Automatic grinding and polishing system of crystal blank

A technology for blanks and crystals, applied in the field of automatic grinding and polishing systems for crystal blanks, can solve the problems of difficult mechanism layout, high requirements on machine manufacturing precision, difficult manufacturing and transportation, etc., so as to reduce machine energy consumption and material manufacturing costs, The effect of simplifying the transfer and circulation mode of the fixture and simplifying the complexity of the mechanism action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

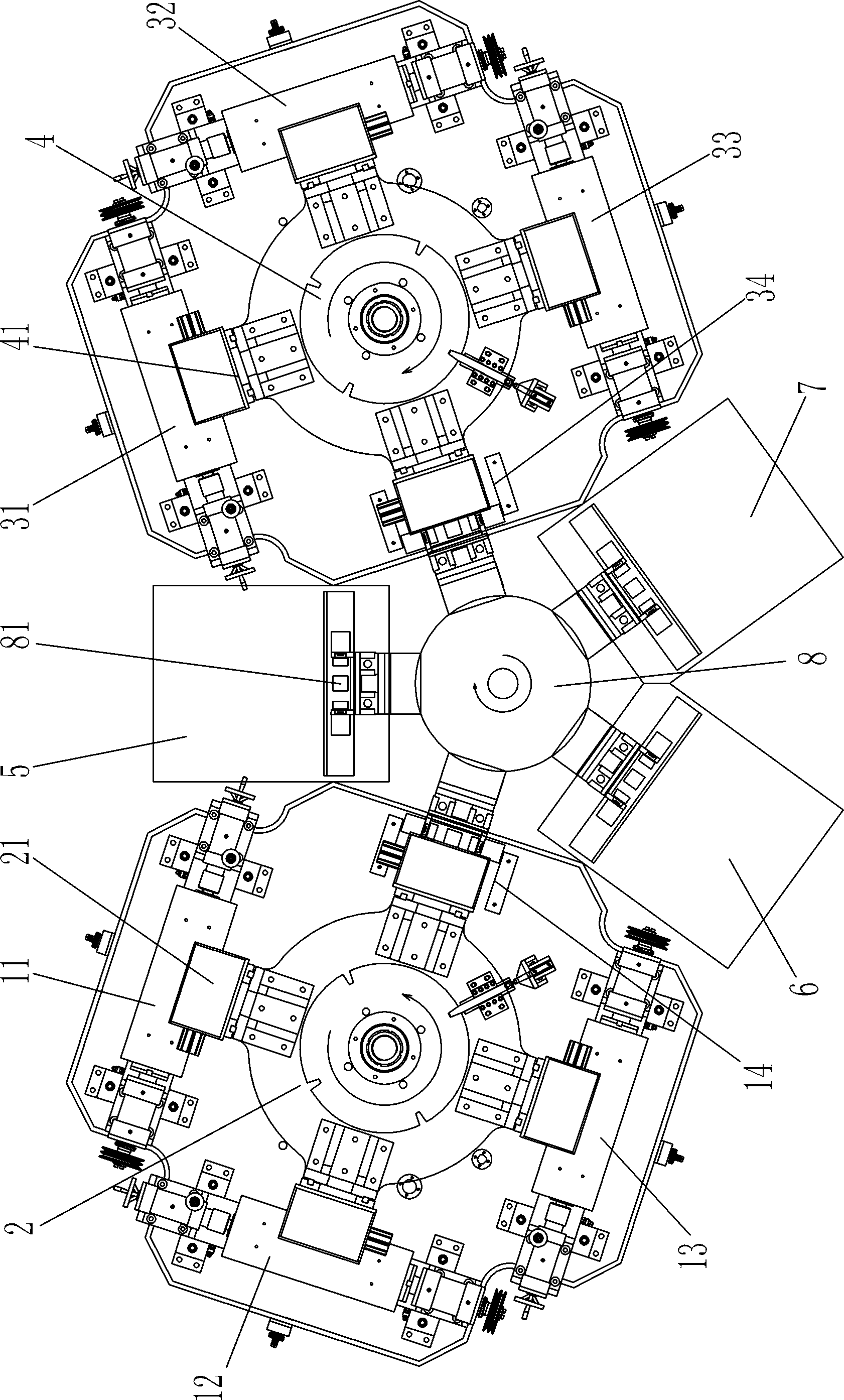

[0024] like figure 1 The shown automatic grinding and polishing system for crystal blanks includes: a first rotating frame 2, around the first rotating frame 2, there are two upper hemisphere grinding stations 11 for grinding the upper hemisphere of the crystal blank. , 12 and an upper hemisphere polishing station 13 for polishing the upper hemisphere of the crystal blank, a waiting station 14, the first rotating frame 2 can be rotated and positioned and is provided with four heads 21; The second rotating frame 4. There are two lower hemisphere grinding stations 31 and 32 for grinding the lower hemisphere of the crystal blank and a lower hemisphere polisher for polishing the lower hemisphere of the crystal blank around the second rotating frame 4. Position 33, a waiting station 34, the second rotating frame 4 can be rotated and positioned and is provided with four machine heads 41; the feeding station 6 is provided with a feeding mechanism that can fix the crystal blank on the...

