Workshop production plan and scheduling integrated method under cross-workshop cooperation mode

A technology of production planning and collaboration mode, applied in computing, manufacturing computing systems, instruments, etc., and can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0089] This embodiment specifically implements the solution for the integration of production planning and scheduling described in the summary of the invention, and performs test simulation verification on the optimization results.

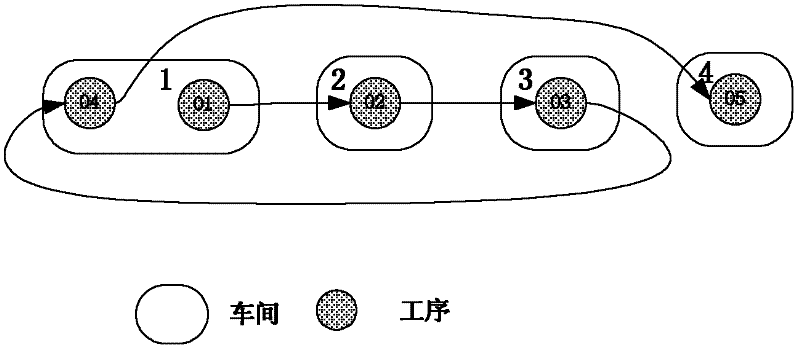

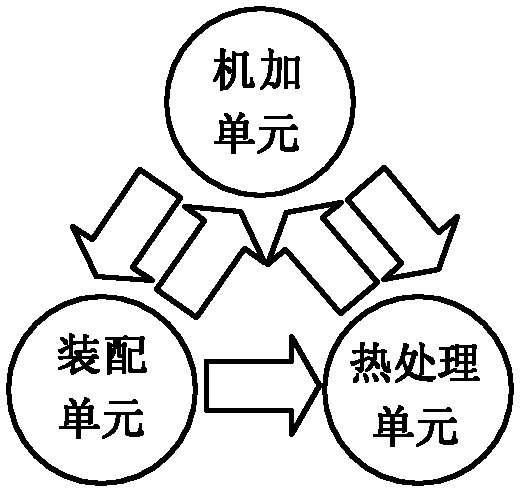

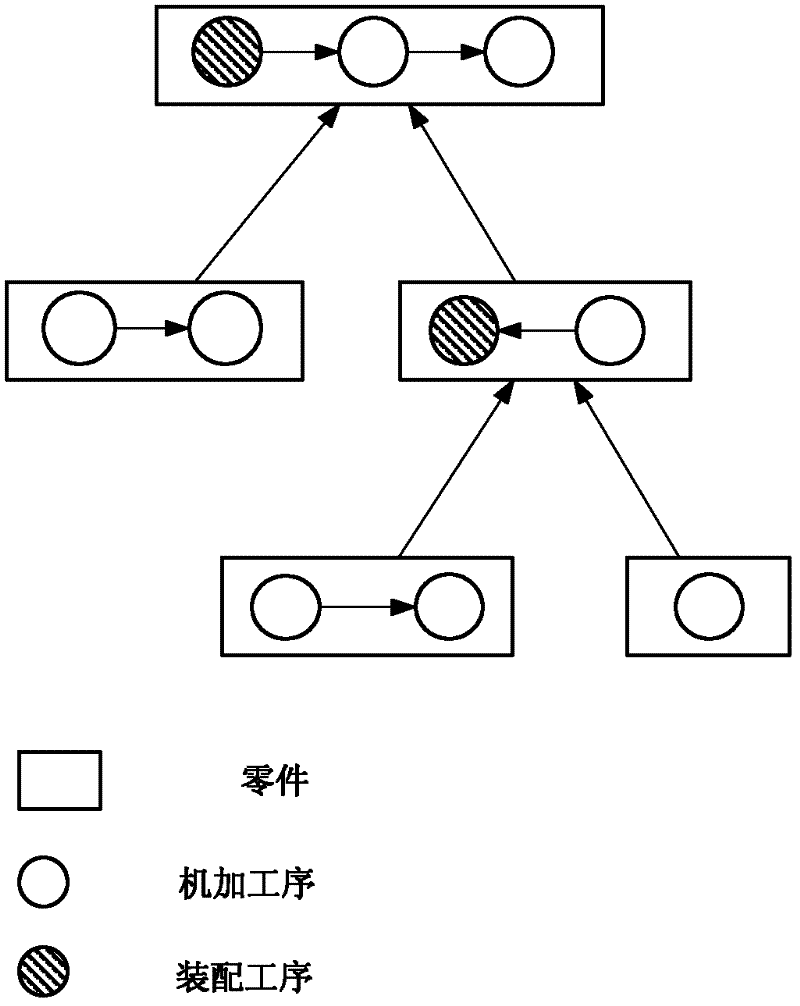

[0090] The flexible manufacturing system used for simulation in this embodiment is set up as follows, with a total of 800 machines distributed in 12 different workshops. These 12 workshops include 3 types of workshops including heat treatment workshop, assembly workshop and machining workshop. The same machine may also be distributed in different workshops. Almost all part routings have shop floor reentrancy issues. The experimental data adopts the data of the actual model A, which contains 2641 parts and 21306 processes.

[0091] Since the maximum production quantity per production month in actual prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com