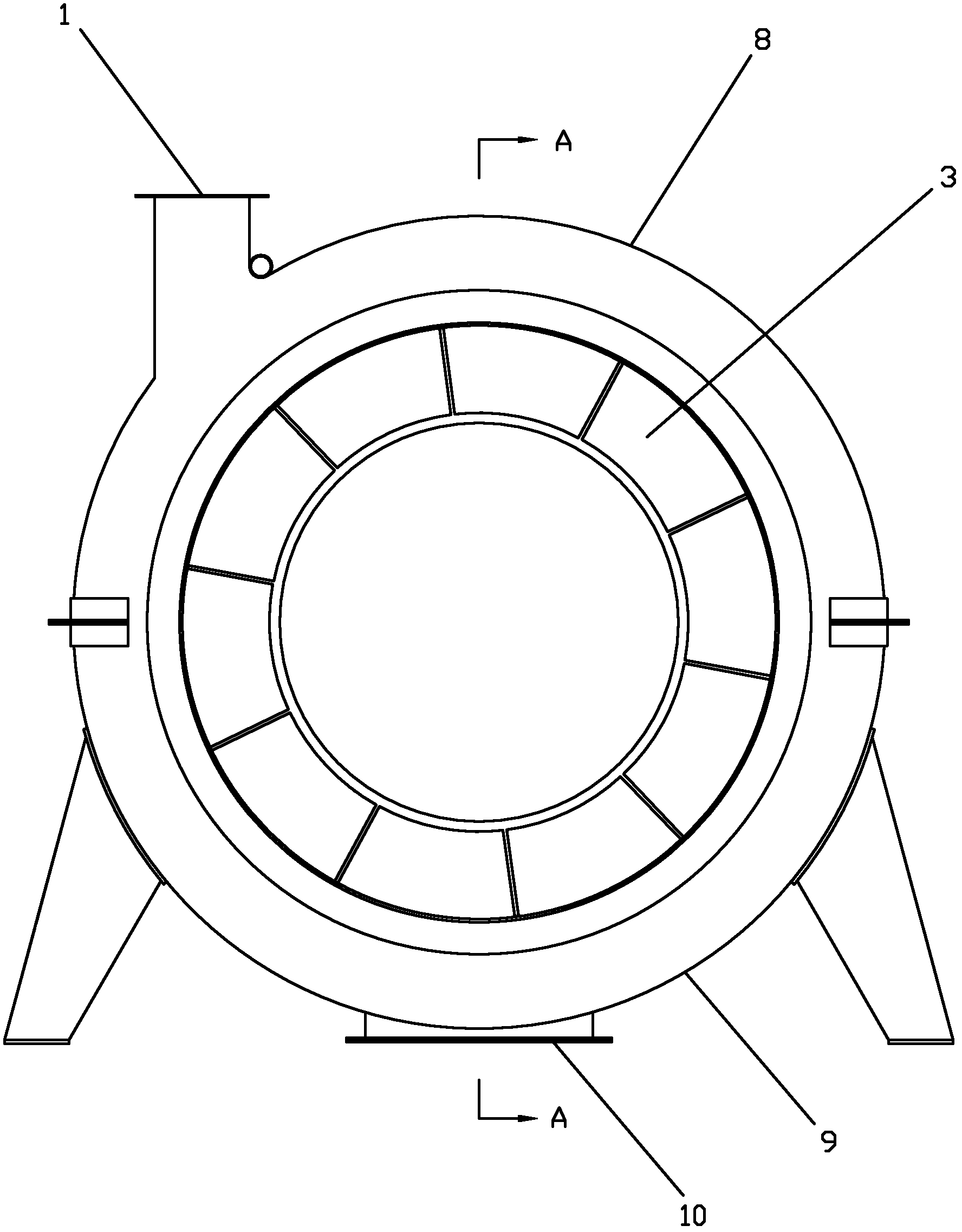

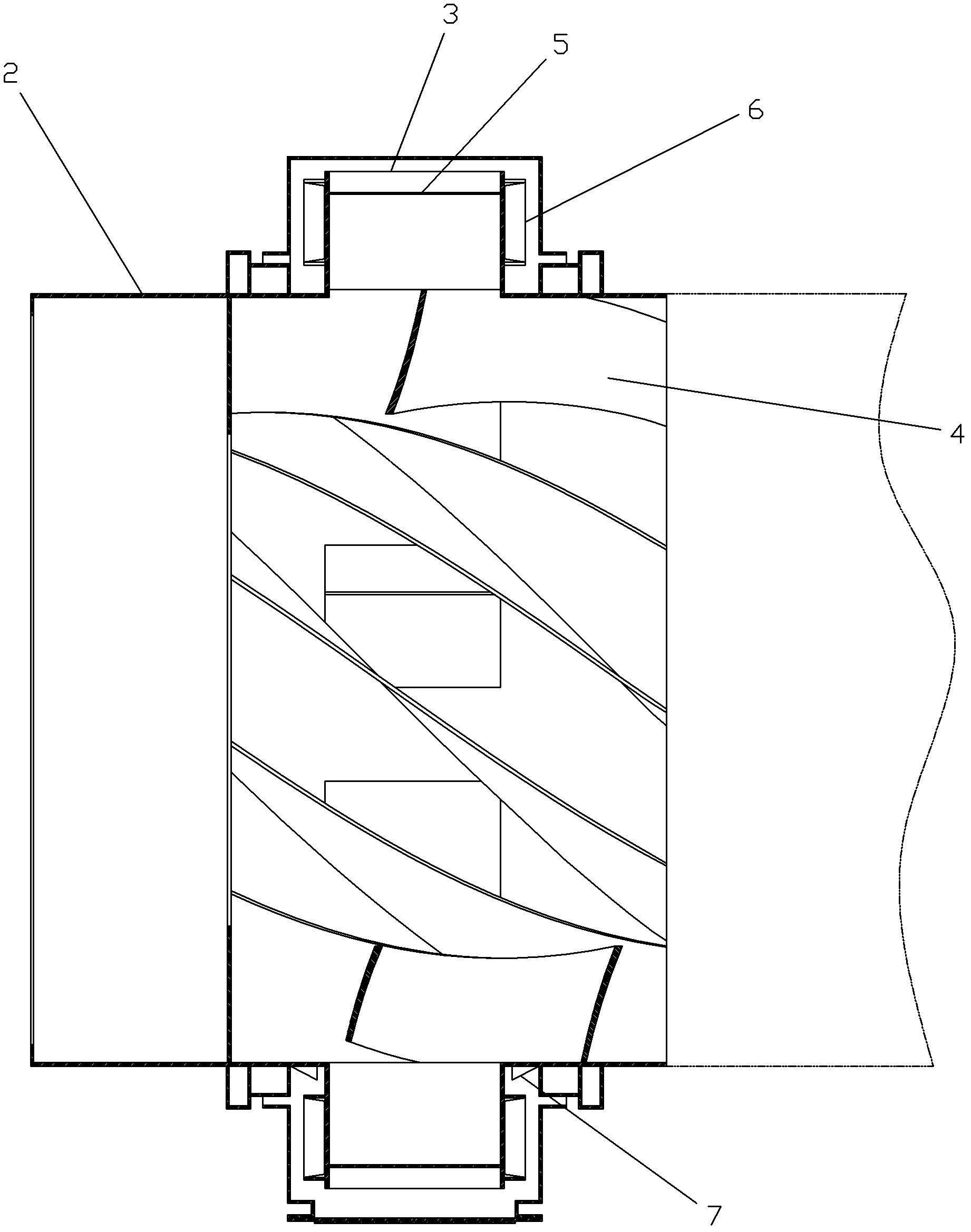

[0016] refer to figure 1 and figure 2 , a drying drum feeding device for a dryer, comprising a housing, a feeding pipe 1 arranged above the housing, a feeding cylinder 2 arranged inside the housing, and a feeding tube connected to the outer periphery of the feeding cylinder 2 A set of blanking hoppers 3, a set of spiral material guide plates 4 connected to the feeding cylinder 2, wear-resistant lining plates 5 embedded in the inner wall of the blanking hopper 3, and materials on both sides of the blanking hopper 3 are introduced into the blanking hopper 3. Lateral blanking device inside. The lateral blanking device includes a lateral guide hopper 6 connected to both sides of the blanking hopper 3 and a lateral material shifting plate 7 connected to the feeding cylinder 2, and the lateral guide hopper 6 communicates with the blanking hopper 3 . The casing includes an upper casing 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com