Embodiment 2

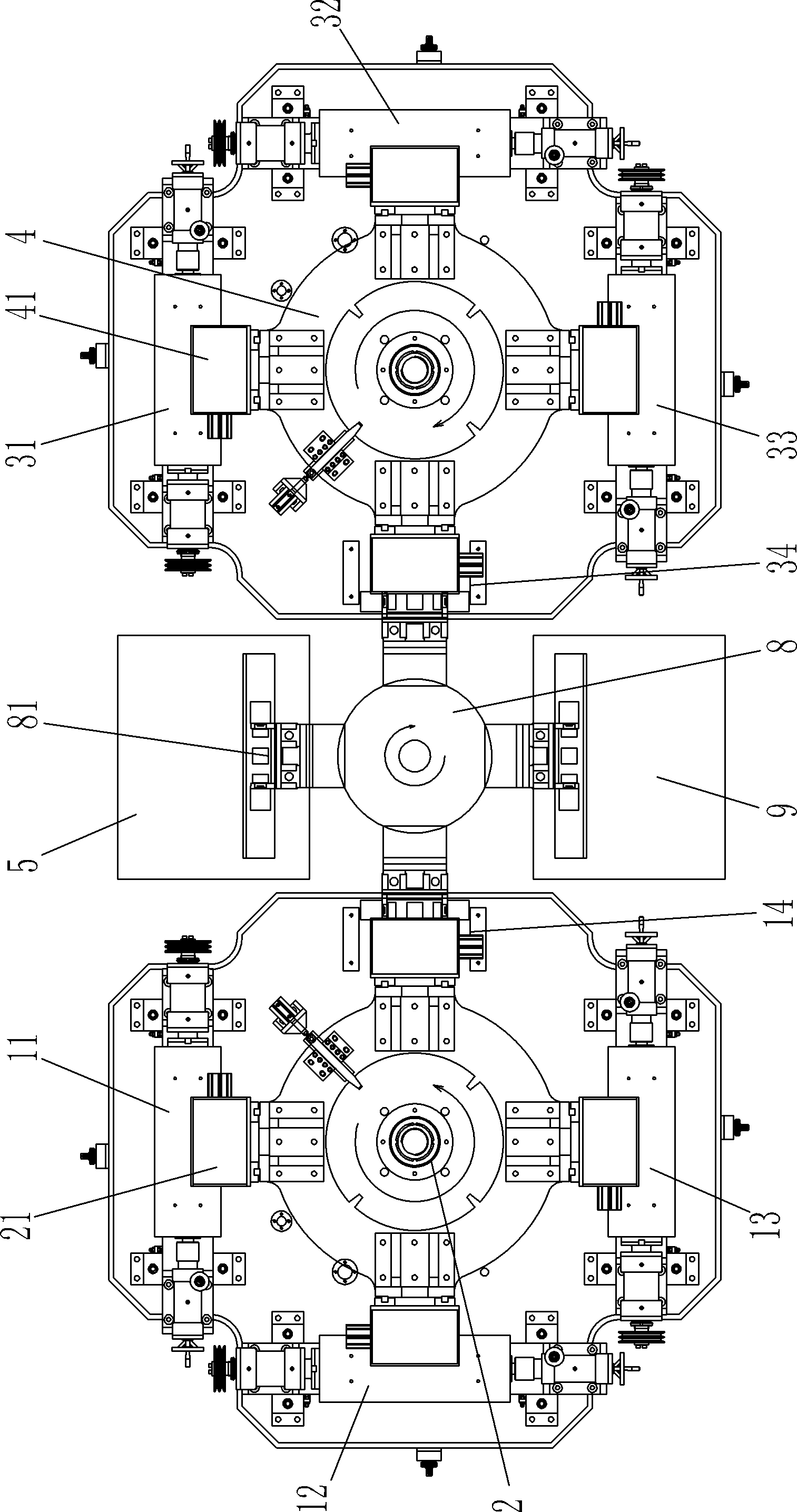

[0028] like figure 2The shown automatic grinding and polishing system for crystal blanks includes: a first rotating frame 2, around the first rotating frame 2, there are two upper hemisphere grinding stations 11 for grinding the upper hemisphere of the crystal blank. , 12 and an upper hemisphere polishing station 13 for polishing the upper hemisphere of the crystal blank, the first rotating frame 2 can be rotated and positioned and is provided with four heads 21; the second rotating frame 4 is rotated around the second The frame 4 is provided with two lower hemisphere grinding stations 31 and 32 for grinding the lower hemisphere of the crystal blank and a lower hemisphere polishing station 33 for polishing the lower hemisphere of the crystal blank. The second rotation The rack 4 can be rotated and positioned and is provided with four machine heads 41; the loading and unloading station 9 is provided with a loading and unloading material that can remove the crystal blank from t...

