Main amplitude mast of crawler crane and crane comprising mast

A technology of crawler cranes and cranes, which is applied to cranes, transportation and packaging, ships, etc. It can solve the problems that the main luffing mast cannot meet the length requirements and the structural size is limited, and achieve the effect of meeting the length requirements and design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

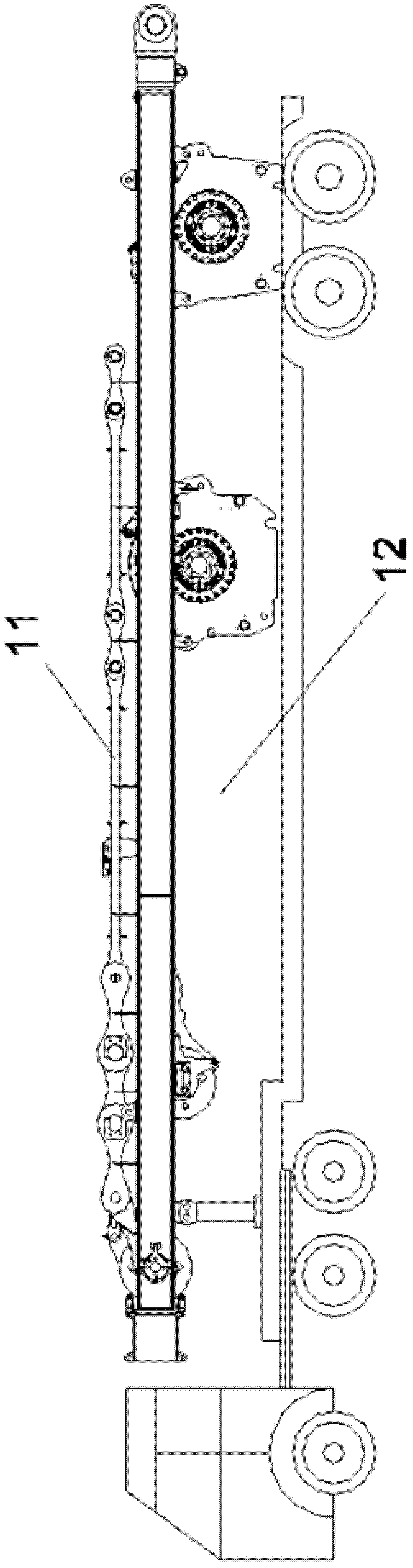

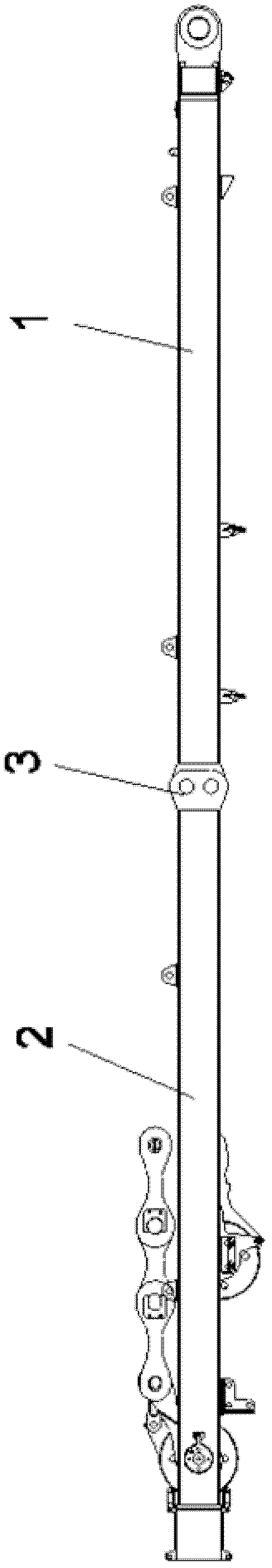

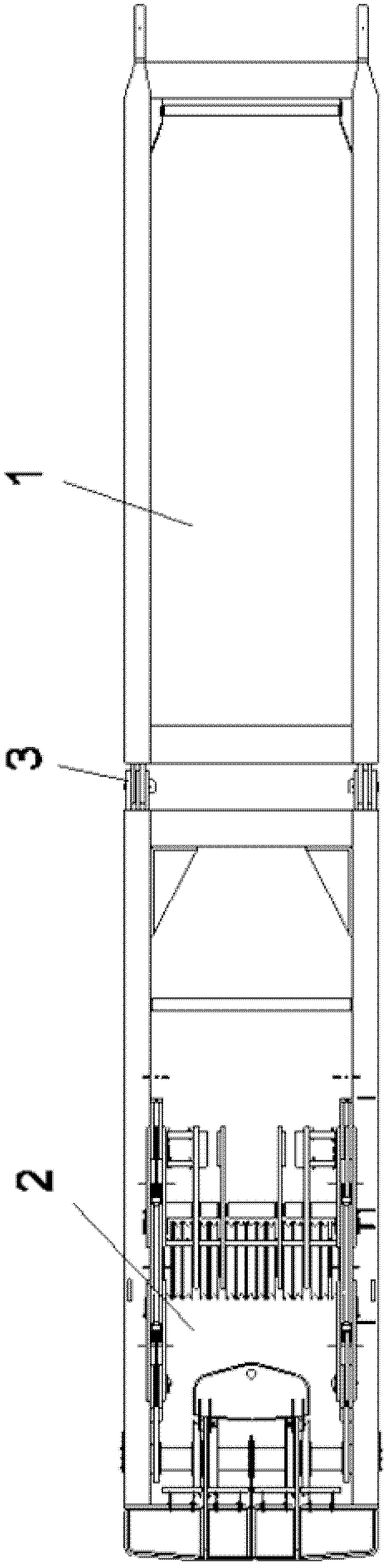

[0020] As shown in Figure 2(a) and Figure 2(b), the embodiment of the present invention provides a main luffing mast for a crawler crane, the main luffing mast is set on the crawler crane platform, wherein the main luffing The mast is composed of two parts, the upper module 1 and the lower module 2 , and the upper module 1 and the lower module 2 are connected together by a joint 3 . Preferably, the joints are connected by pins. As shown in Figure 3(a) and Figure 3(b), the joint 3 is disassembled during transportation, the upper module is transported together with the platform, and the lower module 2 is transported together with the winch mechanism, which can easily meet the transportation requirements and save transportation cost.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com