A kind of preparation method of ultra-thin carbon film

A carbon film and ultra-thin technology, applied in the field of preparation of ultra-thin carbon films, can solve problems such as inapplicability of ultra-thin two-dimensional nanomaterials, and achieve the effects of automatic processing means, simple and efficient preparation methods, and promotion of carbonization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

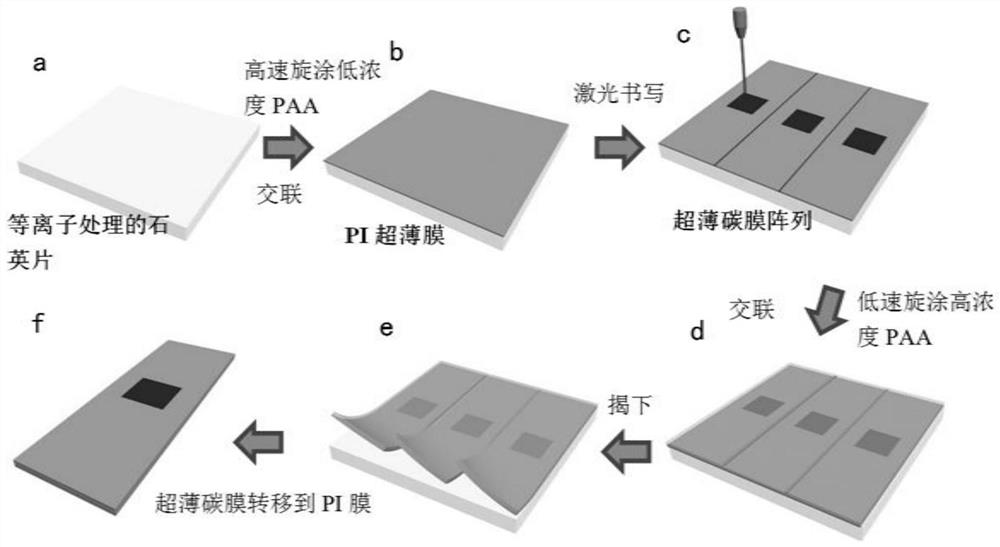

[0046] This embodiment provides a kind of preparation method of ultra-thin carbon film, and its preparation process is as follows figure 1 As shown, the specific operation steps are as follows:

[0047] With quartz as the first matrix material, after the surface is cleaned and dried, plasma treatment is carried out in oxygen for 1 minute to obtain a plasma-treated quartz sheet ( figure 1 a).

[0048]Select polyamic acid solution (PAA), a carbonizable polymer prepolymer, as the carbonization precursor material, dilute the PAA mother liquor to 1wt%, and take an appropriate amount on a quartz plate for high-speed spin coating. The spin coating procedure is as follows: (1) Rotational speed 1000rpm / min, spin coating for 30s, acceleration 500rpm / sec; (2) rotation speed 2000rpm / min, spin coating 30s, acceleration 1000rpm / sec; (3) rotation speed 5000rpm / min, spin coating 30s, acceleration 2000rpm / sec. After spin coating, transfer to an oven for heat treatment as follows: (1) 100°C ...

Embodiment 2

[0052] This embodiment provides a kind of preparation method of ultra-thin carbon film, and its preparation process is as follows figure 1 As shown, the specific operation steps are as follows:

[0053] Quartz is used as the first base material, and after the surface is cleaned and dried, plasma treatment is performed in oxygen for 1 minute to obtain a plasma-treated quartz sheet.

[0054] Select polyamic acid solution (PAA), a carbonizable polymer prepolymer, as the carbonization precursor material, dilute the PAA mother liquor to 7wt%, and take an appropriate amount on a quartz plate for high-speed spin coating. The spin coating procedure is as follows: (1) Rotating speed 1000rpm / min, spin coating for 30s, acceleration 500rpm / sec; (2) rotation speed 2000rpm / min, spin coating 30s, acceleration 1000rpm / sec; (3) rotation speed 5000rpm / min, spin coating 30s, acceleration 2000rpm / sec. After spin coating, transfer to an oven for heat treatment as follows: (1) 100°C for water rem...

Embodiment 3

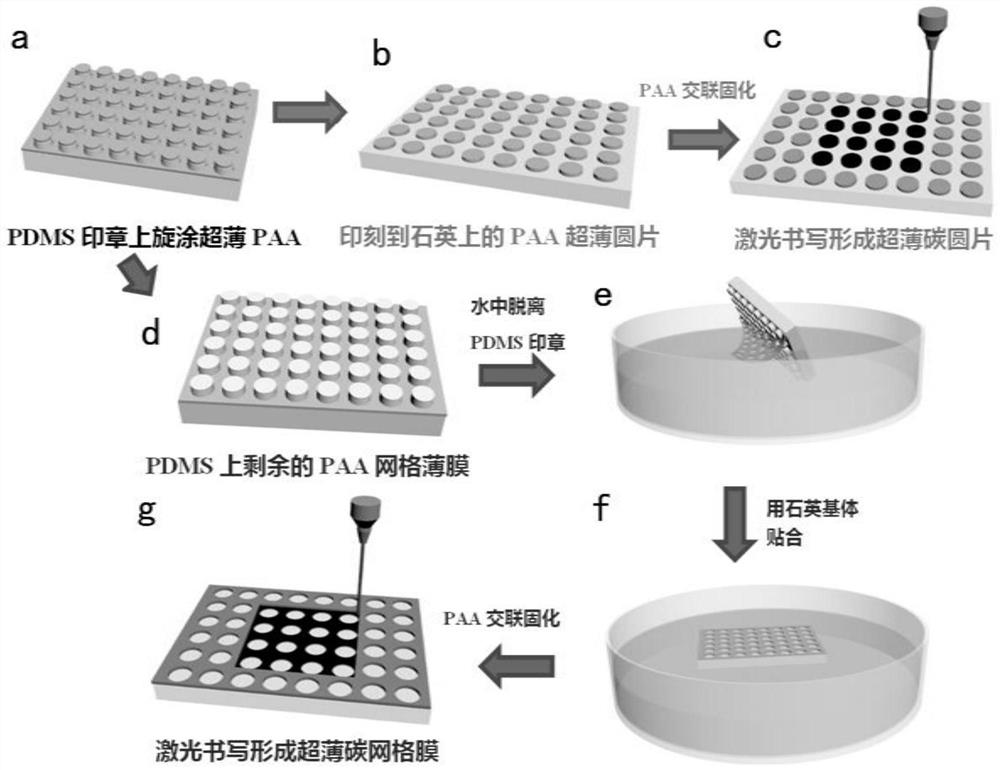

[0060] This embodiment provides a kind of preparation method of ultra-thin carbon film, and its preparation process is as follows figure 2 As shown, quartz is used as the first substrate material; a PDMS disk stamp is used as the second substrate, which is pre-patterned. The specific operation steps are as follows:

[0061] After cleaning and drying the surface of the PDMS stamp, carry out plasma treatment in oxygen for 1 minute, select carbonizable polymer prepolymer polyamic acid solution (PAA) as the carbonization precursor material, dilute the PAA mother liquor to 6wt%, take an appropriate amount of PAA solution in High-speed spin-coating is carried out on the PDMS stamp, and the spin-coating procedure is as follows: (1) 1000rpm / min, spin-coating 30s, acceleration 500rpm / sec; (2) 2000rpm / min, spin-coating 30s, acceleration 1000rpm / sec; (3) The rotating speed is 5000rpm / min, the spin coating is 30s, and the acceleration is 2000rpm / sec. The spin-coated pattern was a circu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com