Economical turning repair wheel

An economical and wheel-based technology, which is applied in the direction of wheels, wheel manufacturing, and wheels characterized by rail running parts, can solve the problem of large amount of wheel tread repair, so as to improve the turn repair cycle, ensure stability, and reduce maintenance workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

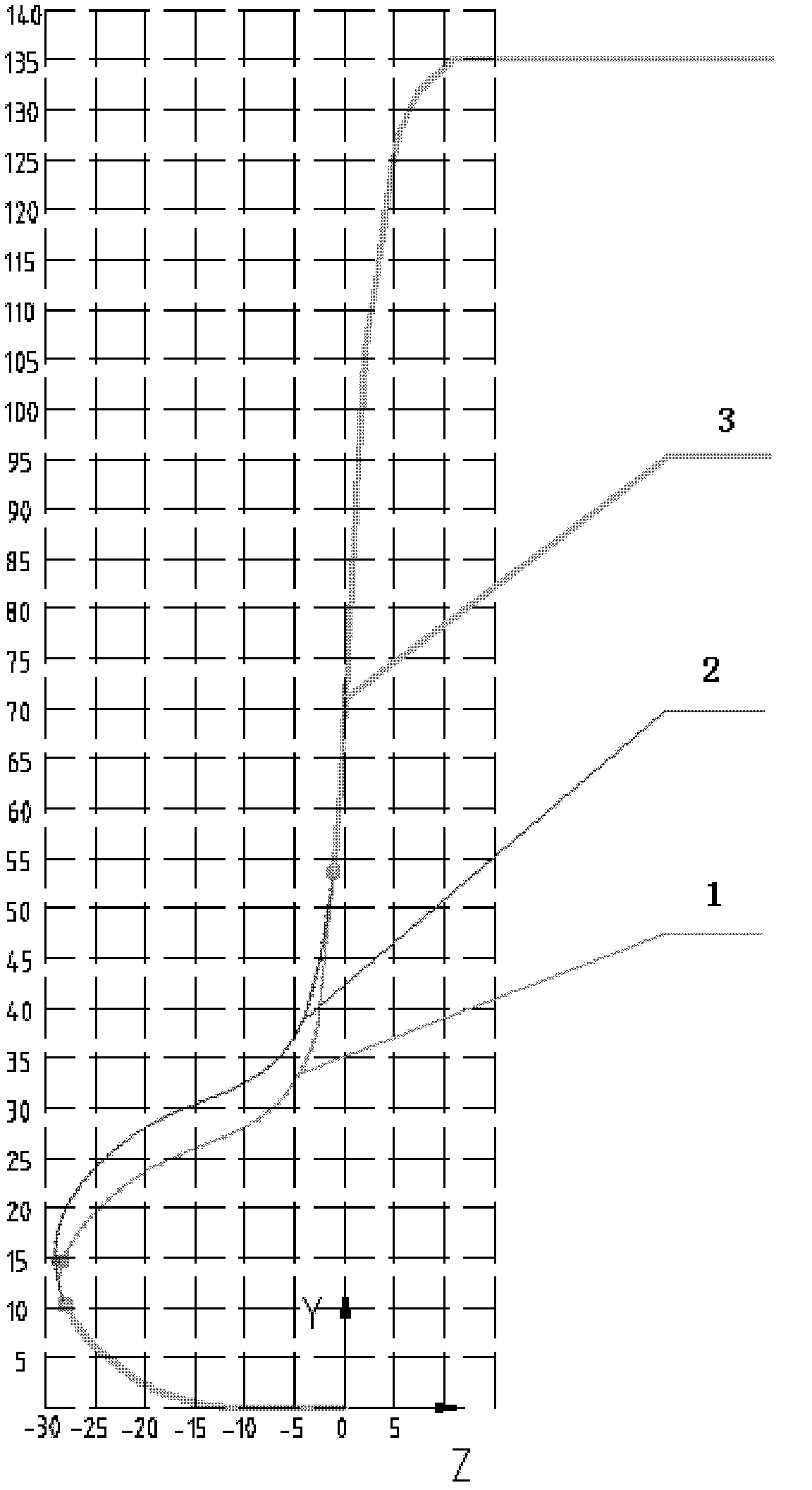

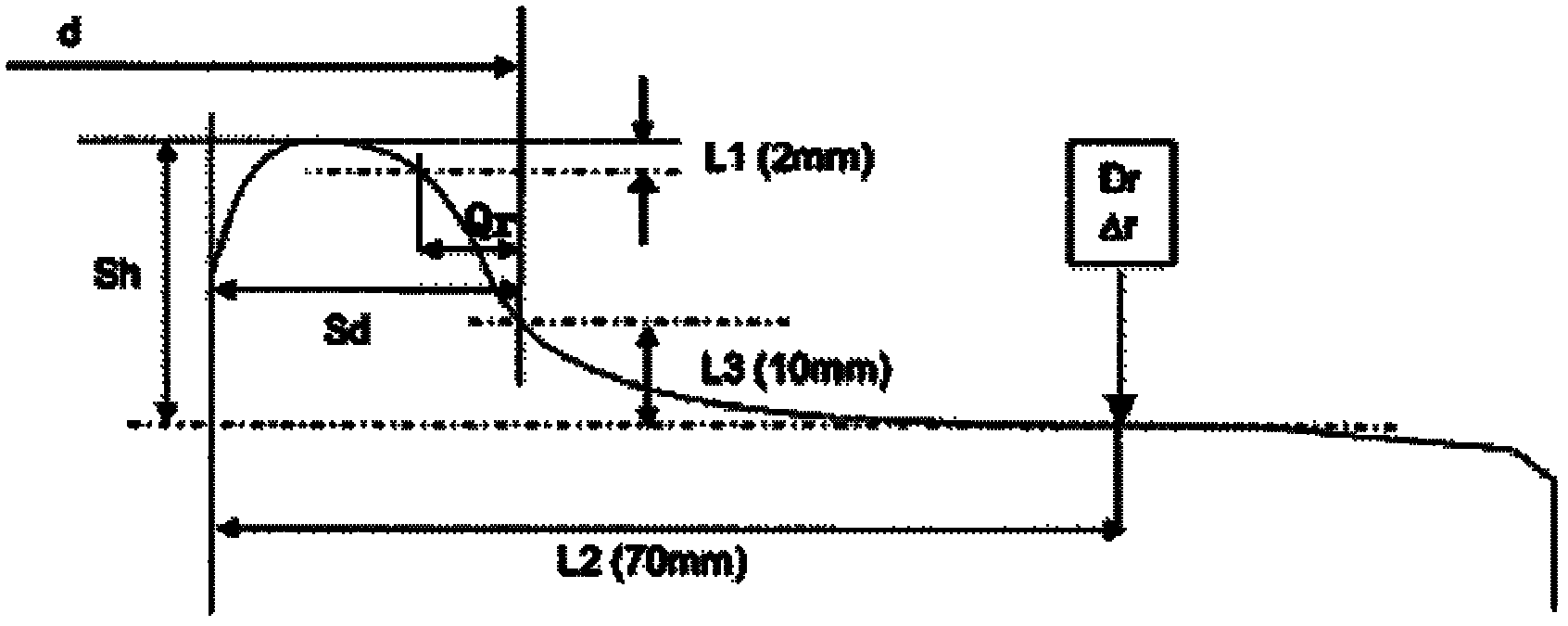

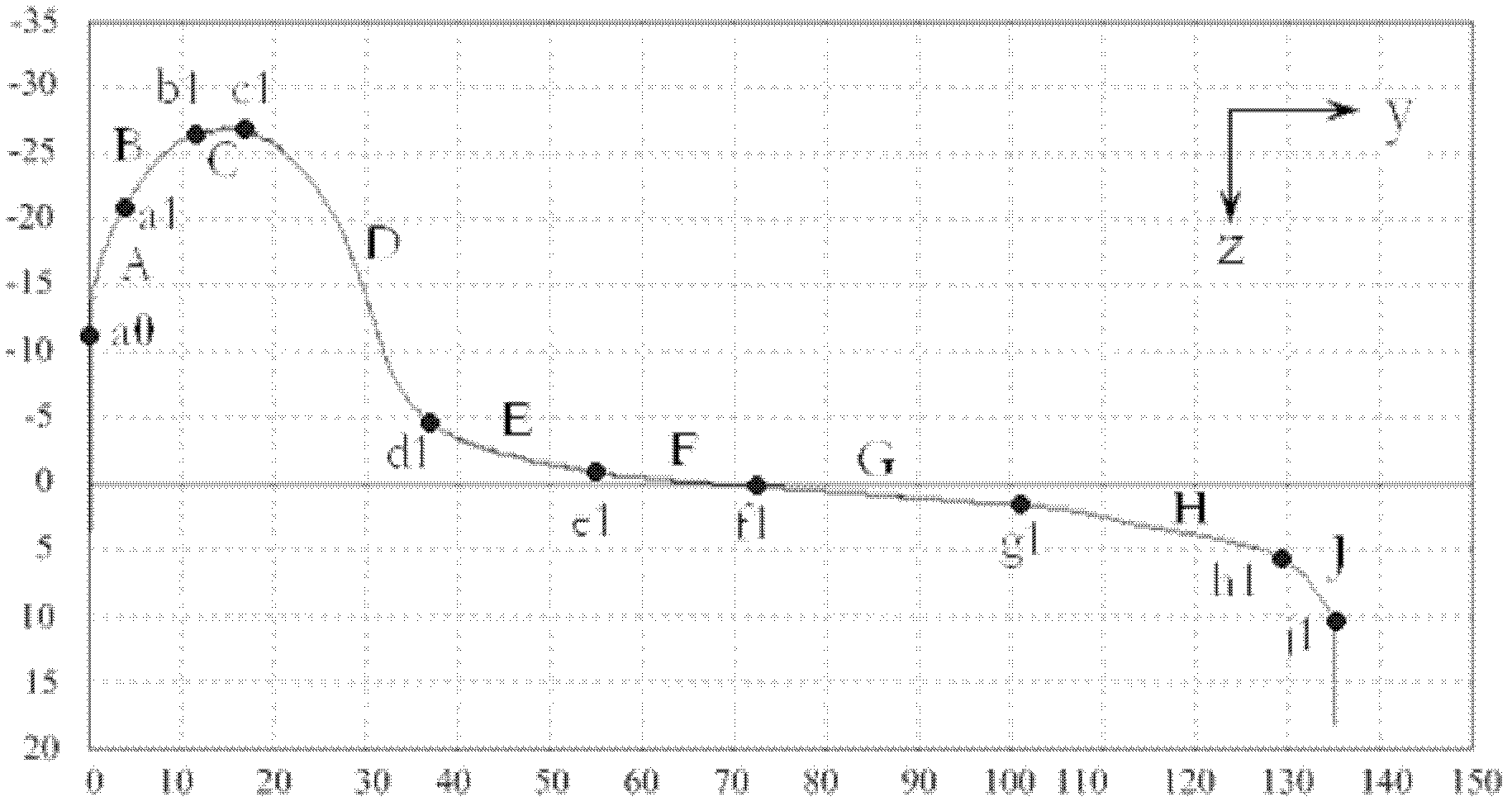

[0022] refer to figure 1 , 2 3. The XP55-28 economical refurbished wheel tread is based on retaining the A, B, D, F, G, H, J curve section 3 of the existing XP55 tread profile, and the original XP55 tread from the rim apex The feature section 2 is translated 4.5mm along the negative direction of the Y axis within 16.5mm of the rolling circle (y=70, z=0). Since the smoothness of the curve is damaged due to the translation, two quaternary transition curves are adopted. Segment B, D, and D, F are smoothly connected by segment E and E curve segment to obtain XP55-28 tread characteristic segment 1. The rim thickness Sd of XP55-28 tread is 28mm, the rim height Sh is 29mm, and the Qr value is 10.5 mm, Dr, Δr is a point on the radius of the rolling circle, L2 is the distance from the position of the rolling circle to the inside of the wheel, L1 is the distance from the measuring point of the rolling circle to the apex of the rim, L3 is the vertical distance from the Qr value measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com