Electric connector with wire-stranding elastic contact pin

A technology of elastic pins and electrical connectors, applied in the direction of contact parts, etc., can solve the problem that the parameters cannot be selected arbitrarily, and achieve the effect of increasing the effective contact area, reducing the insertion force and improving electrical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

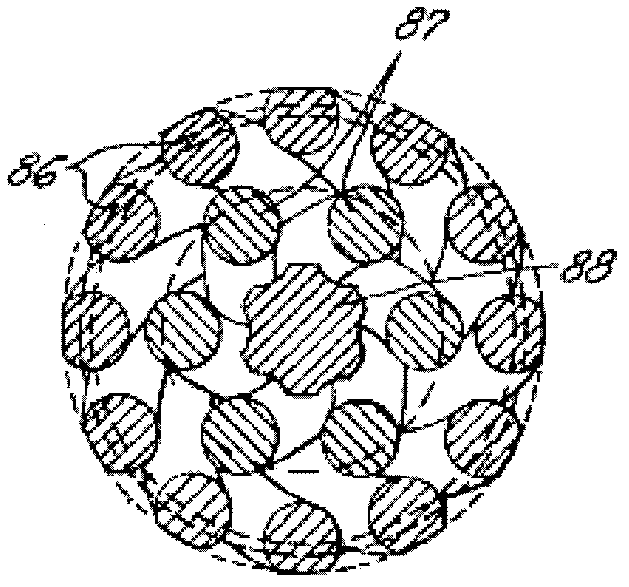

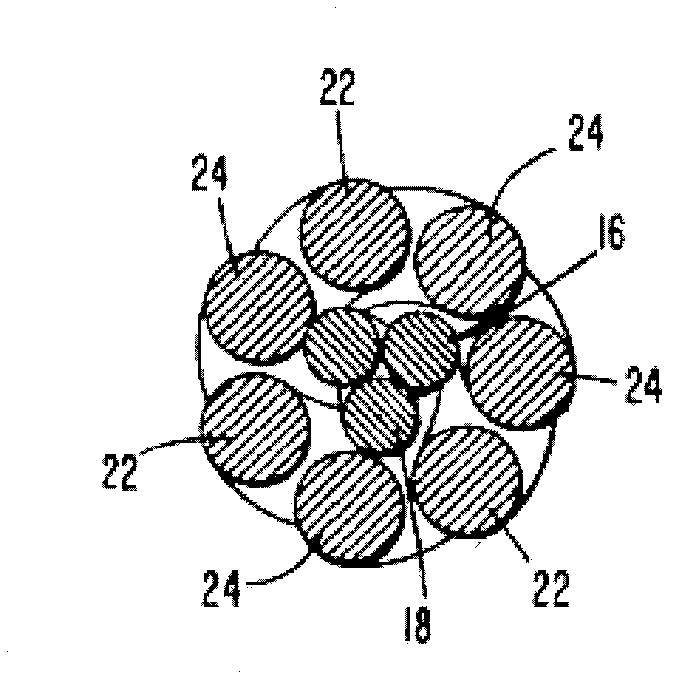

Method used

Image

Examples

Example

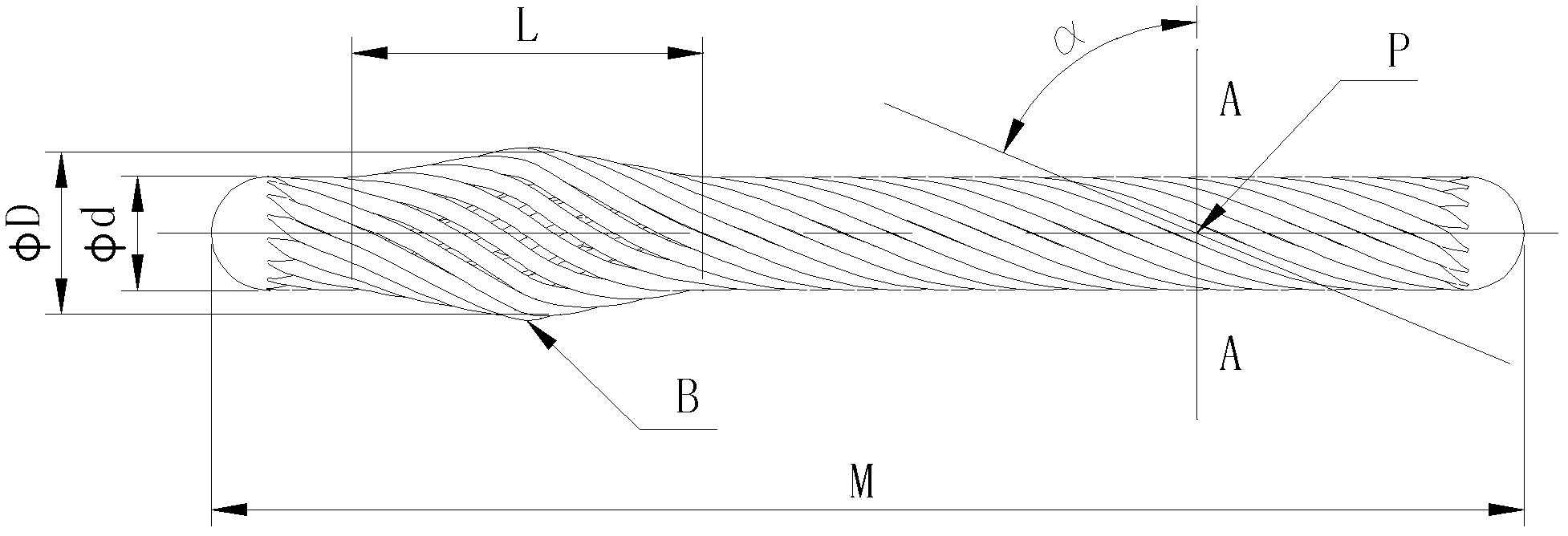

[0046] Comparative example and test example

[0047] Change the needle diameter d to The stranded elastic pin and the traditional inner layer of 3 beryllium bronze wires and the outer layer of 7 beryllium bronze wires are applied to a 100-core connector, respectively. Test verification, under the same conditions as the test sleeve and other conditions, the test results of the connector engagement force, connector separation force, contact separation force (that is, the pin separation force), and the number of plug life cycles are shown in the table 1 shows:

[0048] Table 1 The connector using the pin of the present invention and the connector using the traditional pin

[0049] Test verification data comparison table

[0050]

[0051] Note: The 500-times life of the connector with traditional pins is the data required by GJB2446-95 "General Specification for Shell Positioning Ultra-small Rectangular Electrical Connectors".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com