Folding movable concrete stirring station

A mixing plant and concrete technology, applied in the field of folding mobile concrete mixing plants, can solve the problems of difficulty in equipment transportation, affecting the service life of production efficiency equipment, time-consuming and laborious disassembly and installation, and achieving compact structure, improved service life, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

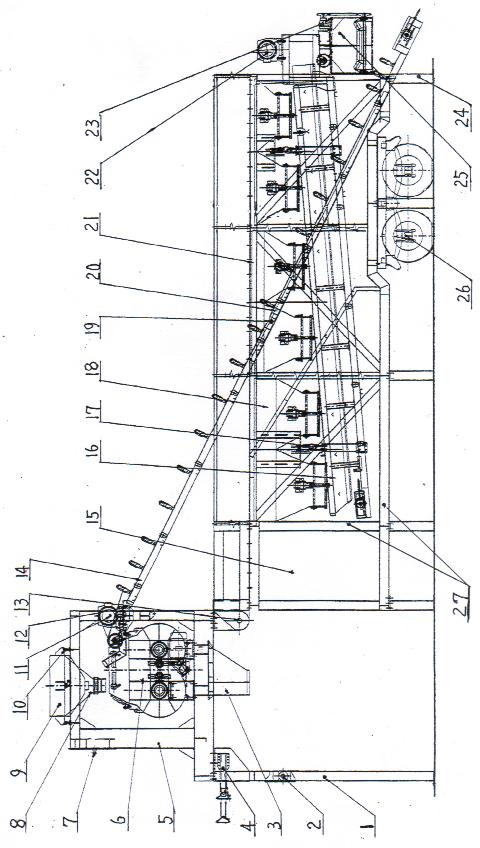

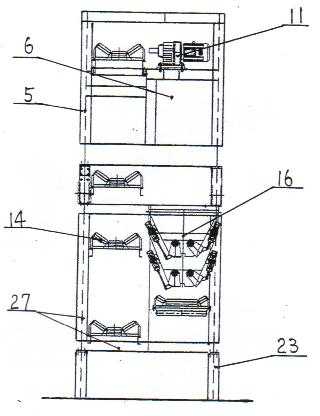

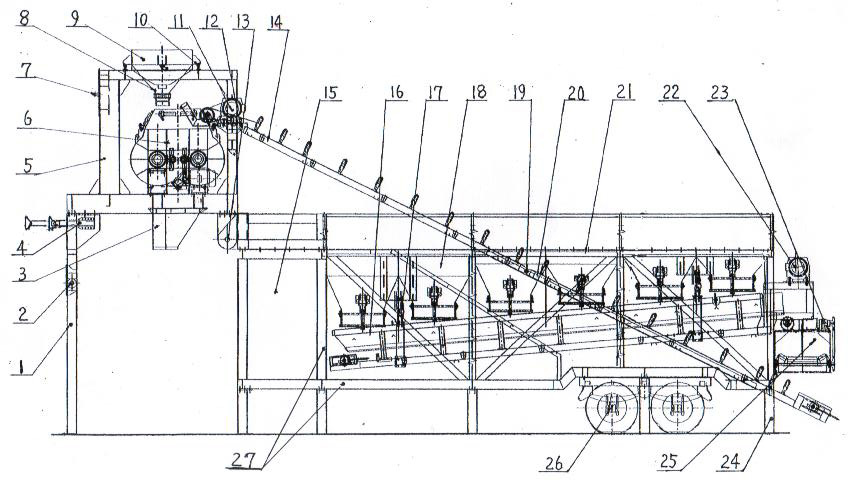

[0010] Examples, see attached figure 1 , 2 , the folding mobile concrete batching plant is a frame 27 fixed above several fixed legs 24, and a walking system 26 is installed under the right side of the frame 27. On the right side end of frame 27, adorn transitional belt conveyor 25 and transitional belt and drive unit 23, dress belt weighing scale drive unit 22 above transitional belt and drive unit 23. The belt measuring scale driving device 22 is connected with a belt measuring scale 16 installed obliquely, and tension sensors 17 are adorned on both sides of the belt measuring scale 16 . Six aggregate hoppers 18 with the same inclination as the belt weighing scale 16 are installed above the belt weighing scale 16, and cornices 21 are installed on the upper frame 27 of the aggregate hopper 18, and the cornices 21 and the aggregate hopper 18 are used as a storage bone together. The use of materials. Below the aggregate hopper 18 of the right end, the belt conveyor lower sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com