Method for manufacturing three-dimensional embossment

A technology of three-dimensional relief and embossment, which is applied in the field of making three-dimensional relief, can solve the problems of inflexible concept design and production operation, inconvenient handling of relief, and large space occupation, so as to achieve flexible and convenient design and production of relief, strong three-dimensional effect, and occupying a large area. The effect of small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

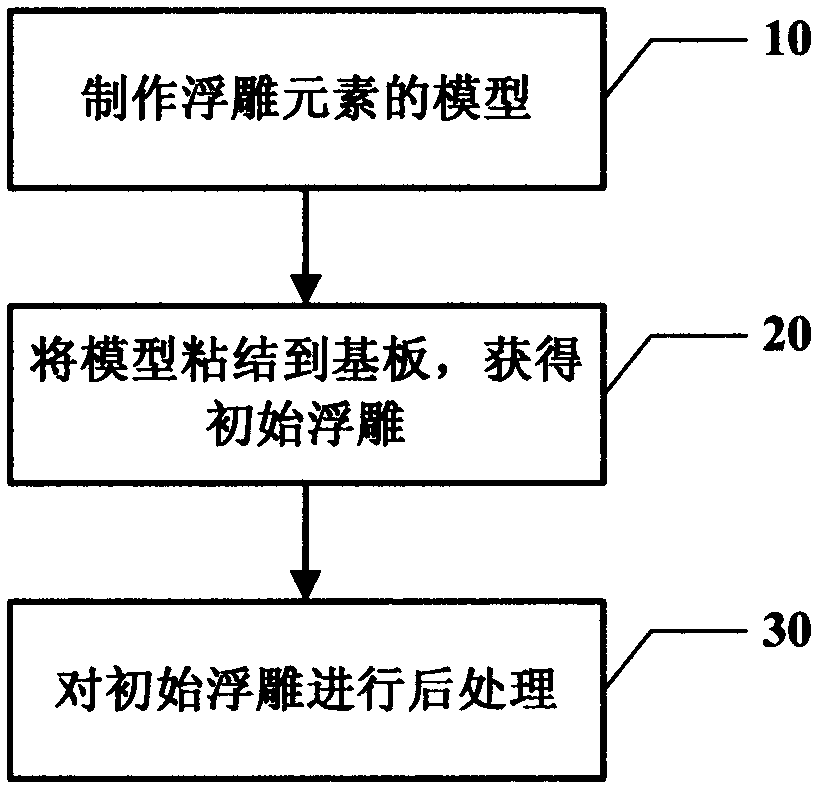

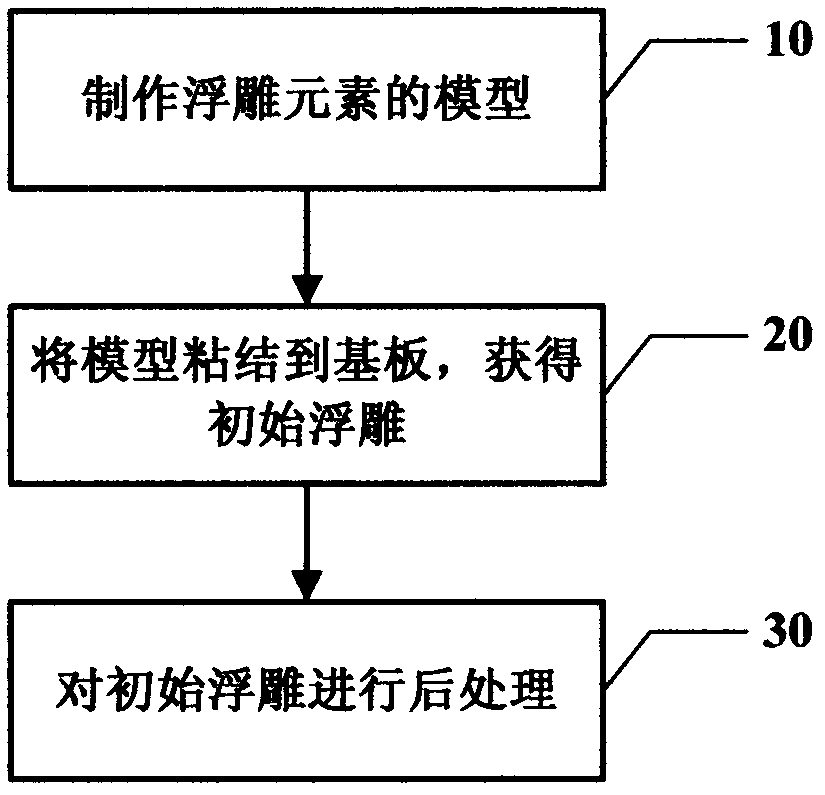

[0017] Such as figure 1 As shown, in one embodiment of the present invention, a method for making a three-dimensional relief includes step 10, step 20 and step 30.

[0018] Step 10: Make a model of the relief element;

[0019] A relief can be composed of multiple identical or different elements, such as various animals, plants, figures, mountains, water and so on. Of course, it can also be various other content elements that make up the relief. Herein, the various content elements constituting the relief are collectively referred to as relief elements. For a relief, the relief elements can be flexibly divided according to the actual situation or the convenience of production.

[0020] In the embodiment of the present invention, firstly, a model of the relief elements constituting the relief is made. Models of these relief elements can be made of the same material, such as resin, etc.

[0021] Step 20: Bonding the model to the substrate to obtain the initial relief;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com