Reliability, maintainability and supportability (RMS)-oriented planning and design method for line replaceable unit (LRU)

A technology of planning, design and scheme, applied in the field of comprehensive design of performance and maintainability, which can solve the problems of no implementation method, insufficient attention, and insufficient research, so as to improve disconnection, improve maintainability design, and reduce tedious workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

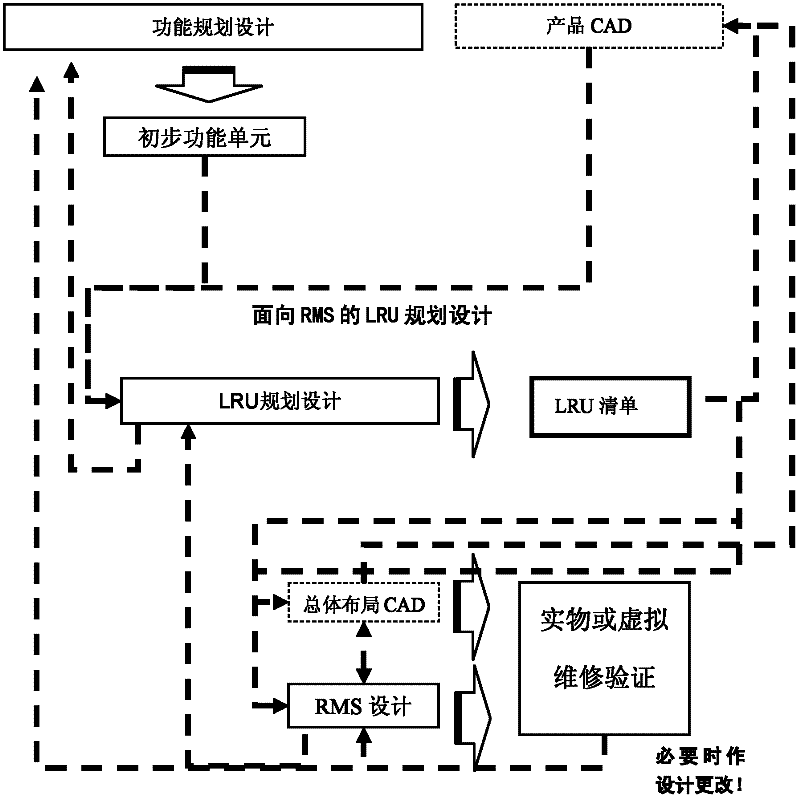

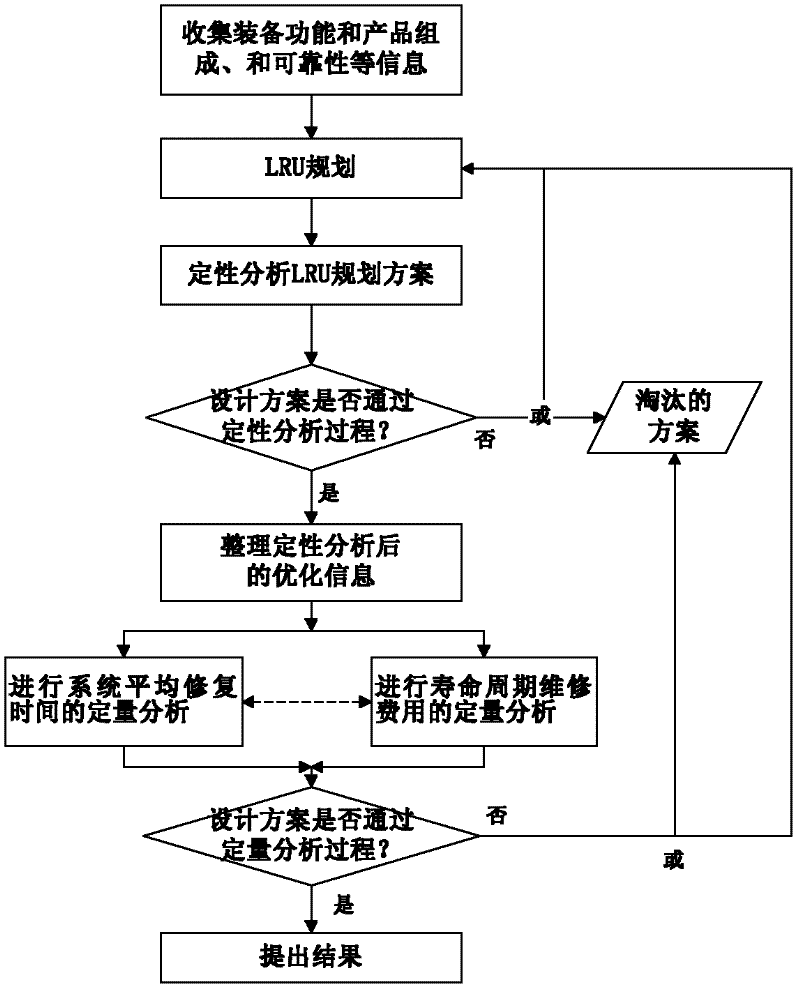

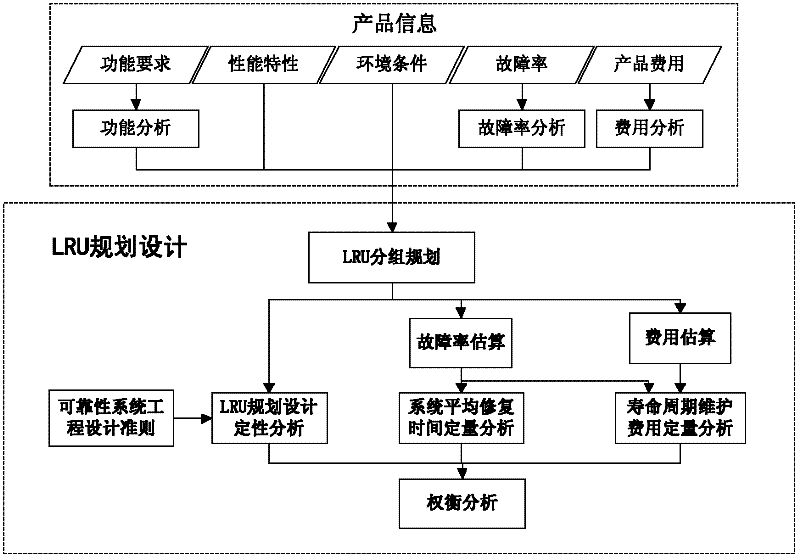

Method used

Image

Examples

Embodiment

[0155] This embodiment is described by taking the chassis and power supply components in the computer as an example.

[0156] Analyzing Objects: Chassis and Power Supplies for Desktop Computers

[0157] Analysis purpose: Determine the LRU division method of the chassis and power supply

[0158] Analysis process:

[0159] Step 1: Collect Information

[0160] It mainly collects information such as the production cost of the chassis and power supply, the failure rate, the use environment and its impact on the failure rate, maintenance methods and required tools, and electromagnetic effects.

[0161] Step 2: Preliminary LRU planning

[0162] Based on the collected information, two LRU planning and design schemes are proposed:

[0163] Option 1: Define the chassis and power supply as a whole as a field-replaceable unit

[0164] Option Two: Define Chassis and Power Supply as Standalone Units as Field Replaceable Units

[0165] Step 3: Qualitative analysis of LRU planning and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com