Method for determining bonding firmness of structure adhesive of hidden-frame glass opening window of existing curtain wall and portable detection tool

A technology of existing curtain wall and structural adhesive, which is applied in the field of measuring the bonding fastness of the structural adhesive of the existing curtain wall hidden frame glass opening window and portable detection tools, to achieve the effect of easy displacement, judgment method and logical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

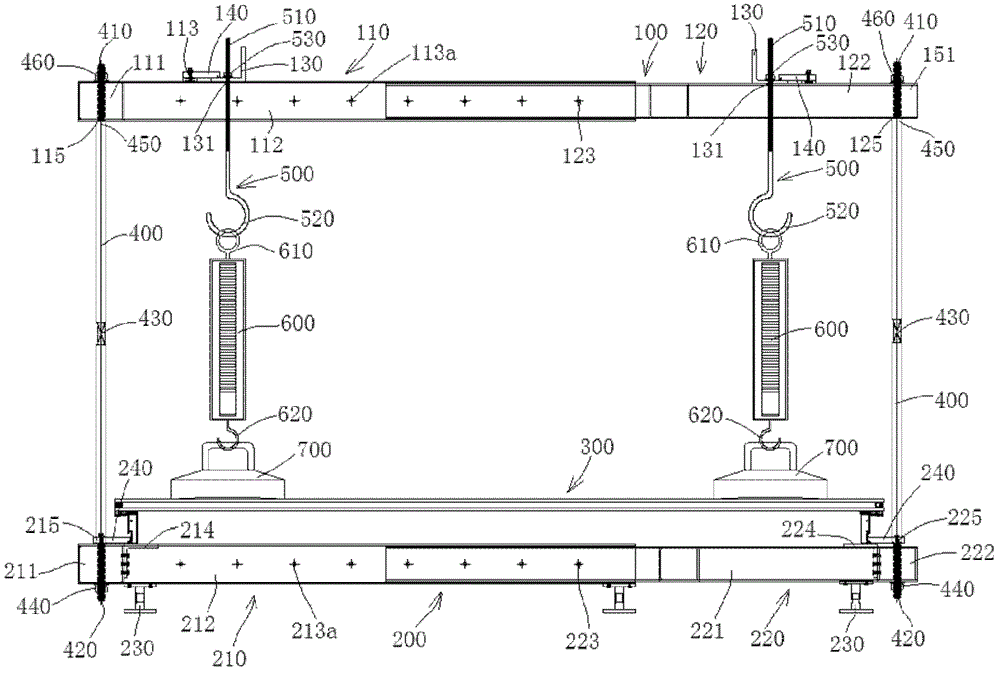

[0037] see figure 1 , the figure shows a portable testing tool for measuring the bonding fastness of the structural adhesive of the existing curtain wall hidden frame glass opening window. The portable testing tool has an upper testing platform 100 and a lower testing platform 200.

[0038] The lower detection platform 200 is mainly used to place and fix the hidden frame glass opening sash 300 to be detected, and the upper detection platform 100 is mainly used to install the steel bolt hook 500 and the force measuring element. The window sash 300 has different sizes, so in this embodiment, the upper and lower detection platforms 100, 200 are made into telescopic lower detection platforms and upper detection platforms that can be stretched vertically and horizontally.

[0039]The specific manufacturing method of the lower detection platform 200 is: the lower detection platform 200 is assembled by using a pair of corner fittings 210 in an L-shaped structure and a corner fitting ...

