Spherical surface frame of airplane body and method for manufacturing spherical surface frame

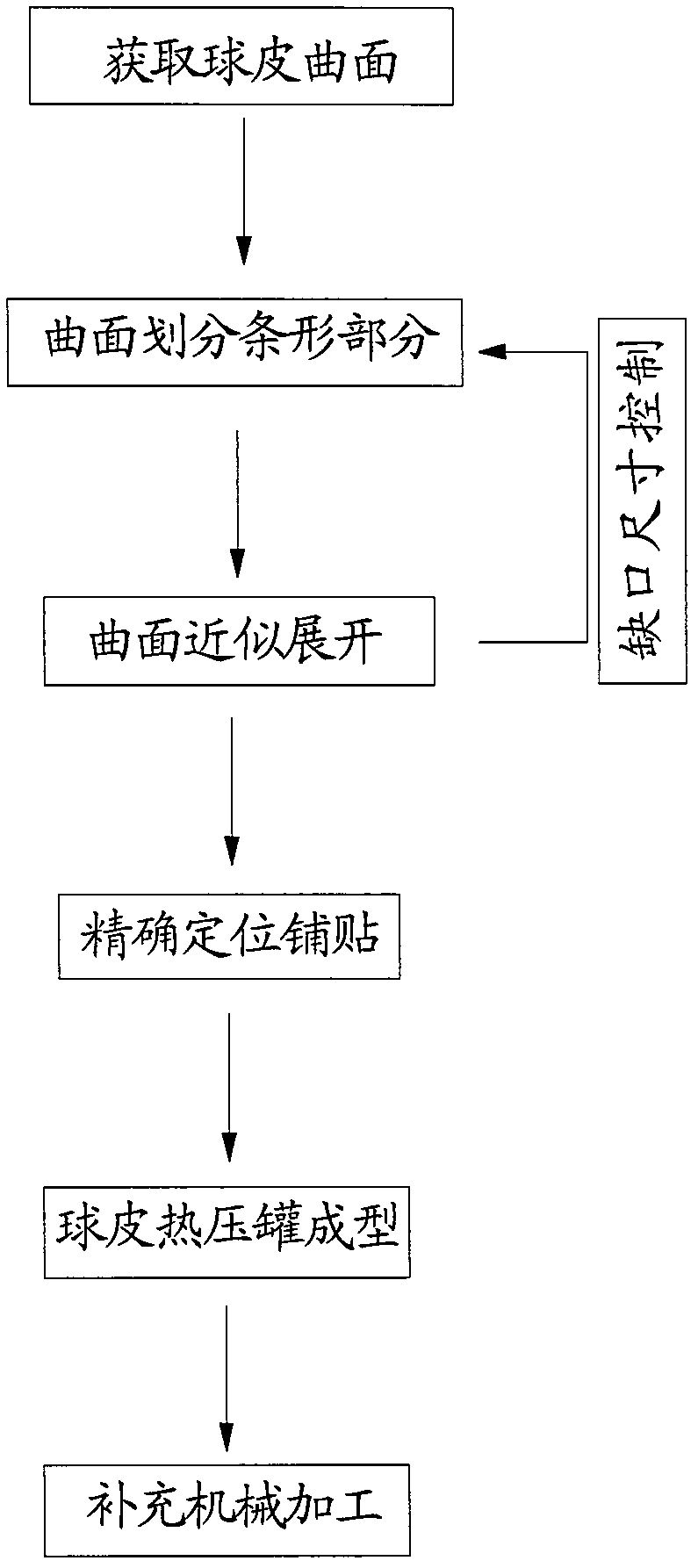

A manufacturing method and a technology for an aircraft fuselage, which are applied to the spherical frame of the aircraft fuselage and the manufacturing field thereof, can solve the problems of low fiber volume content, large safety factor, large porosity of liquid forming products, etc., and achieve the effect of solving the problem of precision manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

