Rapid die compensation method considering rebound of bent part

A kind of edge bending and mold technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve the problems of achieving springback angle, uneven distribution of springback on curved edges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] 1. Fit springback distribution function parameters and calculate springback angle

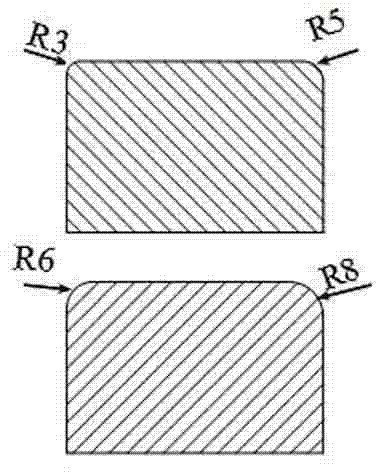

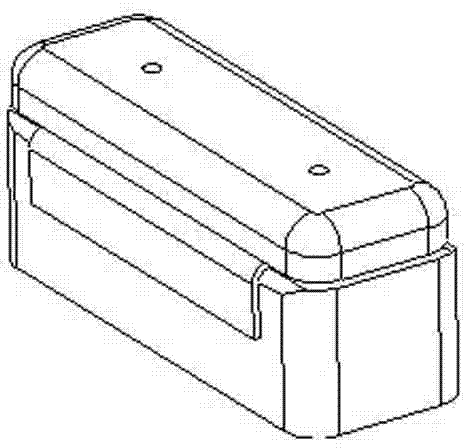

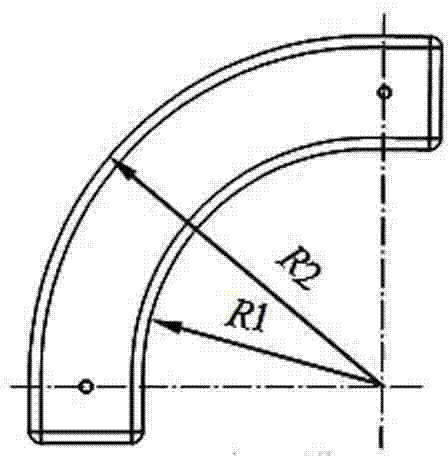

[0087] First of all, the basic bending test is carried out to obtain a series of bending edge springback angle data. The basic flanging test is a series of straight flanging dies (such as Figure 1a , Figure 1b ), curved edge molds with different curvature radii (such as Figure 2a ) and sheets with different arc lengths (such as Figure 2b ) forming test.

[0088] Follow the steps below image 3 As shown in the procedure, the parameters of the rebound distribution function are fitted.

[0089] First, extract the springback angles of the outer and central sides of the curved edge from the springback angle data and , the springback angle of the straight edge , calculated from the rebound angle , value. Secondly, from the geometric parameters of the curved edge corresponding to the test (like Figure 4 shown), transform to get . Finally, the parameters of the springba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com