Embodiment 3

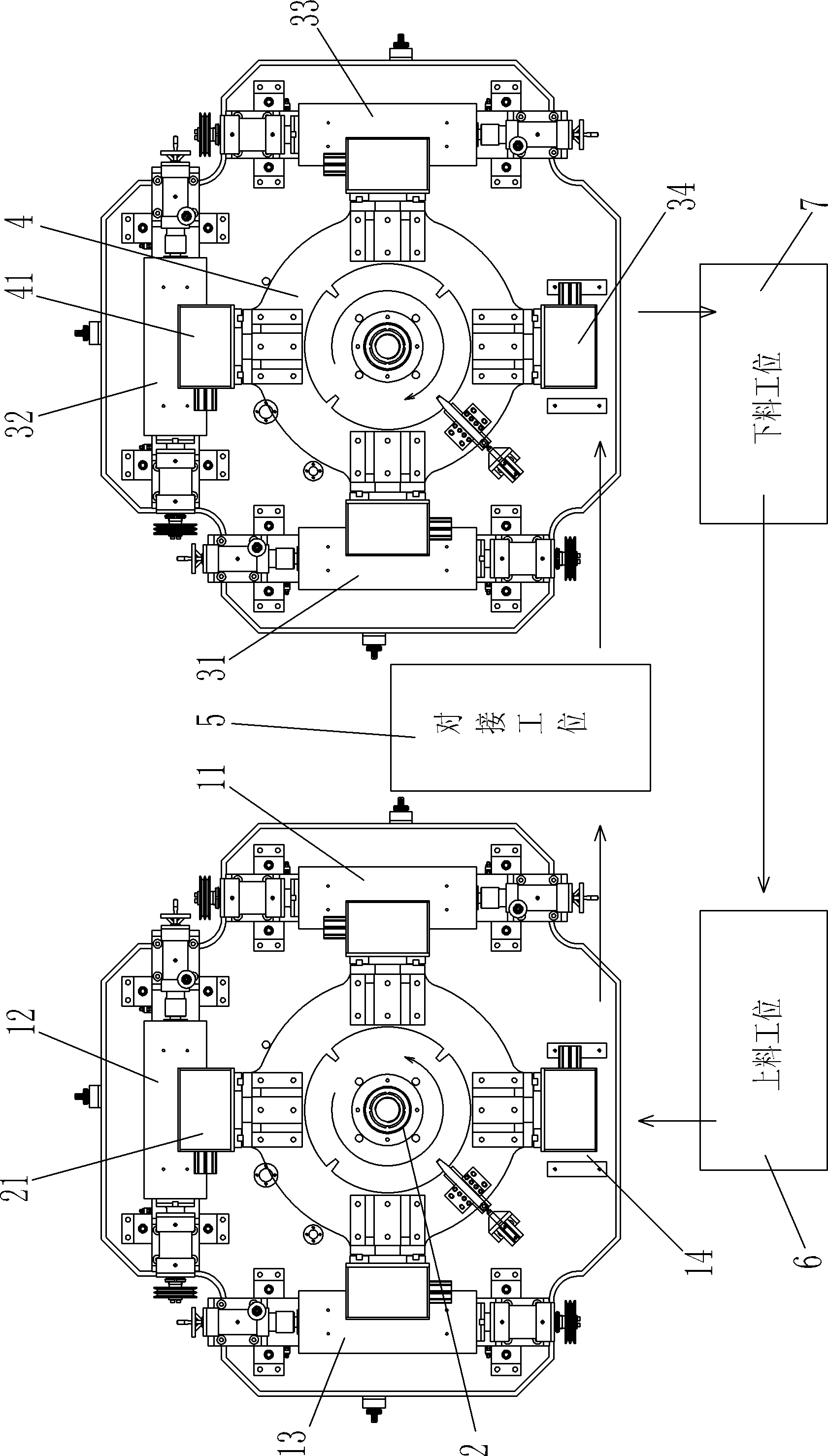

[0032] like image 3 The shown automatic grinding and polishing system for crystal blanks differs from Embodiment 1 only in that:

[0033] The transfer mechanism includes five manipulators capable of picking up and putting down clamps, and these five manipulators are respectively along the top of the loading station 6 to the top of the head of the first rotating frame 2 (located on the waiting station 14), the first rotating frame. 2 above the machine head (located on the waiting station 14) to above the docking station 5, above the docking station 5 to above the head of the second rotating frame 4 (located on the waiting station 34), and above the second rotating frame 4 Five fixed rails from the top of the machine head (located on the waiting station 34 ) to the top of the unloading station 7 , and from the unloading station 7 to the top of the loading station 6 run back and forth. Other mechanisms and working processes are similar to those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com