Preparation method of beta type ammonium tetramolybdate

A technology of ammonium tetramolybdate and ammonium molybdate, applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., can solve problems such as the influence of processing performance and the difficulty in controlling the transformation rate of β-type ammonium tetramolybdate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

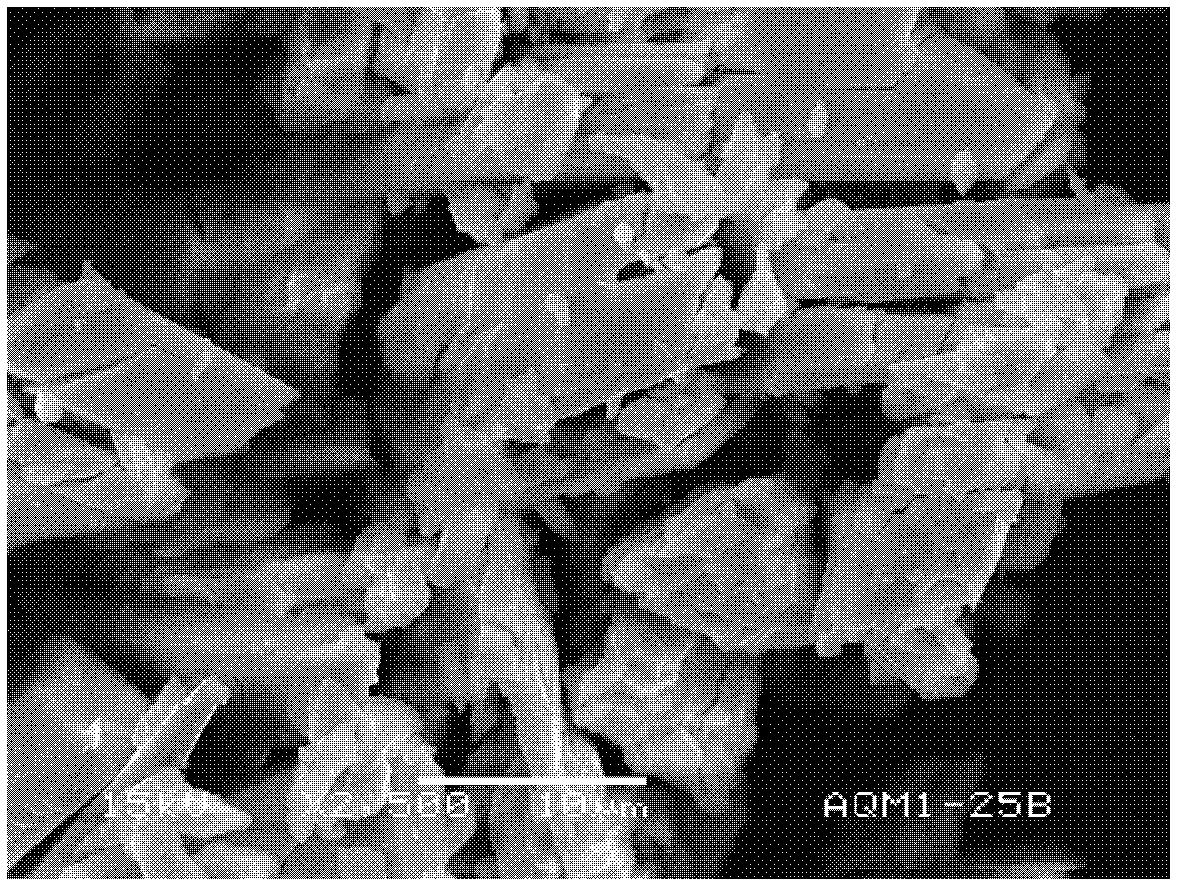

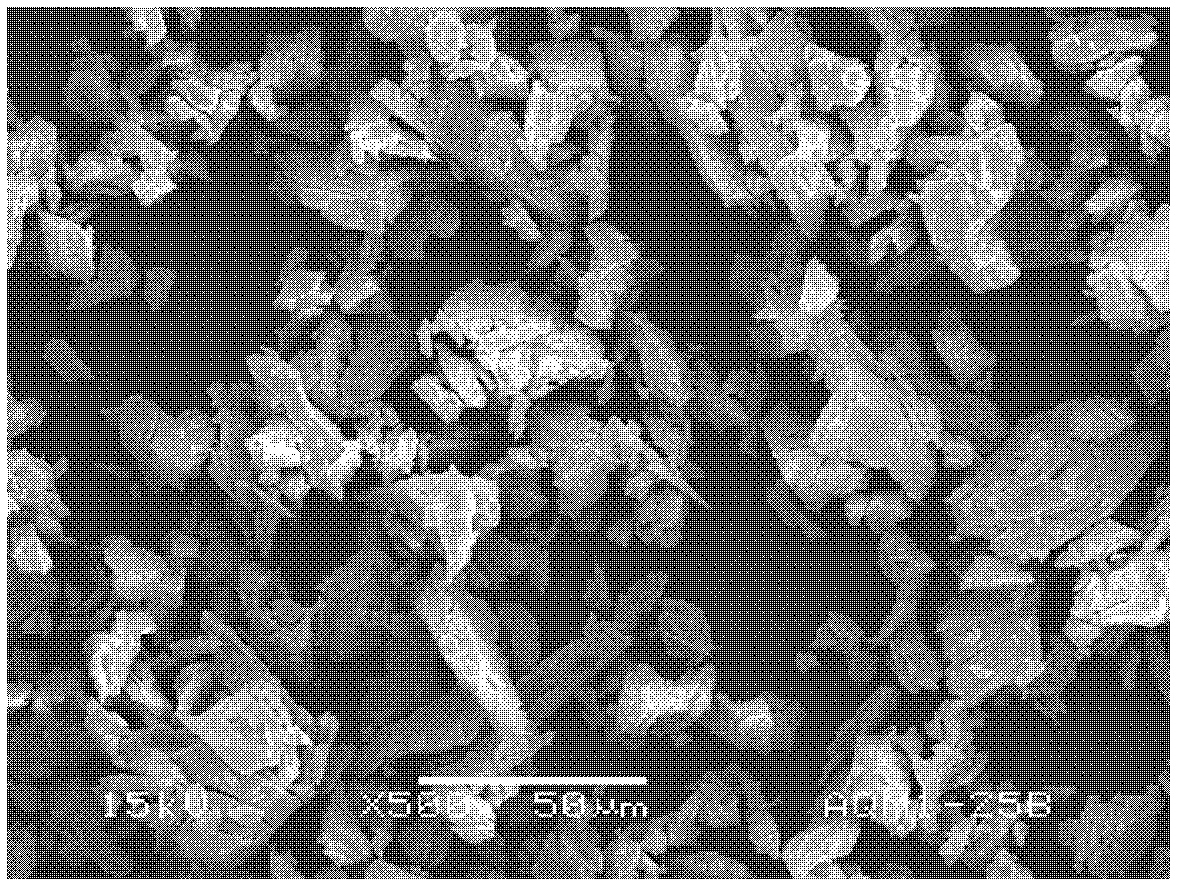

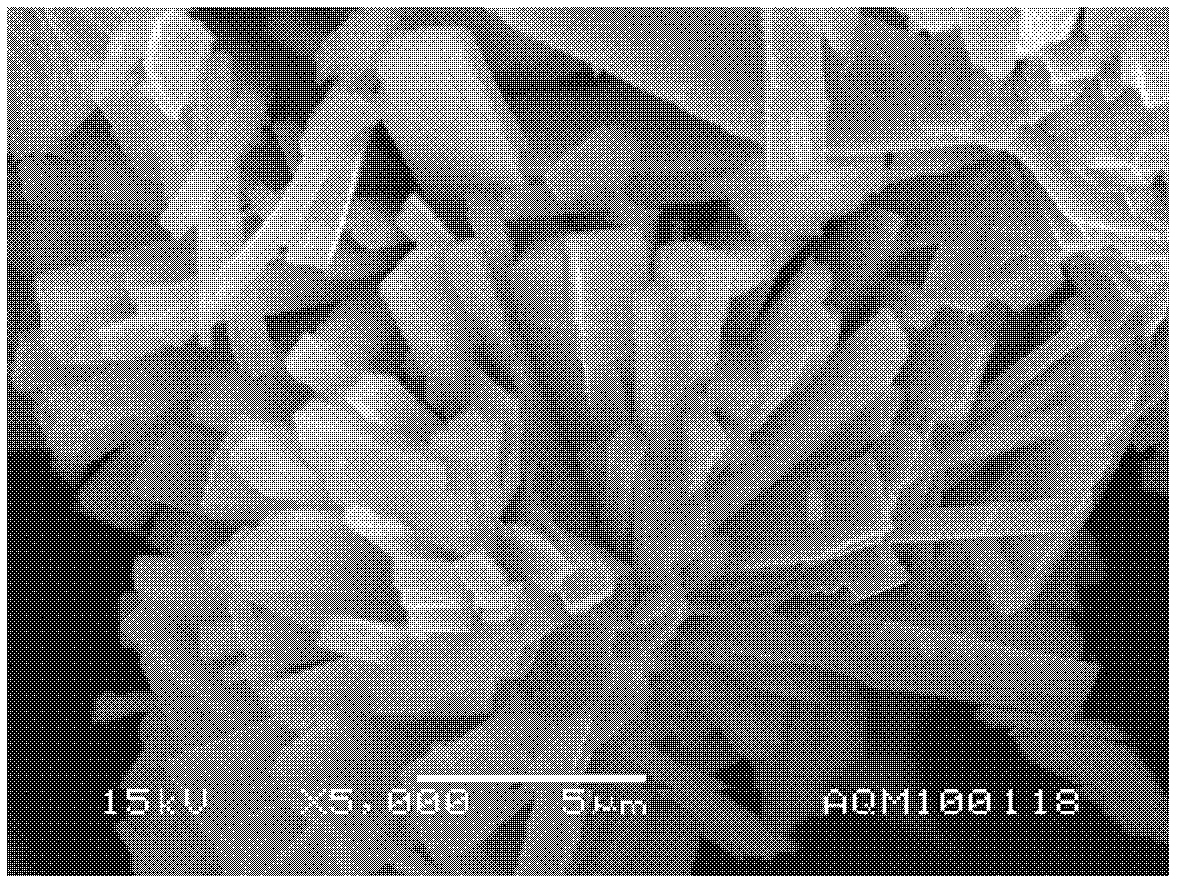

[0019] The preparation method of the β-type ammonium tetramolybdate of the present embodiment includes salt pretreatment of molybdenum oxide, preparation of ammonium molybdate solution, acid precipitation, transformation and drying steps; wherein, during acid precipitation, the specific gravity is 1.14-1.16 g / cm 3 The ammonium molybdate solution is filtered and poured into the acid precipitation crystallization tank, stirred and passed into nitric acid, and the pH value of the solution is checked at any time during the acid addition process. When the pH value of the solution reaches 4, the acid addition is stopped and the solution in the reactor is checked. Keep the temperature at 60°C±5°C, and then continue to add acid slowly; during this period of acid addition process, the acid addition speed should be strictly controlled, the pH value should be checked at any time, and the acid addition speed should be gradually slowed down according to the change of pH value, and finally c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com