Brake system and method for setting a braking torque of such a brake system

A technology of braking equipment and braking torque, applied in the direction of brakes, mechanical equipment, braking components, etc., can solve problems such as failure, increased wear of reducers, loss of comfort, etc., and achieve the effect of reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

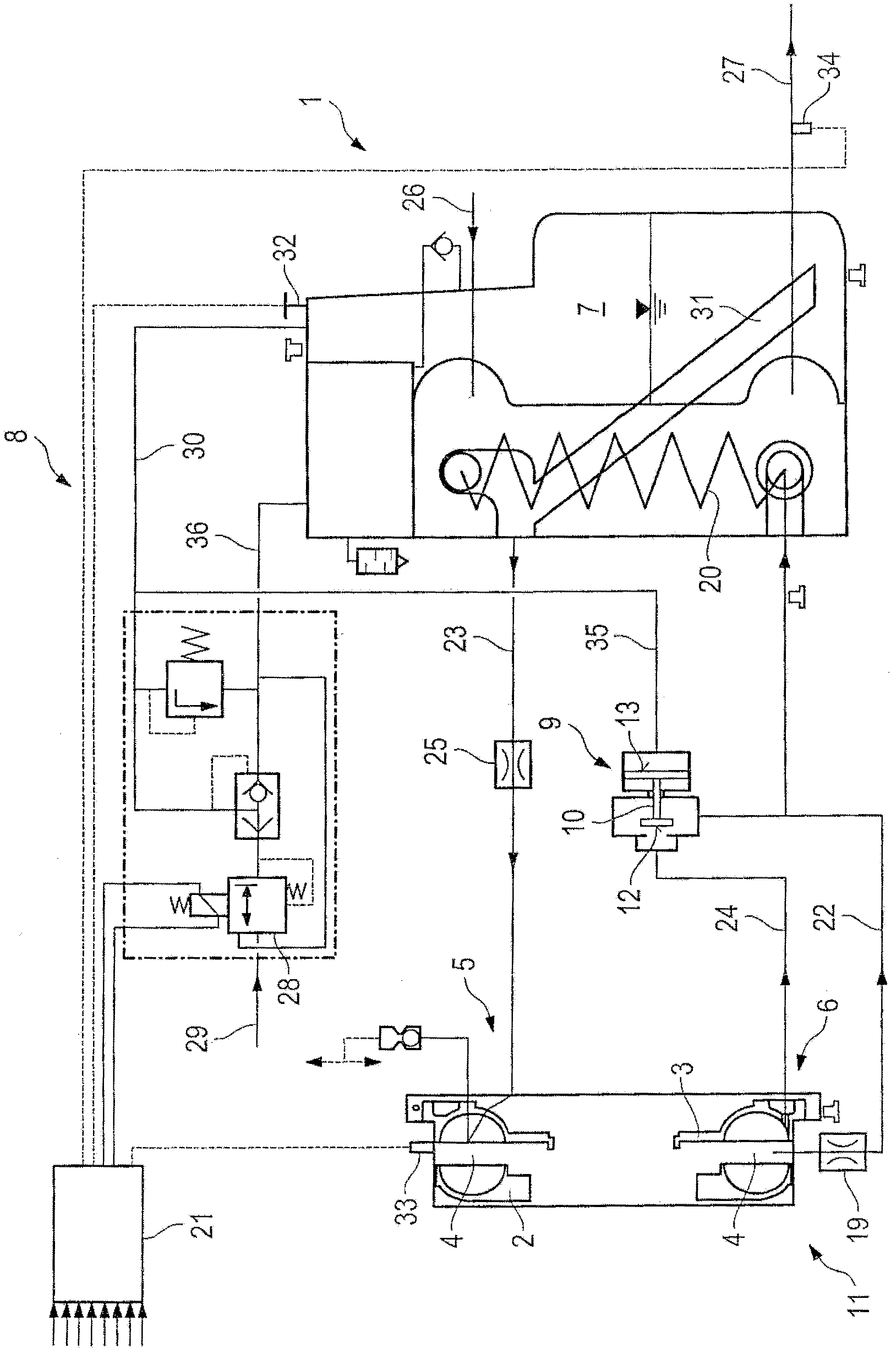

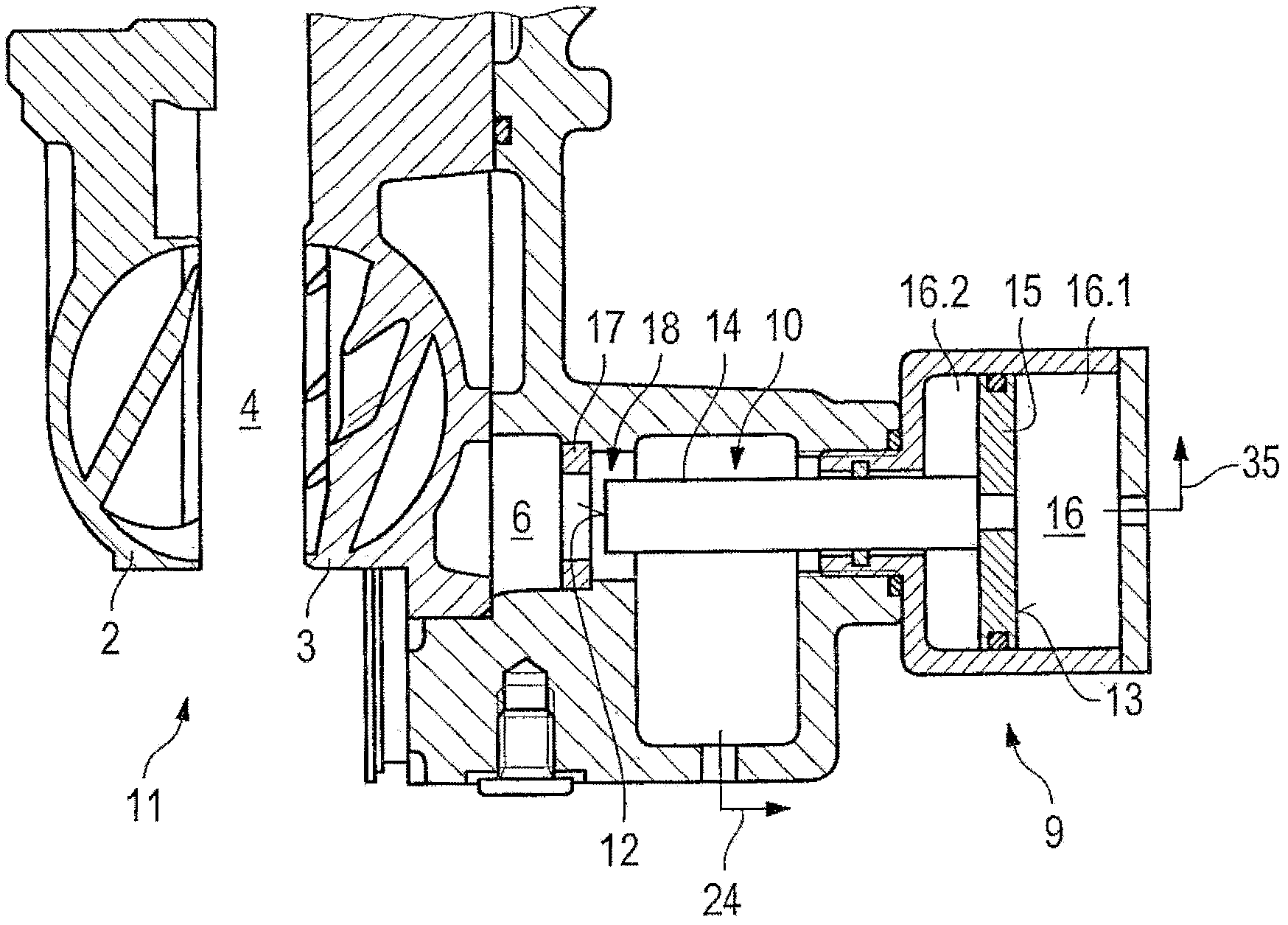

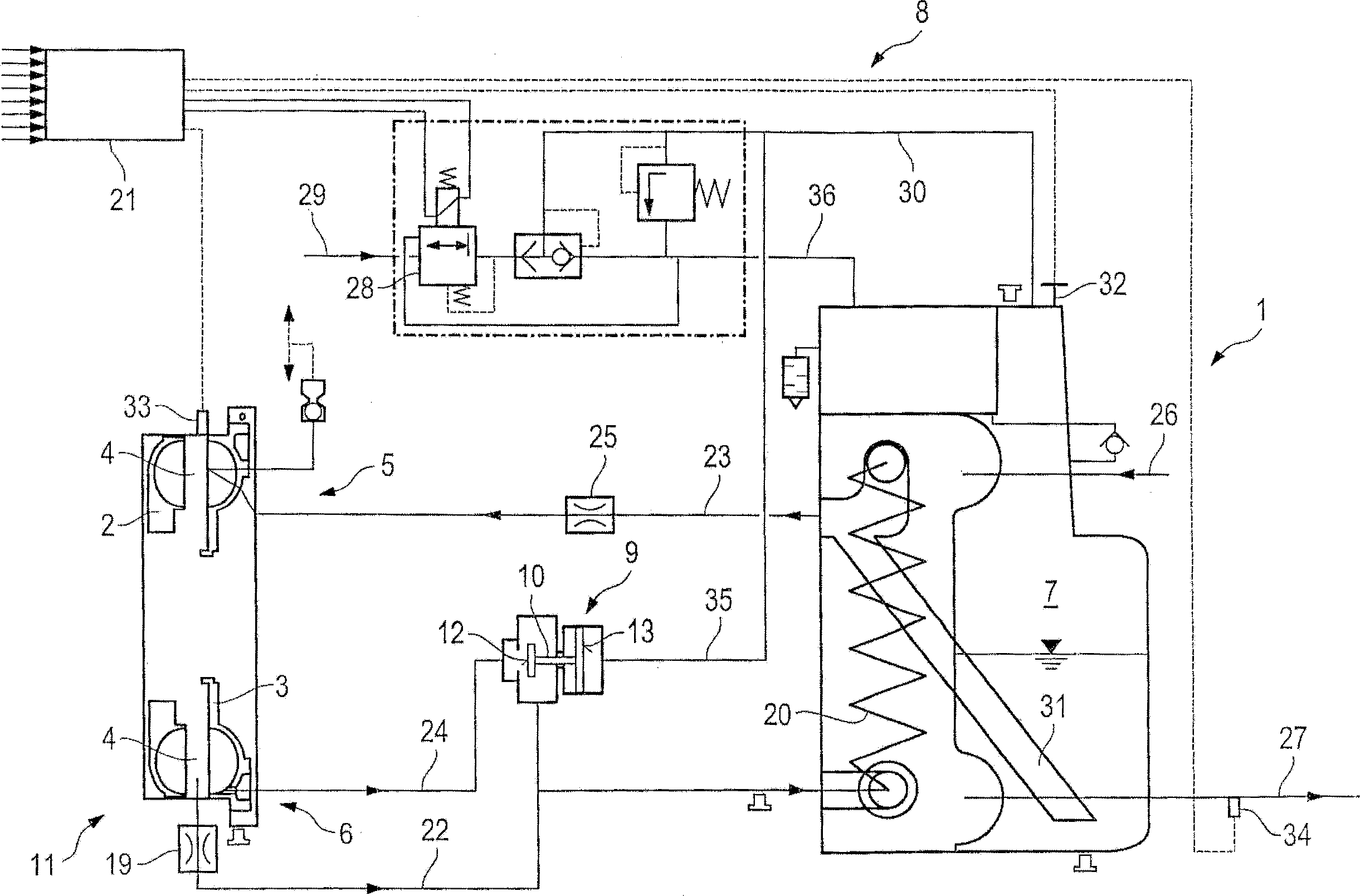

[0030] exist figure 1 shows a brake system of a vehicle with an external working medium circuit 1 conducting the working medium. In the working medium circuit 1, the following components are arranged one after the other in the flow direction: a hydraulic reducer 11, including a rotor 2 and a stator 3, and the rotor and the stator together form a torus-shaped working chamber 4; An opening of the connecting line 22 to the first working medium cooler 20 , wherein the working medium oil is also referred to as an oil cooler; a fixed restrictor 19 of constant cross-section arranged in the first connecting line 22 ; A working medium cooler 20 ; an opening of a second connecting line 23 from the working medium cooler 20 to the working chamber 4 of the hydrodynamic retarder 11 ; and a further throttle 25 . Here, the second connecting line 23 opens into the inlet 5 , through which the working chamber 4 can be filled with working medium from the first connecting line 23 of the external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com