Embodiment 2

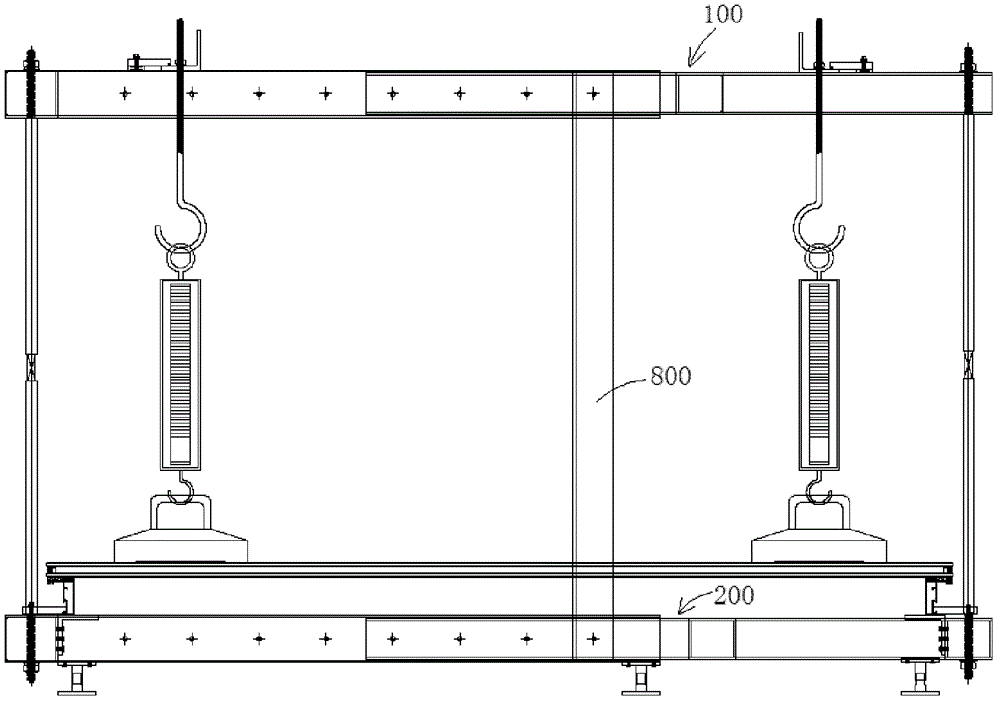

[0054] see figure 2 , the figure shows the portable detection tool for measuring the bond fastness of the existing curtain wall hidden frame glass opening window structure and the use method is basically the same as the portable detection tool provided in Example 1, except that the upper and lower detection platforms A side support element 800 made of 60*6 angle aluminum is connected between the middle positions of the front and rear sides of 100 and 200 to increase the rigidity of the upper detection platform 100 .

Embodiment 3

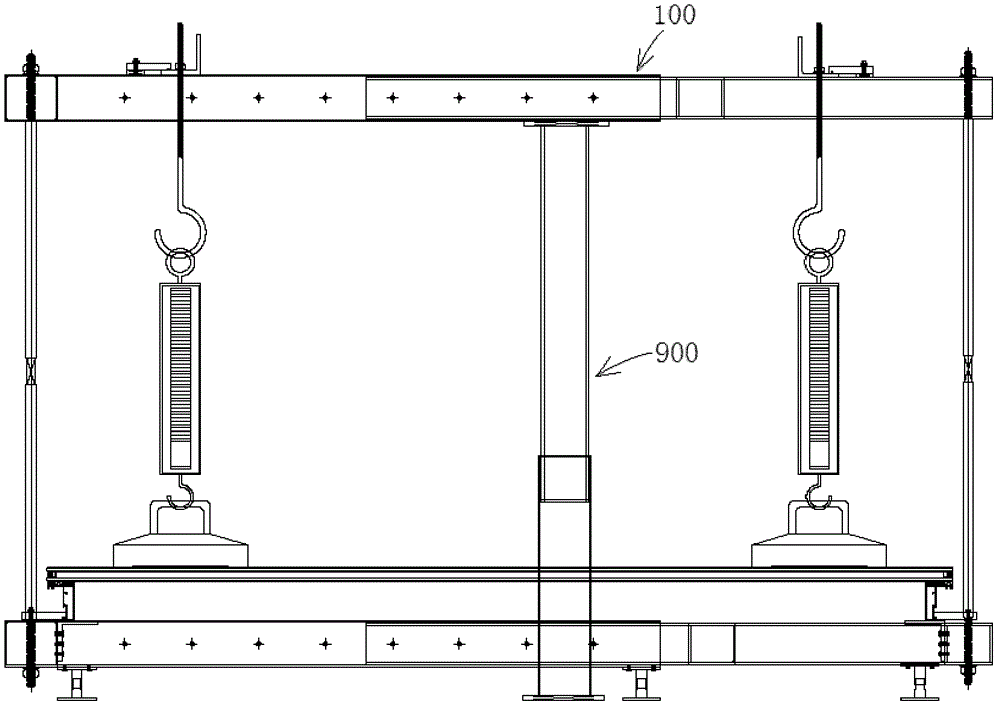

[0056] see image 3 In the figure, the portable detection tool for measuring the bond fastness of the existing curtain wall hidden frame glass opening window structure and the use method are basically the same as the portable detection tool provided in Example 1, except that the upper detection platform 100 A telescopic side support element 800 is connected to the middle position of the front and rear sides, and the lower end of the telescopic side support element 900 is supported on the ground.

PUM

| Property | Measurement | Unit |

|---|---|---|

| suction force | aaaaa | aaaaa |

| suction force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com