Fuel flowmeter having an improved control device

A technology of fuel flow and flow meter, which is applied in the fuel valve of turbine/propulsion device, fuel control of turbine/propulsion device, jet propulsion device, etc., and can solve problems such as engine speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

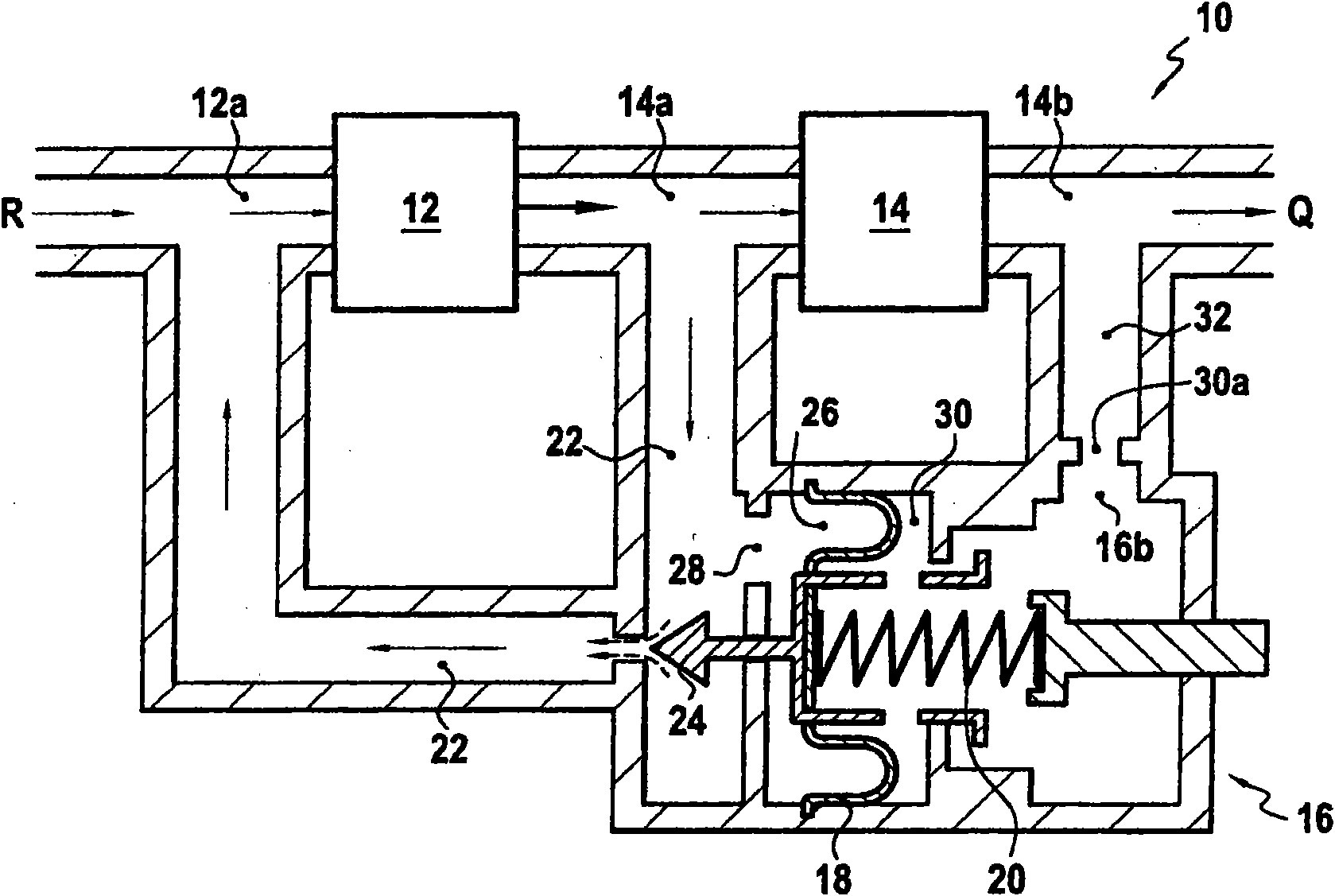

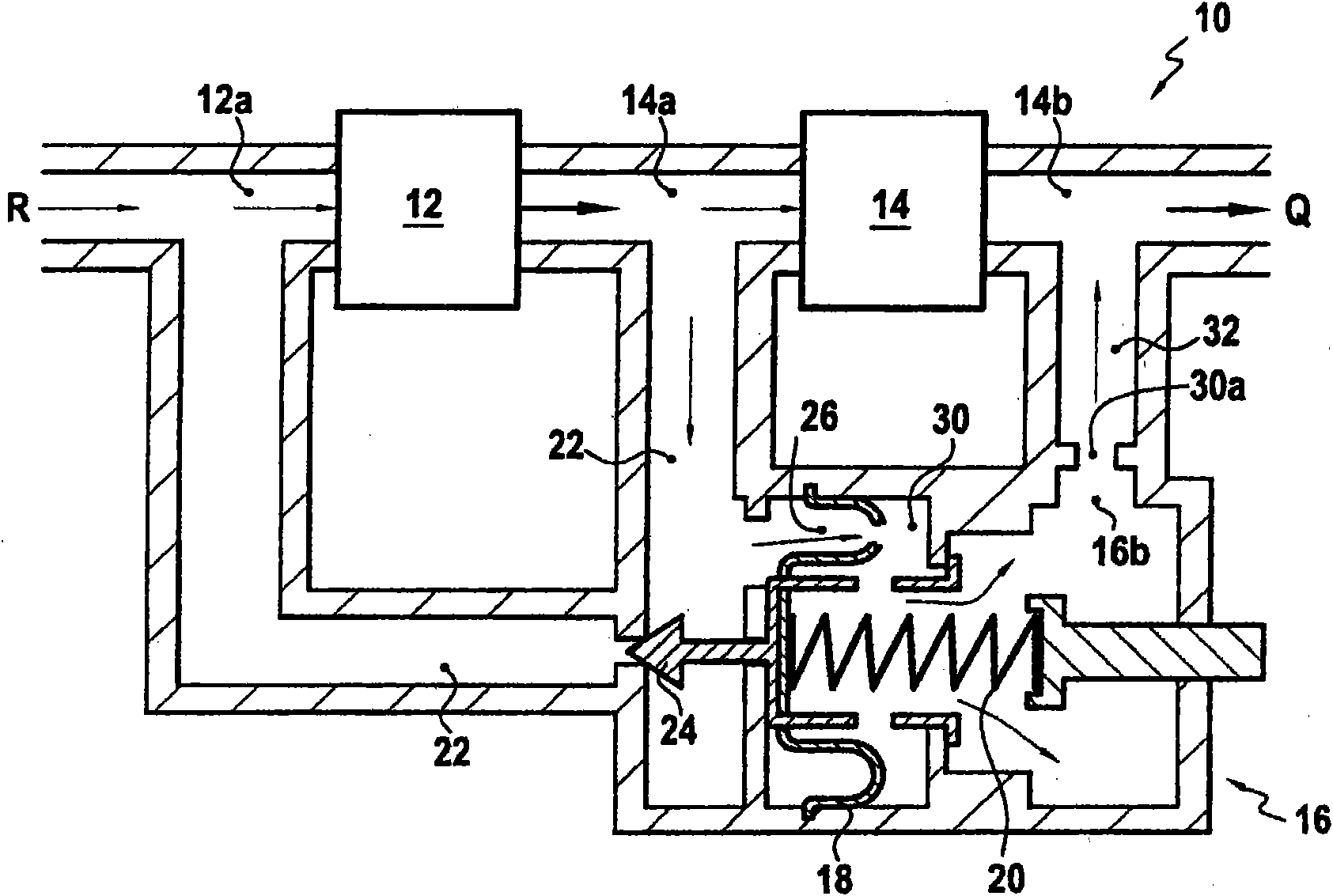

[0041] Figure 1, which shows a prior art fuel flow meter, has been described in the background section of the above specification. It should be noted that the pump is connected to the fuel tank R, and the regulator device 16 has a first chamber 26 in communication with the circuit 22 . This communication is preferably through an opening 28 formed upstream of the valve member 24 .

[0042] In normal operation, this first chamber is delimited in particular by a detection surface 18 , in particular a flexible diaphragm, such that the pressure in the first chamber is equal to the pressure at the inlet 14a of the metering valve 14 .

[0043] The prior art regulator device also includes a second chamber defined by the partition 18 and communicating with an outlet circuit 32 connecting the outlet 16b of the regulator device with the outlet 14b of the metering valve 14 . It can therefore be understood that the fuel pressure in the second chamber is equal to the pressure at the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com