Brush DC motor

A brushed DC motor and motor housing technology, which is applied in the direction of DC commutators, electrical components, electromechanical devices, etc., can solve the problems of affecting the life of the motor, the weight of the commutation copper sheet, and the large consumables, etc., to meet high requirements. The effect of speed work requirements, improvement of structural firmness, and improvement of heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

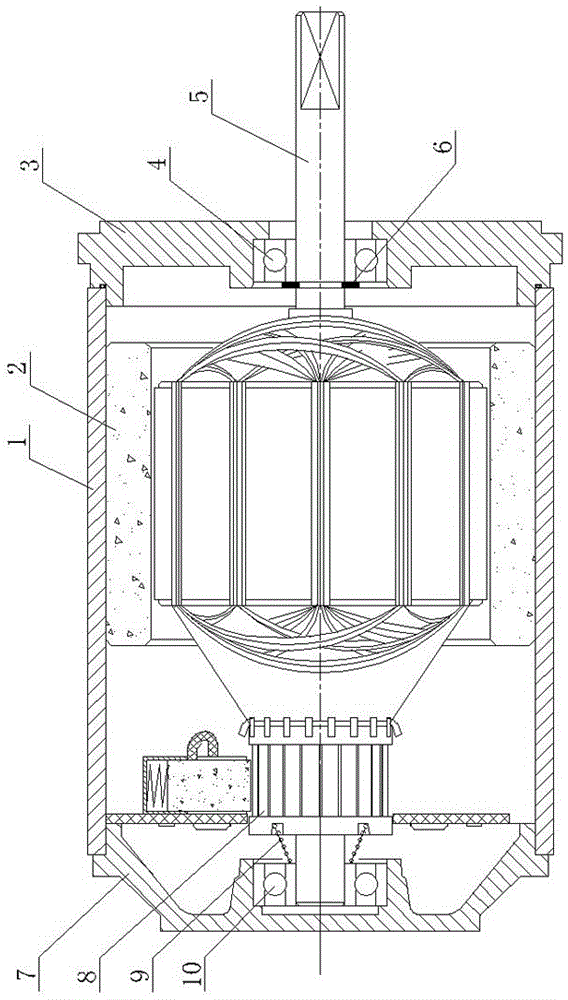

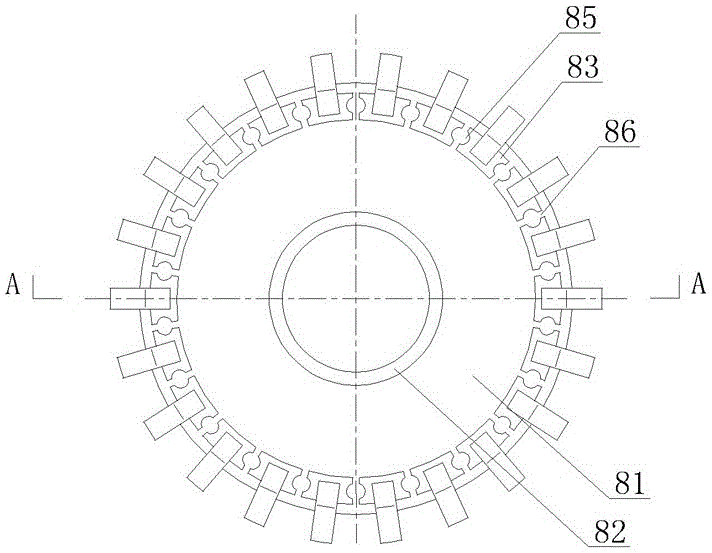

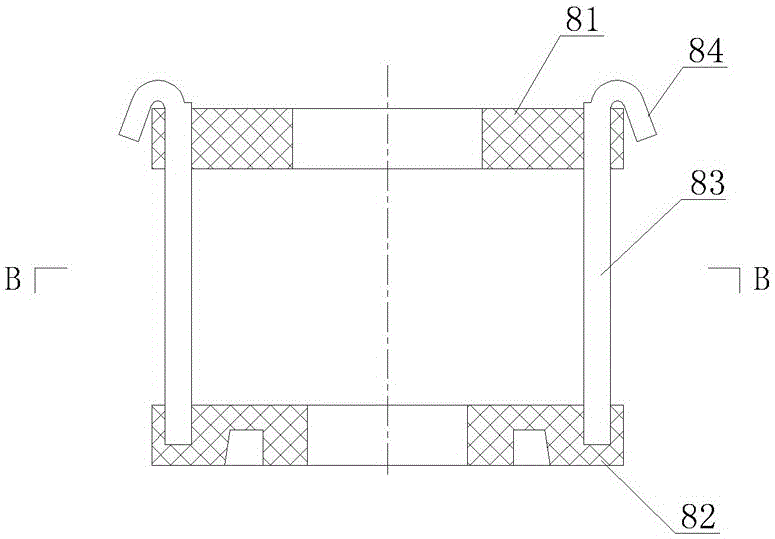

[0016] As shown in the figure, the brushed DC motor of the present invention includes a motor housing 1 and a stator part 2 and a rotor part arranged in the motor housing. The two ends of the motor housing 1 are fixedly connected to the left and right end caps, and the left end cap 7 is provided with a left bearing positioning hole, the left bearing 10 is installed in the left bearing positioning hole, the right end cover 3 is provided with a right bearing positioning hole, and the right bearing 4 is installed in the right bearing positioning hole, and the rotor component includes the rotor shaft 5 and is fixed on the rotor shaft. The commutator 8, the left shaft end of the rotor shaft 5 is slewing supported by the left bearing 10, the right shaft end of the rotor shaft 5 is slewing supported by the right bearing 4, and the right end surface of the outer ring of the right bearing 4 is slewed by the right bearing positioning hole Axially limited by steps, the left end face of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com