Electronic paper device

A technology of electronic paper and column electrodes, which is applied in the fields of electrical digital data processing, instruments, calculations, etc., can solve the problems of high cost, complex manufacturing process of TFT pixel electrodes, and difficulty in applying electronic paper displays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

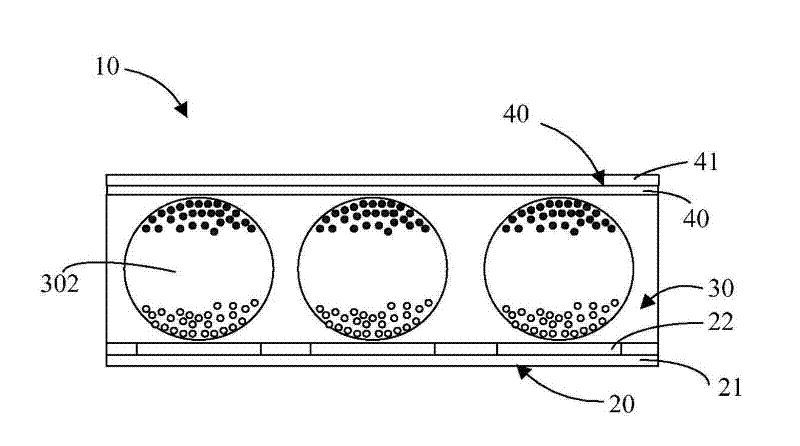

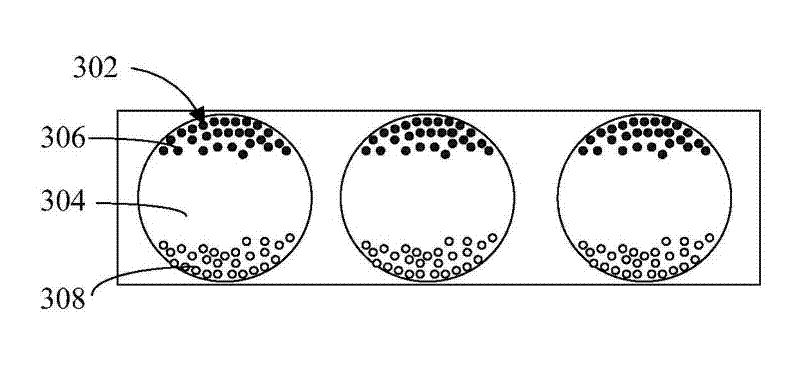

[0019] Please refer to figure 1 , the electronic paper device 10 is a reflective electrophoretic display device, which includes a lower substrate 20 , an electrophoretic display medium layer 30 and an upper substrate 40 . The electrophoretic display medium layer 30 is placed between the lower substrate 20 and the upper substrate 40 . The upper substrate 40 is located on one side of the user's viewing surface.

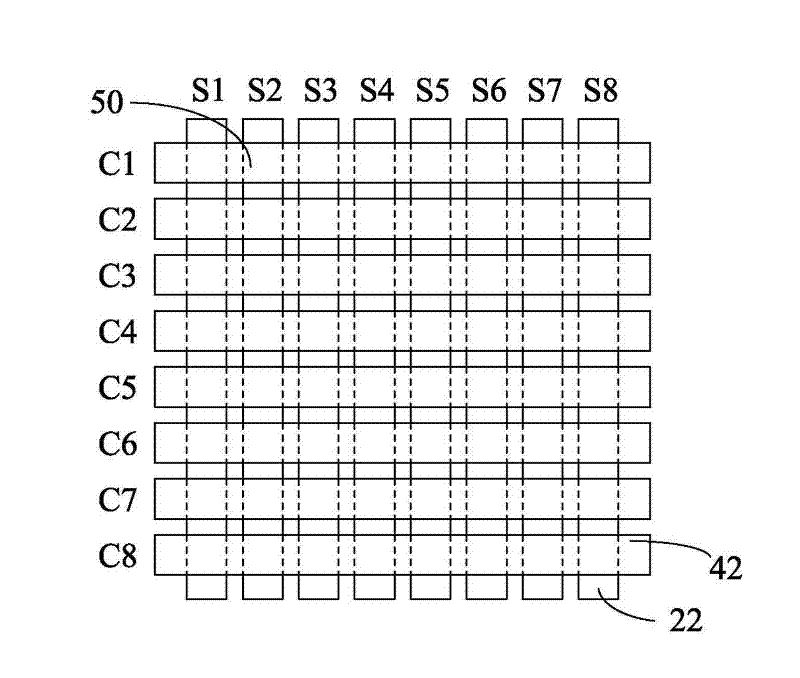

[0020] The lower substrate 20 includes a base 21 and a plurality of row electrodes 22 disposed on the surface of the base 21 close to the electrophoretic display medium layer 30 . The substrate 21 can be a glass substrate, a plastic substrate, a circuit board or a flexible circuit board. A plurality of mutually parallel row electrodes 22 can be formed by chemical etching or thin film printing process on the substrate 21 .

[0021] The upper substrate 40 includes a substrate 41 and a plurality of column electrodes 42, the column electrodes 42 are located between the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com