High-temperature short vulcanization process for transverse rubber backstop

A high-temperature, fast and lateral technology, applied in the field of rubber lateral stop vulcanization process, can solve the problems of long vulcanization time, low production efficiency, substandard product performance, etc., and achieve the effect of convenient production process, improved production efficiency, and shortened vulcanization time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

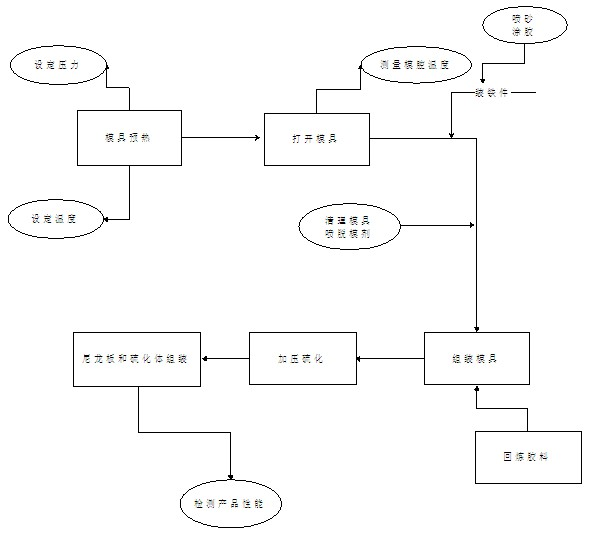

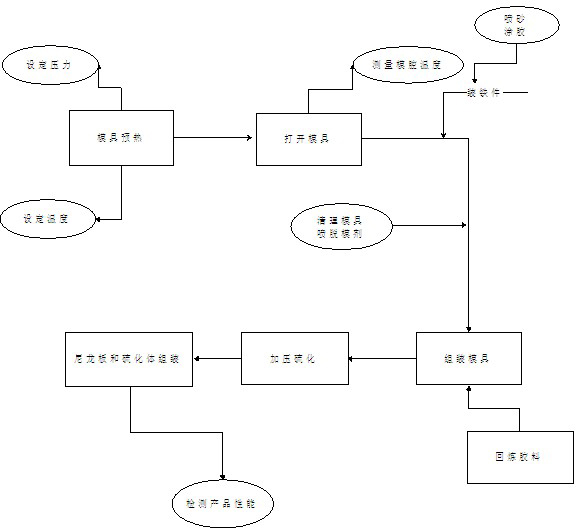

[0018] Embodiment one: refer to figure 1 , the production process of the rubber lateral stopper is carried out according to the following steps:

[0019] A: Select a 100T plate vulcanizing machine, set the temperature of the upper plate to 175°C, and set the temperature of the lower plate to 165°C. Then the production mold is placed on the flat vulcanizer, the pressure of the flat vulcanizer is set to 18MPa, and it is guaranteed that the mold is preheated for 3 hours.

[0020] B: The bottom plate of the rubber stop is put into the steel shot blasting machine for 15 minutes; the hard stop is put into the quartz sand blasting machine for 12 minutes.

[0021] C: Use the glue protection tool to protect the bottom plate and hard stop processed in the B process, and then paint the primer and surface glue. The coating thickness of primer is 18μm, the drying temperature is 70℃, and the drying time is 30min. The coating thickness of the surface adhesive is 60 μm, the drying temperat...

Embodiment 2

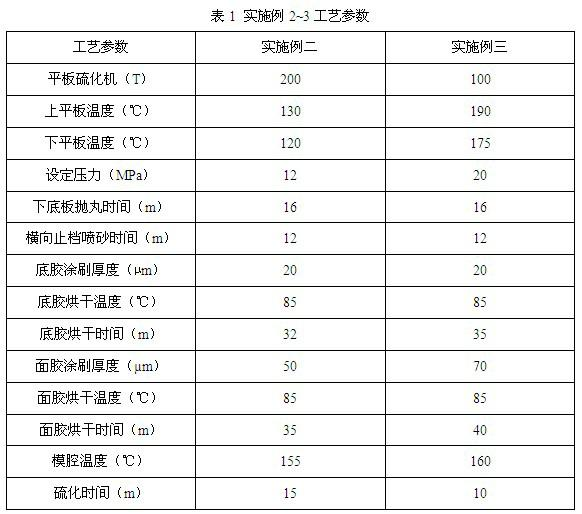

[0025] Embodiment 2: The preparation method is the same as that of Embodiment 1. The vulcanization parameters are shown in Table 1, and the test results of the obtained transverse stopper rigidity are shown in Table 2.

Embodiment 3

[0026] Embodiment 3: The preparation method is the same as that of Embodiment 1. The vulcanization parameters are shown in Table 1, and the test results of the obtained transverse stopper stiffness are shown in Table 2.

[0027]

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com