A direct-fired intelligent gas tunnel furnace

A direct-fired, tunnel furnace technology, applied in the field of tunnel furnaces, can solve the problems of low intelligence, high site requirements, uneven heating of baked products, etc., and achieve the effect of high intelligence and reduced longitudinal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

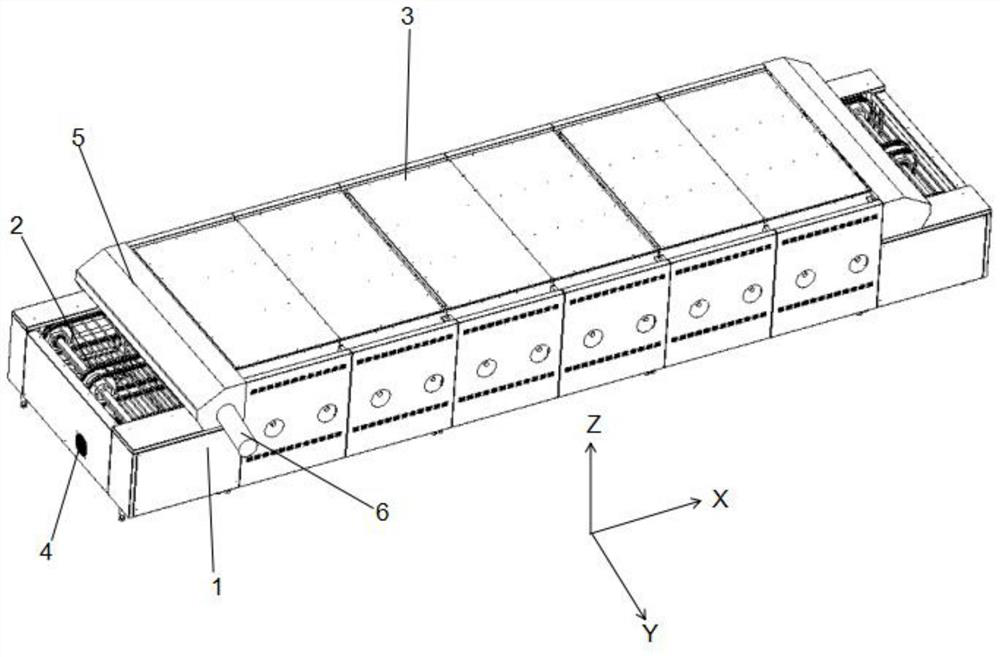

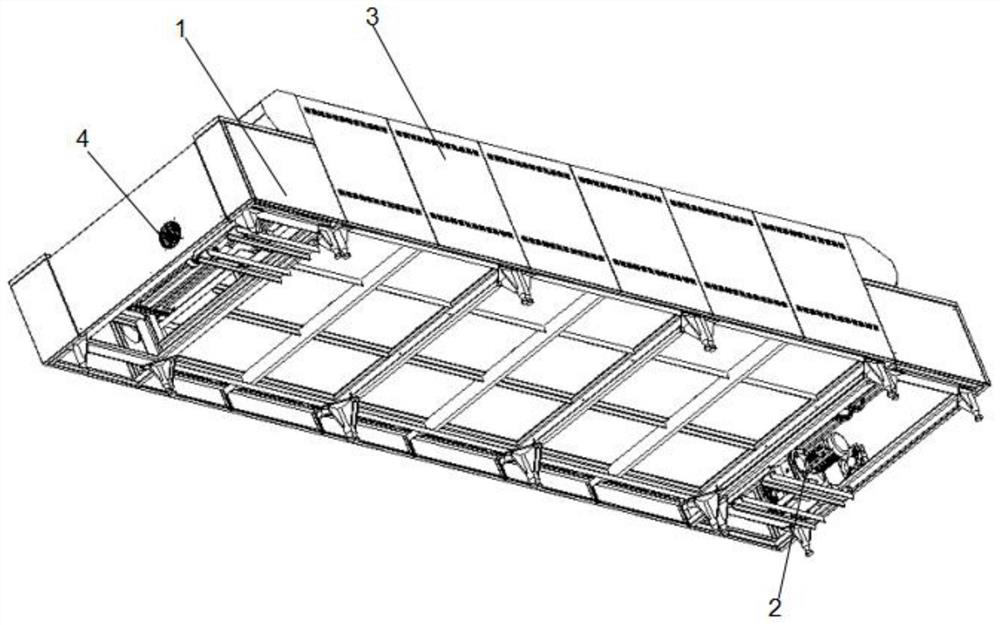

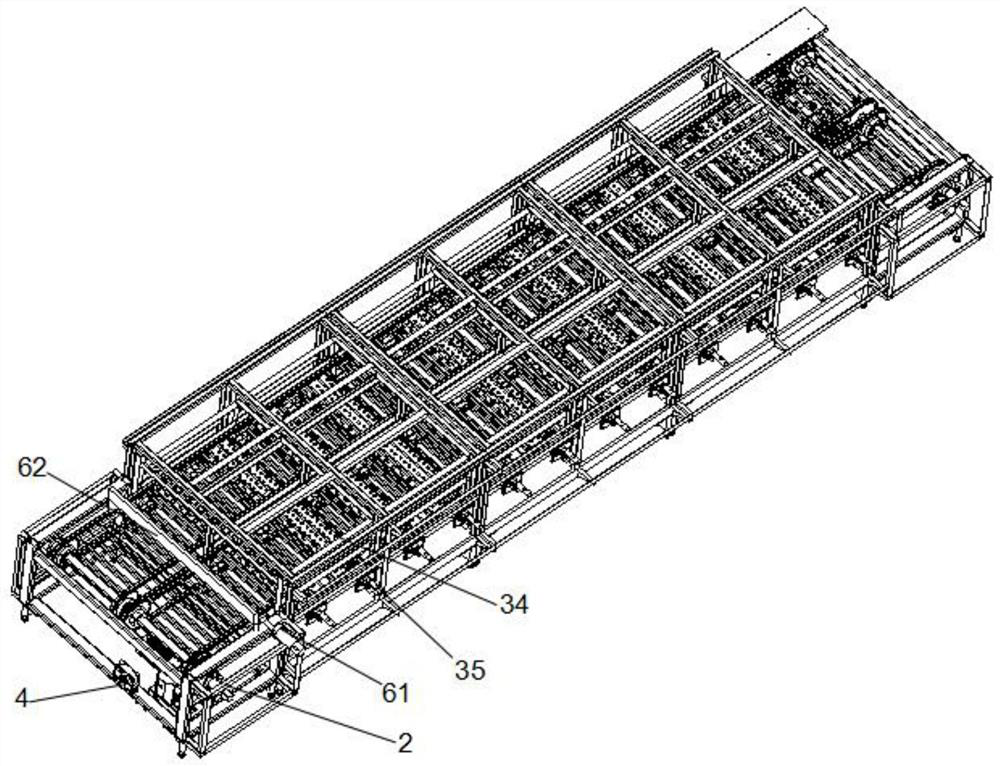

[0025] Embodiment: a direct-fired intelligent gas tunnel furnace.

[0026] refer to Figure 1 to Figure 5 As shown, a direct-fired intelligent gas tunnel furnace includes:

[0027] Rack 1;

[0028] The driving mechanism 2 installed at the front and rear ends of the frame 1, the driving mechanism 2 is composed of two first driving devices and second driving devices distributed in parallel along the Y direction and opposite driving directions, wherein the first driving device includes a first driving motor 21. The first transmission sprocket shaft 22 and the first transmission chain plate 23, the two first transmission sprocket shafts 22 are installed in parallel on the front and rear ends of the frame 1, and the first transmission chain plate 23 is installed on the front and rear two first transmission chains Between the axle rods 22, the first drive motor 21 is installed on the frame 1 and is connected with the first drive sprocket shaft rod 22 through a transmission chain. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com