Method for controlling tobacco flavoring/feeding proportion precision

A technology of feeding ratio and precision control, applied in tobacco, tobacco preparation, application, etc., can solve problems such as untimely adjustment, low product quality, and low production efficiency, so as to improve production efficiency, shorten adjustment time, and avoid unqualified products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

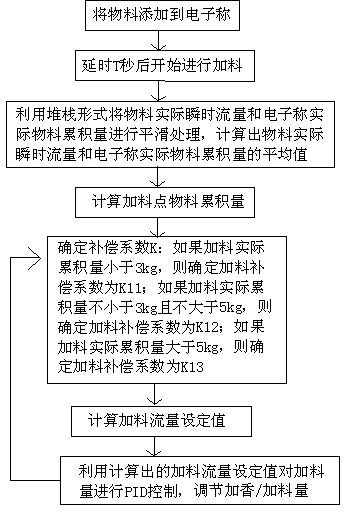

[0021] When using the tobacco flavoring / feeding ratio precision control method of the present invention, the central control selection operation of the existing flavoring / feeding compensation function can be canceled first, and the real-time automatic compensation function of the method according to the present invention can be realized through PID automatic adjustment . Such as figure 1 Shown, the present invention comprises the following steps:

[0022] The first step is to add materials to the electronic scale;

[0023] The second step is to start feeding after a delay of T seconds, and accurately measure the time T from when there is material on the electronic scale to when the processing equipment starts feeding;

[0024] The third step is to use the stack form to smooth the actual instantaneous flow of materials and the actual material accumulation of electronic scales, and calculate the average value of the actual instantaneous flow of materials and the actual accumul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com