Control device for full-automatic steering transmission of pure light mineral cotton acoustic board

A mineral wool sound-absorbing board, fully automatic technology, applied in the conveyor control device, transportation and packaging, conveyor objects and other directions, can solve the problems of stagnation, blocking, accumulation, blocking, etc., to avoid disorder and blocking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

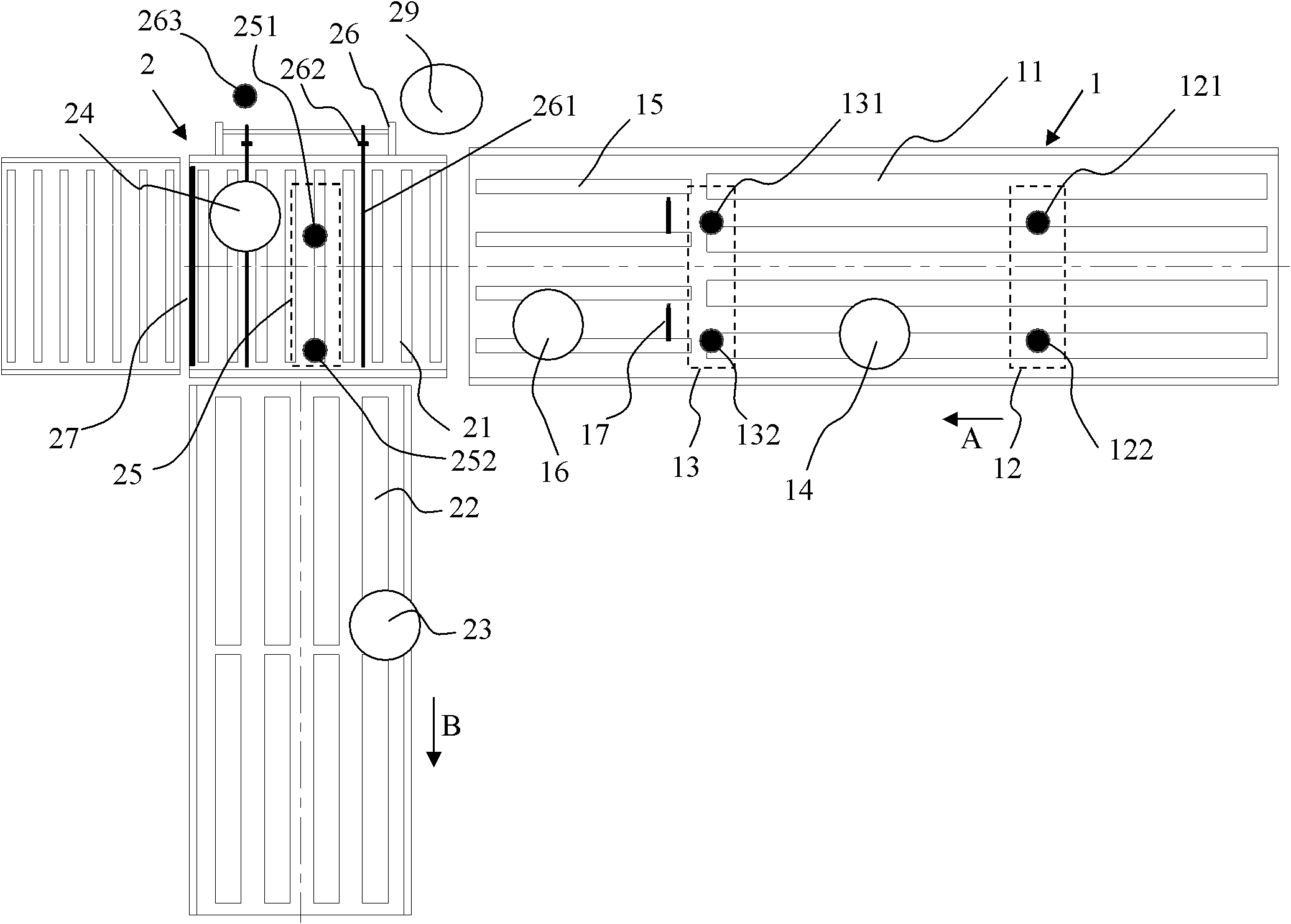

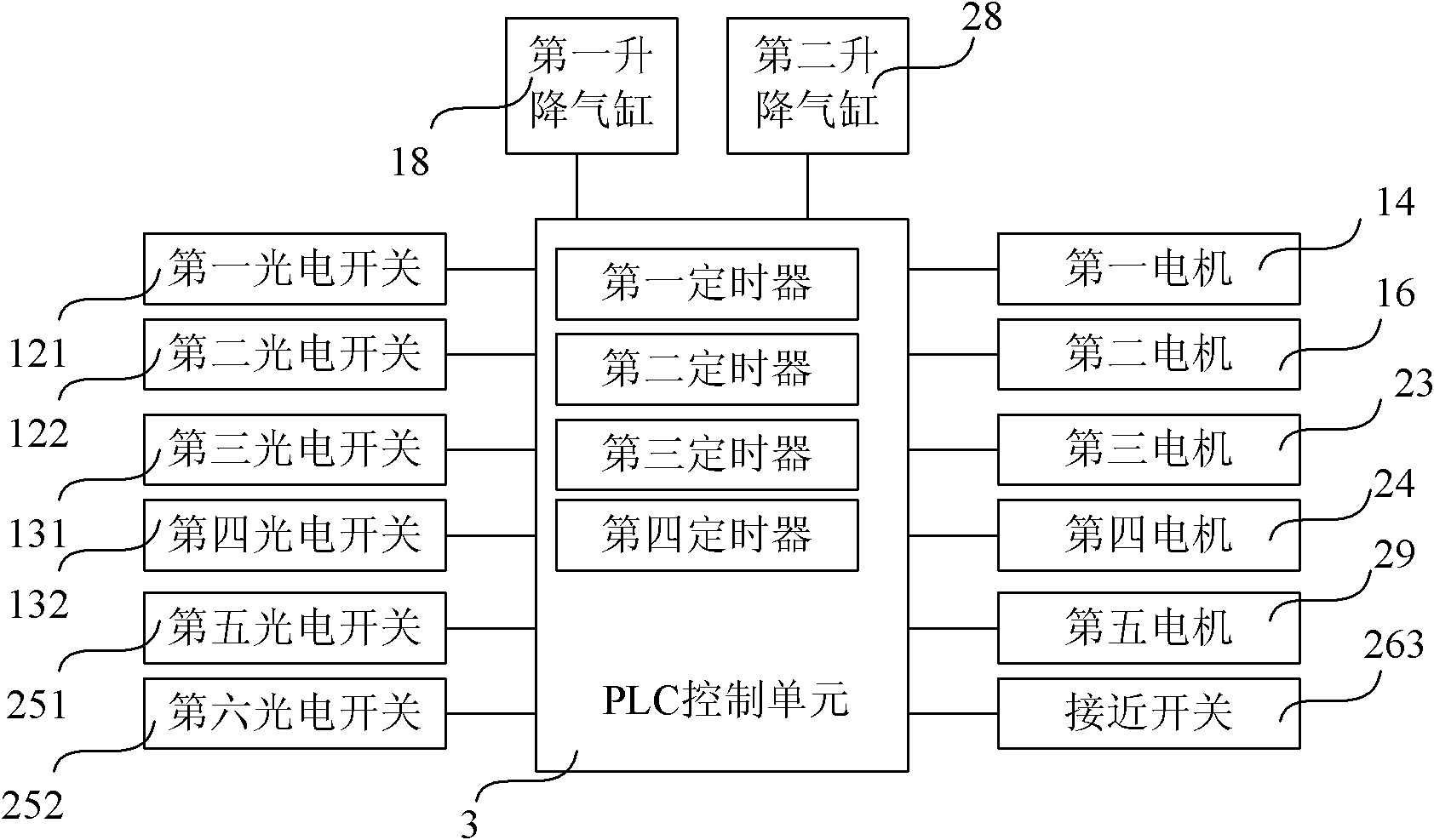

