Method and intelligent force-measuring supporting seat for monitoring bridge health

A healthy and bridge technology, applied in the direction of measuring the change force of optical properties of materials when they are stressed, can solve the problems of inconvenient detection work, danger, small headroom, etc., and achieve simple measurement methods, good durability, and improved The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments to help understand the application of the present invention, but the protection scope of the present invention is not limited to this specific embodiment.

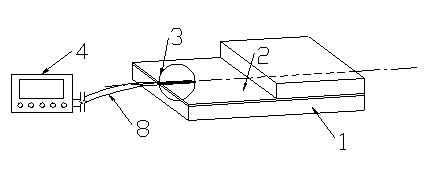

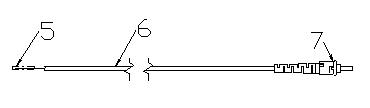

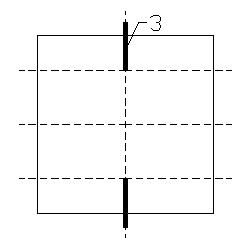

[0020] refer to Figure 1~3 , an intelligent force-measuring bearing for bridge health, comprising a plate-type rubber bearing 1, characterized in that: the plate-type rubber bearing 1 is equipped with a force-measuring element, and the force-measuring element includes a plurality of The axial pressure and shear force and the optical fiber strain sensor 3 that is symmetrically arranged in the plate rubber bearing 1, the optical fiber strain sensor 3 is connected to the optical fiber data acquisition converter 4 that converts the optical signal into an electrical signal and displays it, The optical fiber data acquisition converter 4 is connected to the monitoring center.

[0021] In this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com