Machine capable of washing dishes separately

A washing machine and tableware technology, applied in the field of kitchen cleaning, can solve the problems of high maintenance rate, waste of water, time and electricity, complex design structure, etc., and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

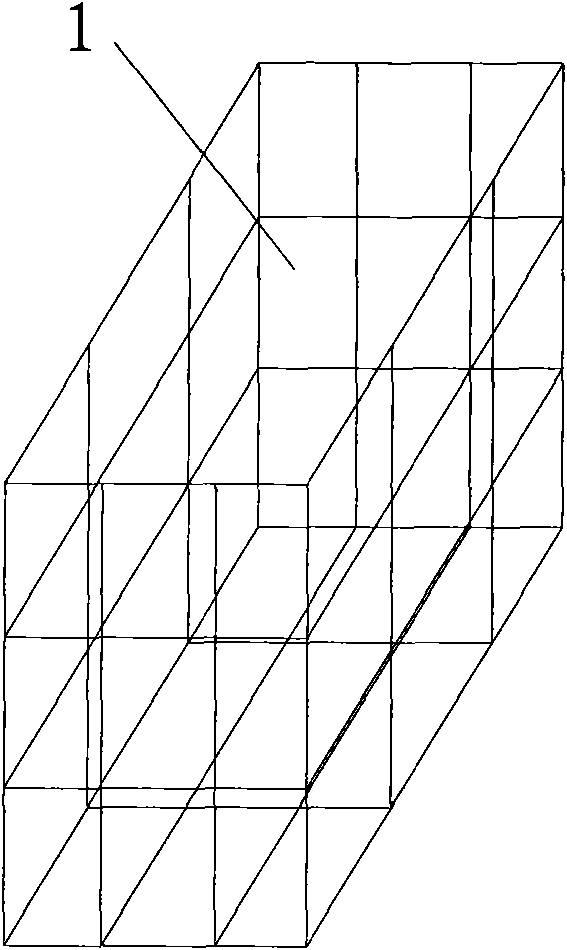

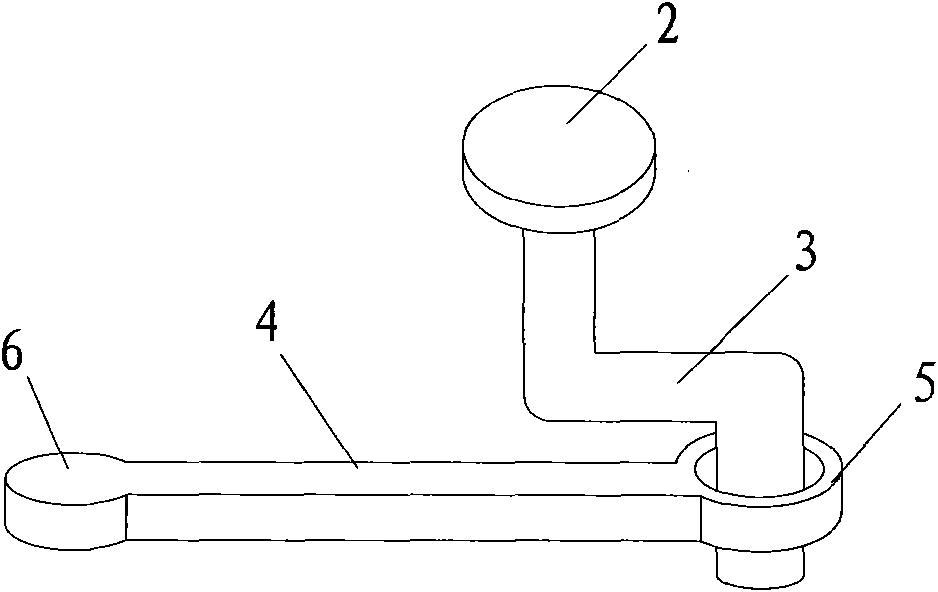

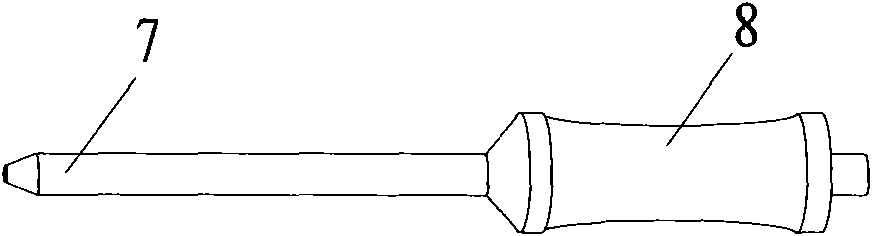

[0061] Single tableware washing machine of circular structure (the rotating device is a curved rod structure), see Figure 1 to Figure 8 .

[0062] Design the cutlery rack as a single cutlery slot, see figure 1 shown. Design the rotating device as a bent rod structure, see figure 2 . Sprinklers designed as spray guns, see image 3 Shown; the dishwashing cavity is designed as a circular structure, see Figure 4 . Put the tableware in the slot, rotating device, spray gun, and dishwashing cavity according to the Figure 5 to Figure 8 Shown is a single dishwashing machine installed in a circular configuration. In order to facilitate the intuitive tableware cleaning process, it is suggested that the material of the dishwashing cavity 10 is preferably transparent glass fiber reinforced plastic. The length, width and height of the tableware single storage slot 1 are preferably 30cmX10cmX20cm, and the material is preferably stainless steel bars, and the grid size is recommend...

Embodiment 2

[0066] Single tableware washing machine with square structure (rotating device is motor-controlled structure), see Figure 10 to Figure 12 .

[0067] Design the cutlery rack as a single cutlery slot, see figure 1 shown. Design the rotary device as an electric rotary device structure, see Figure 10 . Sprinklers designed as spray guns, see image 3 Shown; the dishwashing cavity is designed as a square structure, see Figure 11 . Put the tableware into the slot, the electric rotating device, the spray gun, and the dishwashing cavity according to the Figure 11 to Figure 12 Shown is a single dishwashing machine installed in a square configuration.

[0068] The working characteristics of the electric rotating device: every time the button on the motor control device 24 is pressed, the riser 2 will rotate half a circle. If the initial state of the single tableware slot 1 is that a longer side is facing the spray gun inlet, then the motor 23 is started once, and the single t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com