Windscreen wiper apparatus

A wiper and glass technology, applied in transportation and packaging, vehicle cleaning, vehicle maintenance, etc., can solve the problems of increased force, difficulty, and increased risk of unmeasured force, and achieve the effect of reduced forced deformation and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

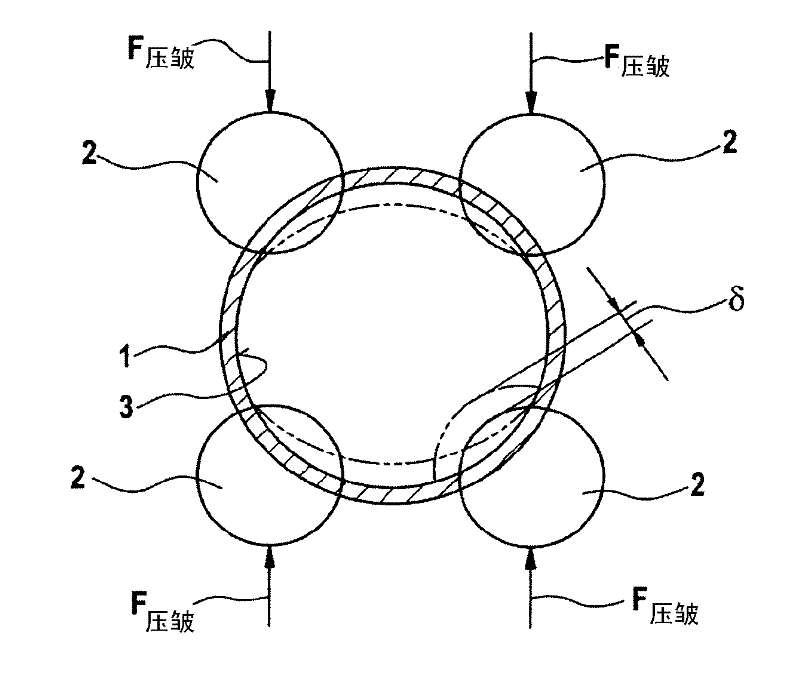

[0036] figure 1 A tubular carrier 1 for a windshield wiper system of a motor vehicle, not shown in detail, is shown in a schematic cross-sectional illustration.

[0037] Arranged on the tubular support part 1 is a crimping tool which comprises four crimping punches 2 . The crimping punch 2 is arranged such that the springback is adapted to the deformation of the circular cross-section of the tubular support part 1 caused by crimping, ie the springback δ and the deformation are minimized.

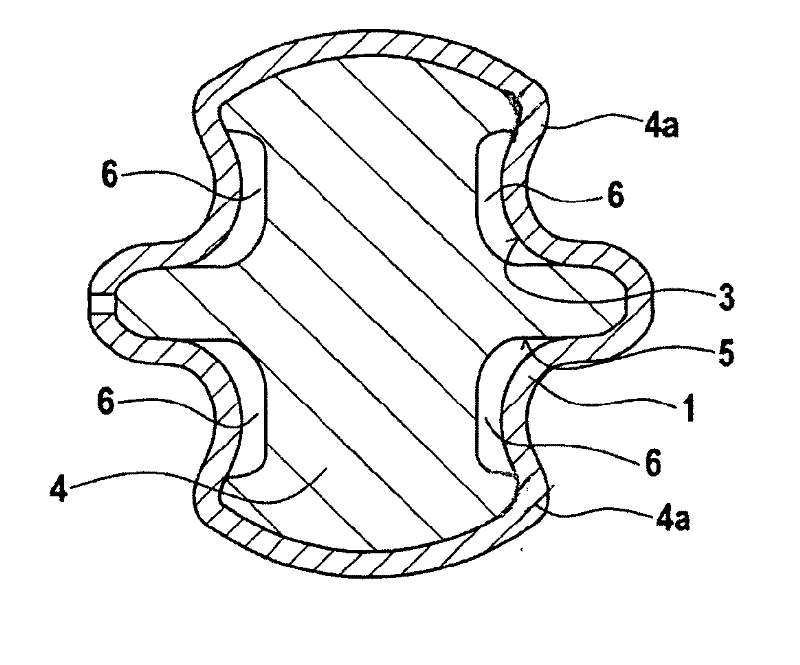

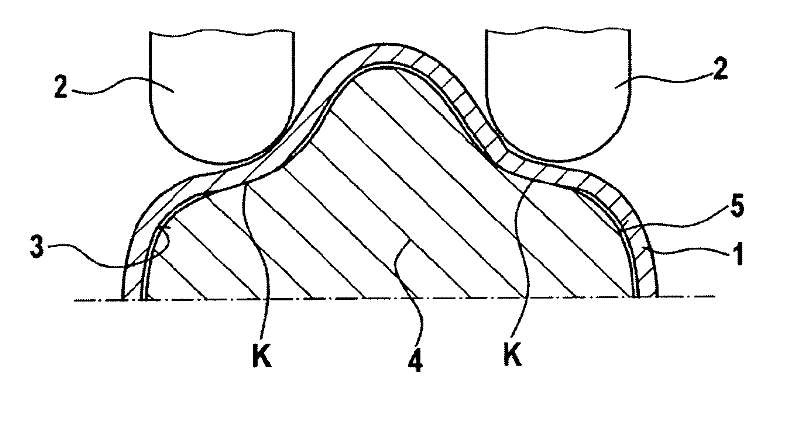

[0038] The tubular support part 1 has a circular cross-section in its initial shape, which has an inner contour 3 which, by exerting a force F on the crimping punch 2 压皱 deform locally, thus making it appear after the creasing process as figure 2 the shape shown. according to the existing technology figure 1 and 2 A bearing pin is accommodated in a tubular carrier part 1 whose cross section is substantially circular and whose outer contour essentially follows the inner contour 3 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com