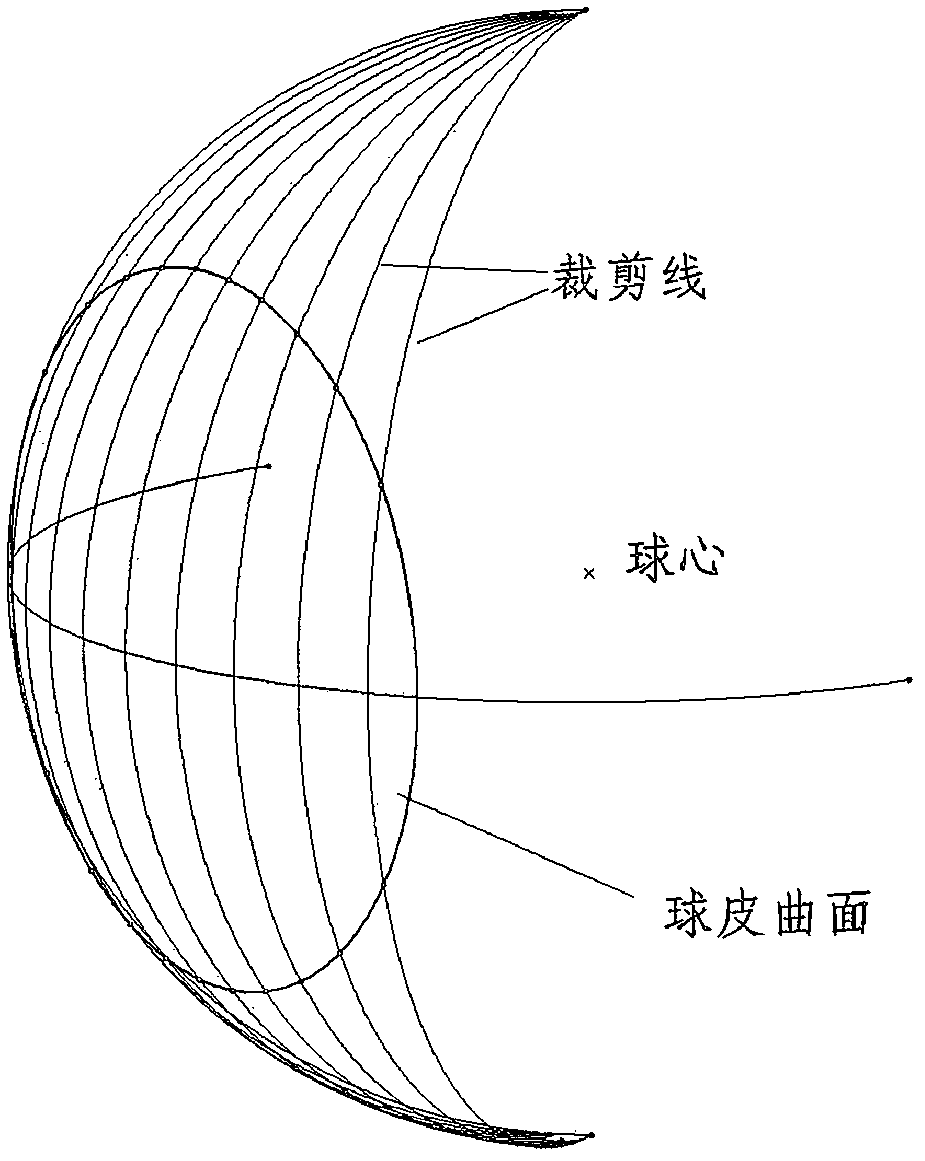

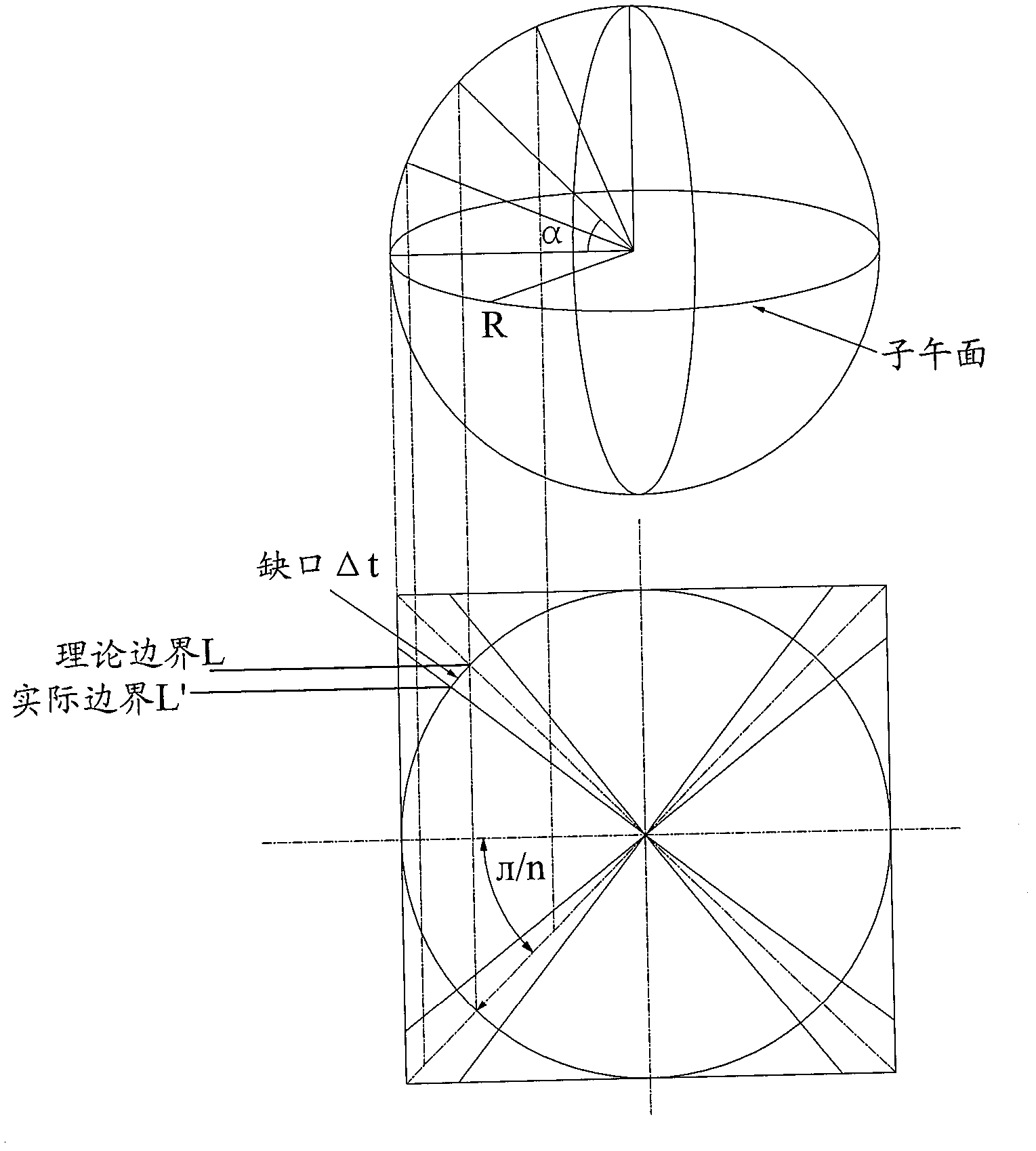

[0047] After obtaining the curved surface of the ball skin (assuming that the radius of the sphere where the curved surface is located is 2200mm), according to the width of the one-way belt (assumed to be 300mm) and the circumference of the meridian of the surface, it is determined that the spherical surface needs to be divided into at least 11 pieces, and the n value of the sphere corresponding to the curved surface of the ball skin is 49. According to the gap Δt=Rcosα(tgл / n−л / n), the maximum gap Δt is 0.198mm (α=0, on the meridian plane). Since the size of the notch is very small, according to the size of the largest notch on the meridian plane, the plane expanded with equal area is corrected to increase its width by 0.2mm, and the one-way tape is cut according to the corrected expansion diagram.

[0048] After determining the unfolding method of the single-layer curved surface, according to the thickness requirements of the structure and the thickness of the single-layer pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com