Lithium-ion secondary battery and positive electrode active material thereof

A positive electrode active material and secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as unsatisfactory power performance and difficult battery charging and discharging process, and achieve the goal of expanding the charging cut-off voltage and improving the direct effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

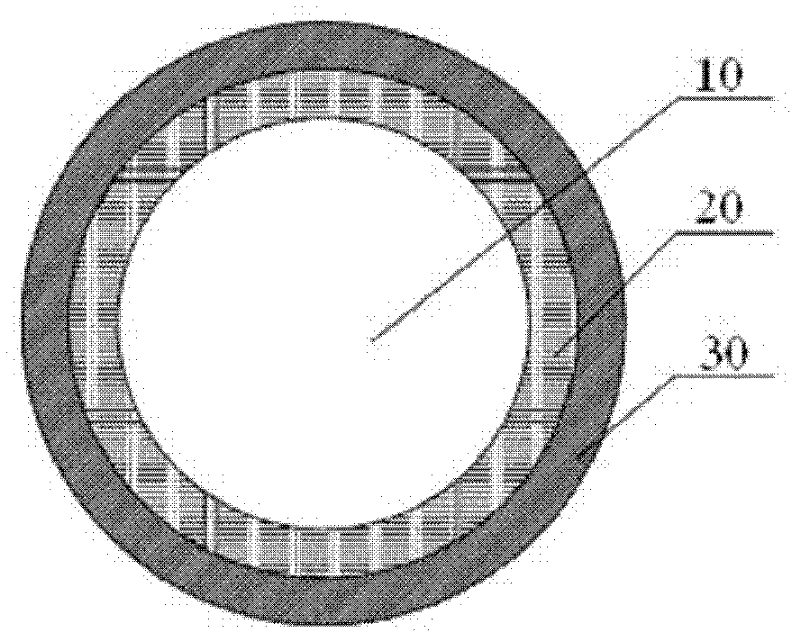

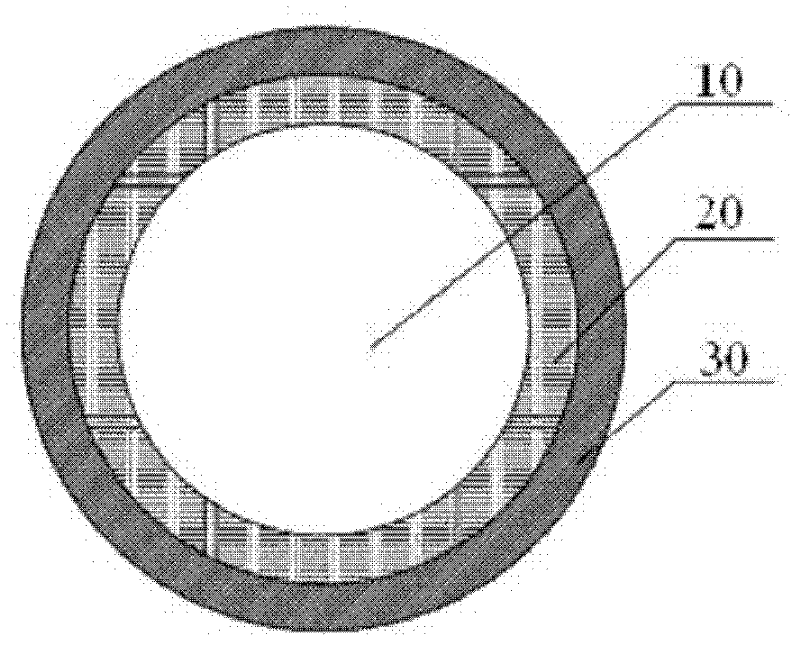

[0033] Example 1: According to the above material synthesis method, a composite lithium-containing metal oxide material with a 3-layer structure was obtained: Al 2 o 3 / Li 1.02 co 0.98 Al 0.02 o 2.01 / LiCoO 2 . According to the above-mentioned production method, a lithium-ion secondary battery with the lithium-containing metal oxide as the positive electrode was prepared, and the BET of the prepared material was measured by a specific surface area meter to be 0.27m 2 / g, the test voltage range of the battery is 3.0-4.6V.

Embodiment 2

[0034] Example 2: According to the above-mentioned material synthesis method, a composite lithium-containing metal oxide material with a 3-layer structure: TiO 2 / Li 1.01 co 0.98 Al 0.01 o 2.01 / LiCoO 2 . According to the above-mentioned production method, a lithium-ion secondary battery with the lithium-containing metal oxide as the positive electrode was prepared, and the BET of the prepared material was measured by a specific surface area meter to be 0.18m 2 / g, the test voltage range of the battery is 3.0-4.6V.

Embodiment 3

[0035] Example 3: According to the above-mentioned material synthesis method, a composite lithium-containing metal oxide material with a 3-layer structure was obtained: ZrO 2 / Li 0.99 co 0.98 Al 0.02 o 2.01 / LiCoO 2 . According to the above-mentioned production method, a lithium-ion secondary battery with the lithium-containing metal oxide as the positive electrode was prepared, and the BET of the prepared material was measured by a specific surface area meter to be 0.22m 2 / g, the test voltage range of the battery is 3.0-4.6V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com