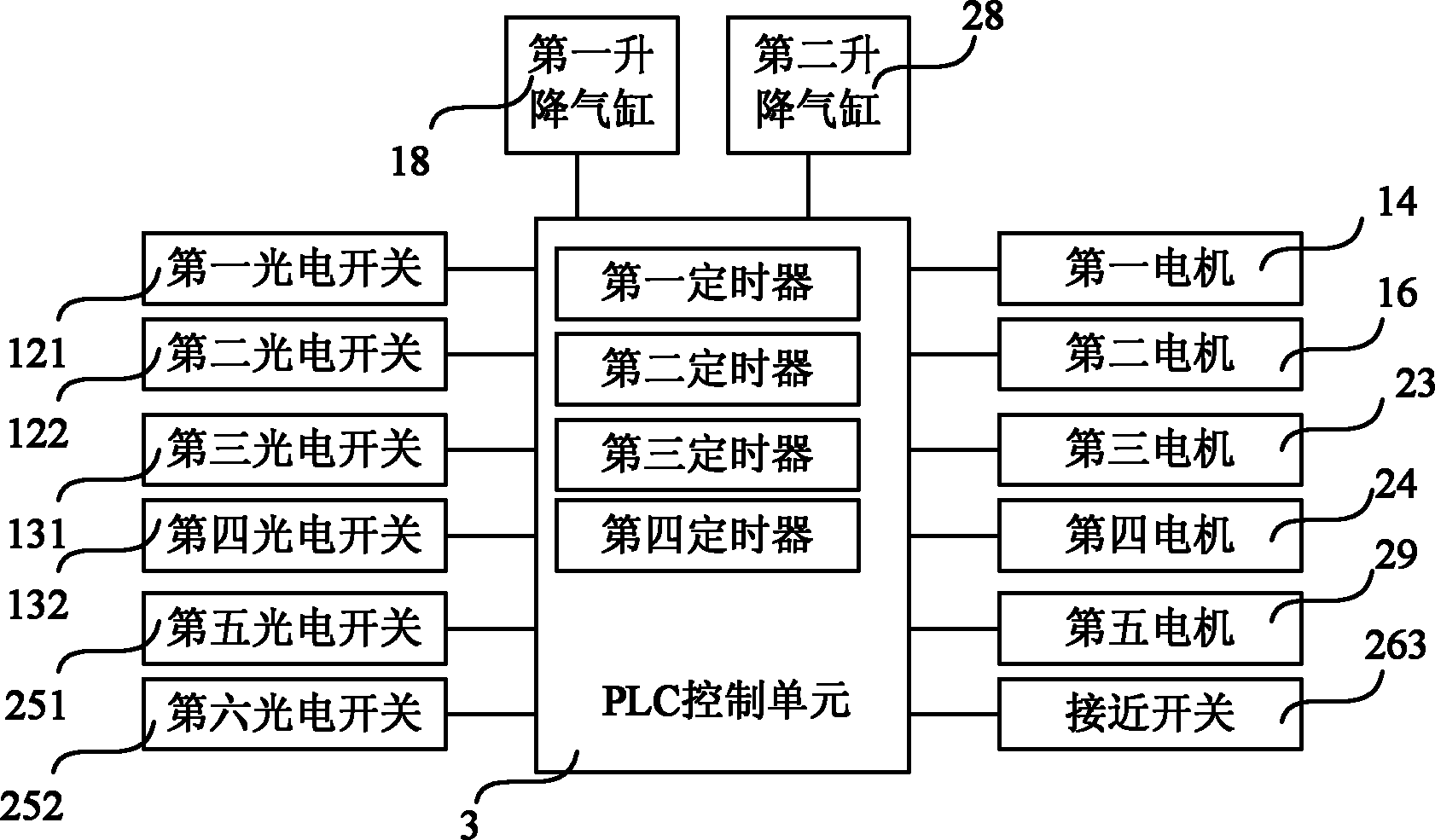

[0015] Such as Figure 1~2 As shown, the present invention includes: PLC control unit 3, original plate output section 1 and finishing input section 2 whose transmission direction (direction of arrow B) is perpendicular to the transmission direction (direction of arrow A) of this original plate output section 1. in;

[0016] The original plate output section 1 further includes a first belt transmission unit 11 and a second belt transmission unit 15 arranged in sequence on the transmission direction, and the first photoelectric switch unit at a distance from an appropriate position is arranged side by side on the first belt transmission unit 11 along the transmission direction 12 and the second photoelectric switch unit 13. In the embodiment of the present invention, the first photoelectric switch unit 12 includes a first photoelectric switch 121 and a second photoelectric switch 122 arranged in parallel, and the second photoelectric switch unit 13 includes a third photoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com